THE IGNITION

SYSTEM

B

assembly,

capacitor,

cam,

rotor

arm

and their

associated

electrical

connections.

The

direction

of

rotation is

stamped

on

the

body.

The

upper

end

of

the

body

is

closed

by

a

bakelite

cap

which houses

the plug

lead

segments

and

the

HT.

lead

brush and

spring.

The

automatic

advance

mechanism

comprises

a

centrifugally

operated rolling

weight mechanism and

a

vacuum-operated

mechanism

which

together advance the

ignition point in

proportion

to

the

engine

speed and

load.

The

vacuum-operated

mechanism

has

a

vernier

adjustment

screw

to

enable small

adjustments

to

be made

to

suit

varying

grades

of fuel

or

to

satisfy

tuning requirements.

A

double-headed

arrow

marked

‘A’ and ‘R’

is

stamped

on

the

body

adjacent

to

the

vernier

screw.

A

fuel

trap

is

incorporated

in

the

vacuum

line

from the induction

manifold.

The

contact

breaker assembly

is

made

up

of

a

base plate

secured

to

the distributor body,

a

moving

contact

breaker

plate,

a

■xed

contact

breaker plate,

the

contact

breaker

points,

and

a

capacitor.

The

moving

plate

is

supported

on

the base plate by

two

nylon

pads,

which

minimizes

friction when the

automatic

advance

moves

the

plate.

A ‘C’

spring

anchored

to

a vacuum

control

spring

post

bears

against

the

under

side of the

base

plate

and

so

pre-tilts

the

moving

plate.

The

pressure

of

the

cam on

the

heel

of

the

contact

breaker

points

supplements

this

action

and

so

minimizes

rocking

of the

moving

plate

at

high

cam

speeds.

A

stud fixed

to

the under side of the

moving

contact

plate

engages

a

slot

in

the base plate

and

so

limits the

horizontal

movement

of the

moving

plate;

the

stud also

limits the

angle

of

tilt

of the

moving

plate.

The ■xed

contact

breaker plate

is

secured

by

a

screw

which

passes

through

a

slot

in

the

fixed plate.

A

notch

cut

in

the

free end

of

the plate

permits

the

engagement

of

a

screwdriver

for adjustment

purposes

when

setting

the

contact

breaker

points

gap.

The

distributor

is

secured

to

the

engine

by

a

split housing

plate and clamp

bolt. On

some

distributors the

clamp bolt

is

trapped and the

nut

free

and

on

others

the

nut

is trapped

and the bolt

is

free.

‘

Section

3.4

SERVICING THE DISTRIBUTOR

Contact

breaker

points

Examine

the

contact

breaker

points

and

if

they

are

found

to

be burnt

or

blackened

remove

them

as

described

in

Section

B.6

and clean

them

with

a

■ne carborundum

stone

or

emery-cloth.

After

cleaning,

remove

all

traces

of

dust and

grease

with

a

petrol-moistened

cloth.

Lightly

smear

the

contact

breaker

pivot

pin

with

molybdenized

non-creep

oil

or a

suitable

grease

and

re■t

the

points.

it is important

that

no

oil

or

grease

is

allowed

to

contaminate

the

contact

breaker

points.

MGB.

