THE

IGNITION SYSTEM

Contact

breaker gap—Checking—Adjusting

13.

14.

15.

16.

17.

18.

19.

Turn the crankshaft until the heel

of the

contact

point

is

on

the highest

point

of

any

one

of

the

cam

lobes.

Check the

contact

gap;

it

should be 0.014

to

0.016

in.

(0.35

to

0.40 mm).

Adjust the

gap;

to

adjust

insert

a

screwdriver

in

the

slot

in

the

contact

breaker

plate

and

lever

against

the

pip

or

cutout

provided

on

the base

plate.

Tighten the

securing

screw.

Turn

the crankshaft

until

the heel of the

contact

is

on

the highest

point

of

and

alternative

cam

lobe.

Re-check the

contact

gap.

Repeat 17 and 18 for each

remaining

cam

lobe.

Distributor cap—checking

20.

21.

22.

23.

24.

Unclip

and

remove

the distributor

cap.

Remove

the

rotor

arm.

Using

a

clean, nap-free

cloth,

wipe

the

rotor

arm

and

the

inside

of the

distributor

cap.

Examine the

cap

and

arm

for

cracks

and

signs

of

electrical tracking.

Renew

if

necessary.

'

Check the

condition and

operation

of the

carbon

brush. Re■t the distributor

cap.

Distributor dwell angle

25.

26.

27.

Using

suitable

equipment,

check the

distributor dwell

angle.

Readjust the

contact

breaker

gap

to

obtain

the

correct

dwell angle

as

follows:

To

increase

the dwell angle,

reduce

the

contact

gap.

To reduce the

dwell

angle,

increase

the

contact

breaker

gap.

Re-check the

ignition timing, and adjust if

necessary.

Section

B.l6

DISTRIBUTOR—Lucas

type

45D4

A

q

1%.-

Removing

1. Disconnect the battery.

2. Remove the distributor

cap.

3. Rotate

the

crankshaft

until

the

groove

in

the

crankshaft pulley

lines

up

with

the

static ignition

point

on

the

timing indicator

(see

‘ENGINE

TUNING

DATA’)

and

at

the

same

time

the

distributor

rotor

arm

is

in

the ■ring

position

for

No. l sparking plug.

4.

Disconnect the low

tension

lead

from

the

wiring

harness.

5.

Disconnect

the

vacuum

pipe

from

the

distributor

vacuum

advance

unit.

6.

Remove

the

two

screws

securing

the

distributor clamp

plate

to

the cylinder

block.

7. Withdraw the distributor from

the

engine.

MGB.

Issue1.

89961

w■avewwr

3NC1042c

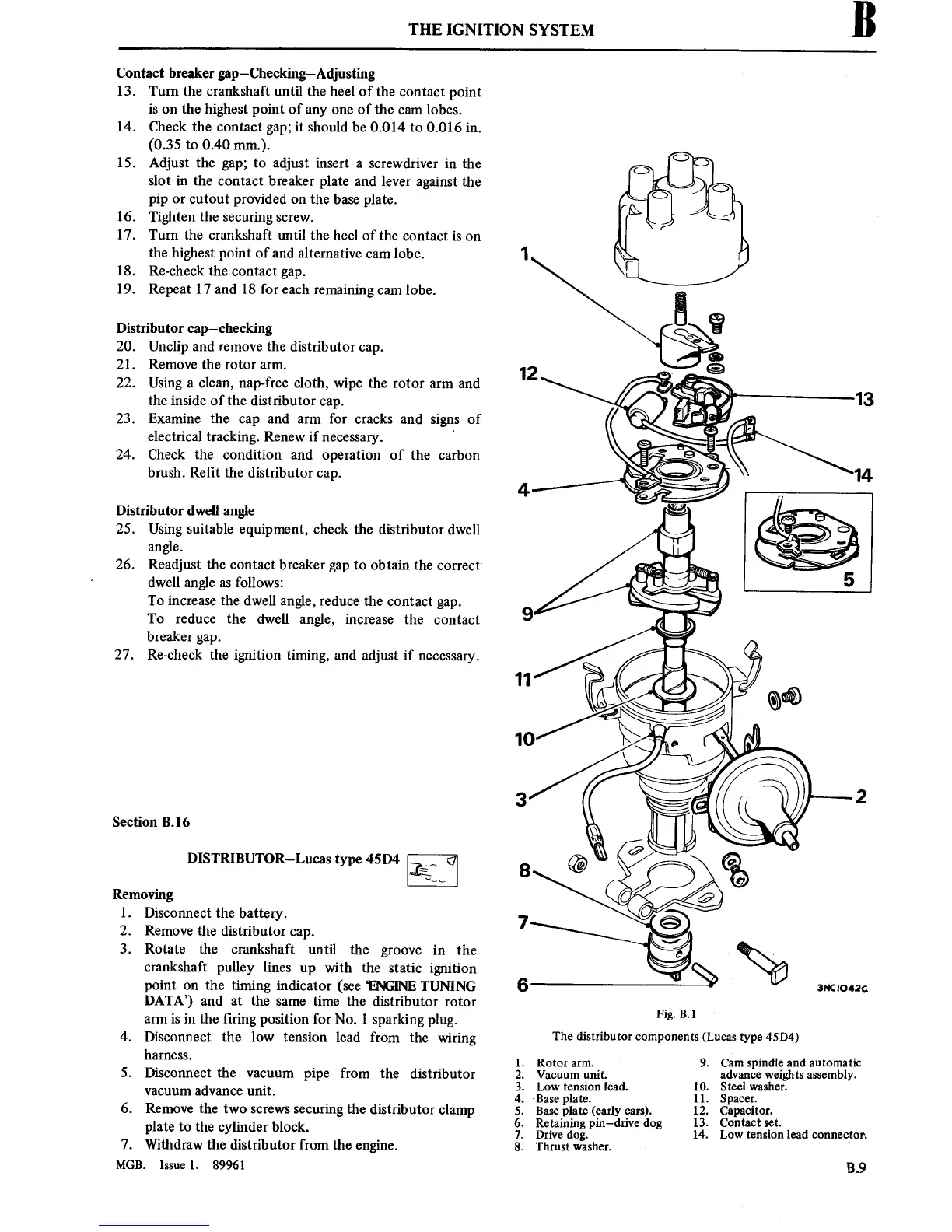

Fig. 13.1

The distributor

components

(Lucas

type

45D4)

Rotor

arm.

9.

Cam

spindleand automatic

Vacuum

unit. advance

weightsassembly.

Low

tension lead. 10.

Steelwasher.

Base

plate. 11. Spacer.

Base

plate (early cars).

12.

Capacrtor.

Retaining

pin—drivedog

13.

Contact

set.

Drive

dog.

14.

Low

tension lead

connector.

Thrust

washer.

B.9

Loading...

Loading...