Issue4. 1329

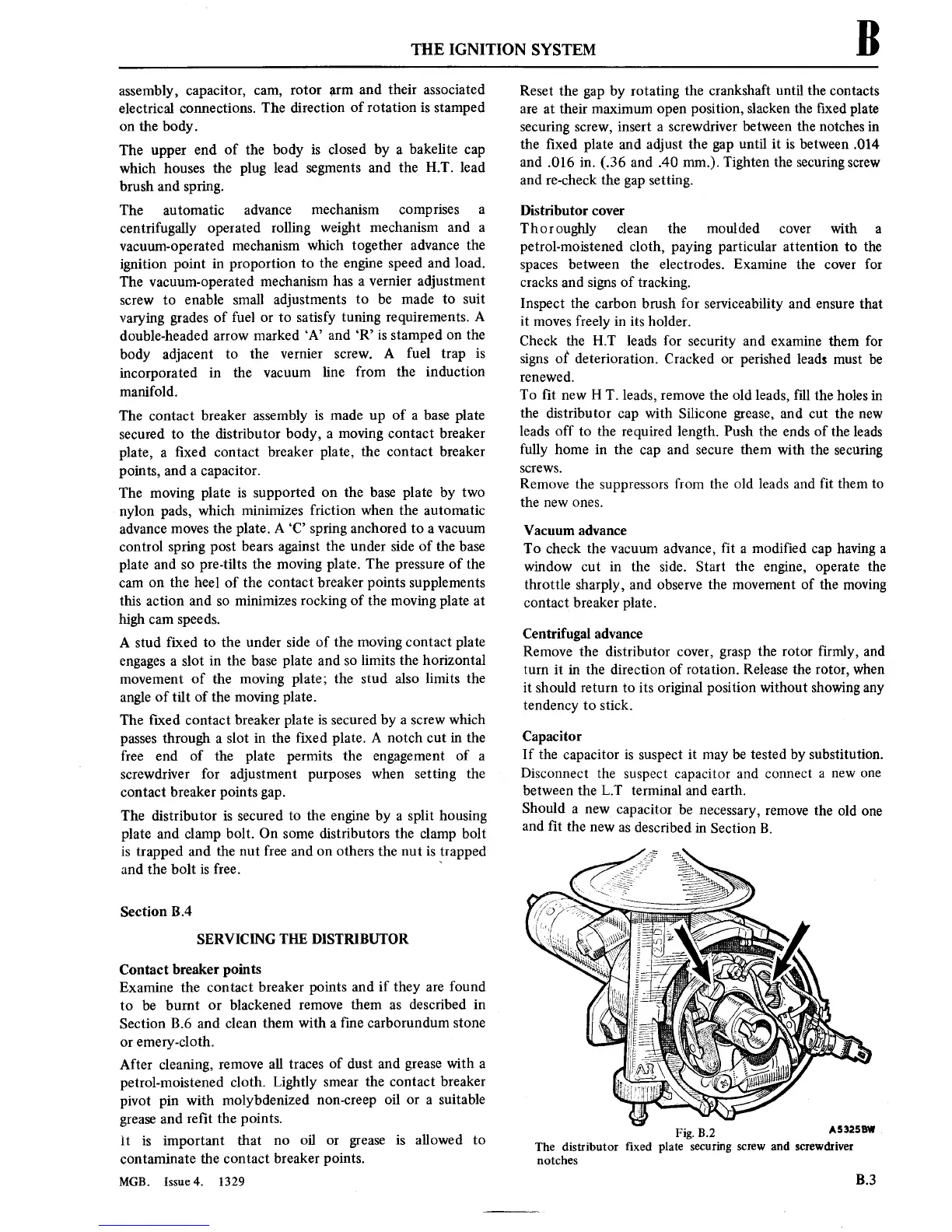

Reset

the

gap

by

rotating

the

crankshaft

until

the

contacts

are

at

their

maximum

open

position,

slacken the ■xed plate

securing

screw,

insert

a

screwdriver between the notches

in

the ■xed plate and adjust

the

gap

until

it is

between

.014

and

.016

in.

(.36

and

.40

mm.).

Tighten

the

securing

screw

and

re-check the

gap

setting.

Distributor

cover

Thoroughly clean the moulded

cover

with

a

petrol-moistened cloth,

paying

particular

attention

to

the

spaces

between

the

electrodes. Examine

the

cover

for

cracks and

signs

of

tracking.

Inspect

the carbon brush for

serviceability

and

ensure

that

it

moves

freely

in its

holder.

Check

the HT leads

for

security

and

examine

them

for

signs

of

deterioration.

Cracked

or

perished leads

must

be

renewed.

To

■t

new

H T. leads,

remove

the old leads, fill

the holes

in

the

distributor

cap

with Silicone

grease,

and

cut

the

new

leads off

to

the required length. Push the

ends

of the leads

fully home

in

the

cap

and

secure

them with the

securing

screws.

Remove the

suppressors

from

the old

leads and

fit them

to

the

new ones.

Vacuum

advance

To

check

the

vacuum

advance,

■t

a

modified

cap

having

a

window

cut

in

the side.

Start

the

engine,

operate

the

throttle sharply, and observe the

movement

of

the

moving

contact

breaker plate.

Centrifugal advance

Remove

the distributor

cover,

grasp

the

rotor

firmly, and

turn

it in

the direction

of

rotation.

Release the

rotor,

when

it

should

return

to

its

original

position

without showing

any

tendency

to

stick.

Capacitor

If the

capacitor is

suspect

it

may

be tested by substitution.

Disconnect the

suspect

capacitor

and

connect

a

new

one

between the LT terminal and

earth.

Should

a new

capacitor

be

necessary,

remove

the

old

one

and ■t

the

new

as

described

in Section B.

A5325“

Fig. 3.2

The

distributor ■xed

plate securing

screw

and screwdriver

notches

B.3

Loading...

Loading...