K

THE

FRONT

SUSPENSION

:u

.

'

8.

Extract the split

pin

from

the

swivel

axle and

remove

the

nut,

upper

trunnion suspension

link, steel and

bronze

thrust washers,

swivel

pin,

and dust

covers

and

spring.

From the

swivel

pin

remove

the

cork washer.

Examination

Wash

all

parts

and

thoroughly dry them with

a

non-■uffy

cloth. Examine all

parts

for

wear or

damage,

paying

particular

attention

to

the swivel

pins,

lower

fulcrum

pins,

and all bushes. Check

the

pins

for ovality. Worn

or

suspect

pins

or

bushes

must

be renewed.

Assembling

and replacing

Reverse

the

dismantling

sequence

to

reassemble the

ax1es,

and,

if

necessary,

renew

the thrust

washers by

selective

assembly

to

produce

a

condition

that will

permit

the swivel

axle

to

rotate

freely

on

the

pin

with

a

minimum

amount

of

end-play. The

maximum

permissible

end-play

is

.002

in.

(.05 mm.).

The

thrust

washers

are

available

in

the

following

sizes:

.052

to

.057

in.

(1.32

to

1.44

mm),

.058

to

.063

in.

(1.47

to

1.60

mm.),

.064

to

.069

in.

(1.62

to

1.75

mm.).

After assembly

reverse

the removal

sequence

to

re■t

the

assembly

to

the hub.

a

Section K.5

REMOVING AND REFITTING BUSHES

Swivel pin bush

'

1.

Press

out

the old bushand

ensure

that the lubrication

“

channels

are

clean and

free

from

obstruction.

'

0

2.

Position

the

new

bush with

:the

split

in

the bush

adjacent

to

the

outef‘face

of'fhe

base. This will

ensure

that the

grease

channel

in

the .bush

is in

line with the

.

chahnel

in

the

pin.

'

'

Al562

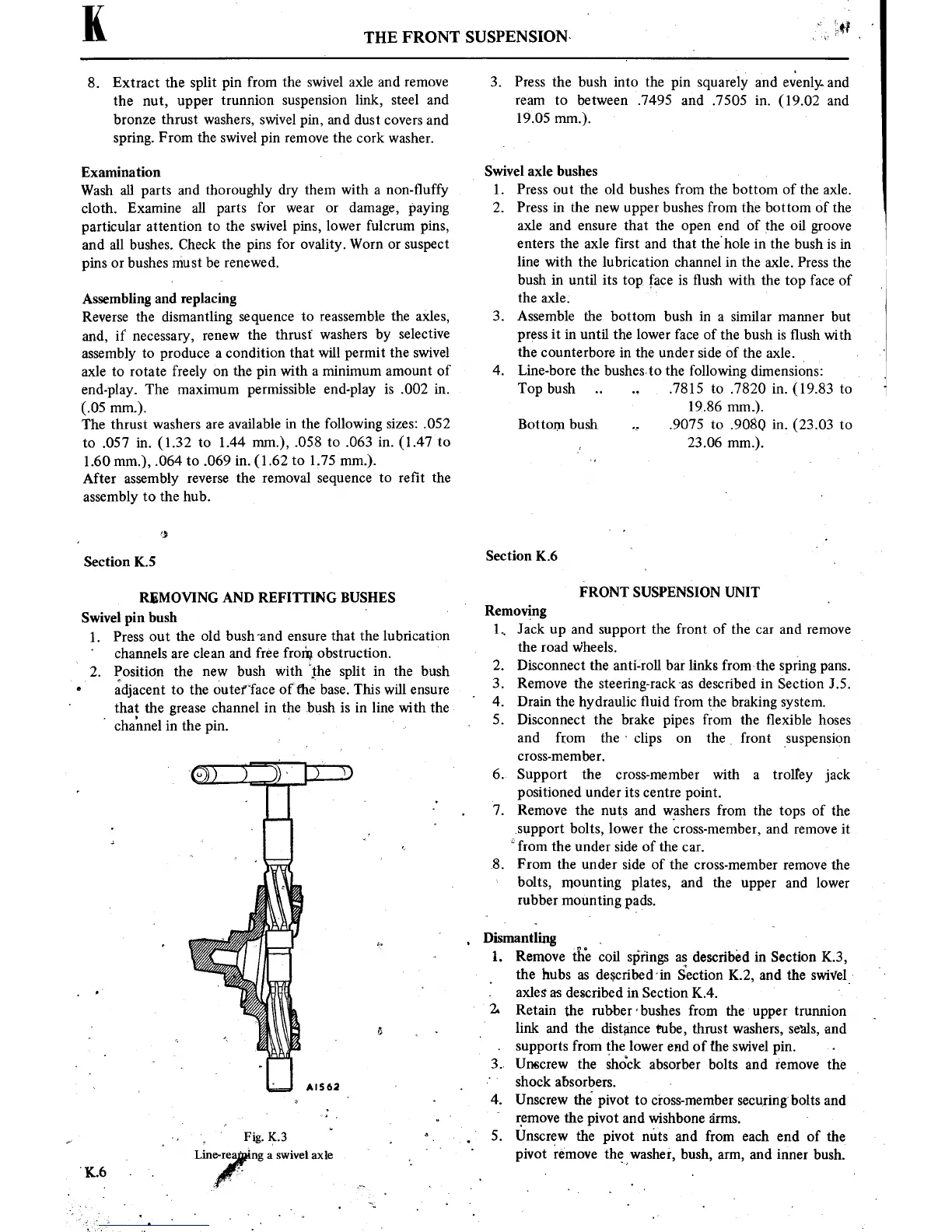

Fig. k3

"

,

°.

~

.

_

“

Line-rea

ingaswivel

axle

K.6

.

.

,

3.

Press the bush

into

the

pin

squarely

and

evenly.

and

ream

to

between .7495 and

.7505

in.

(19.02

and

19.05

m.).

V

Swivel axle bushes

1.

Press

out

the old bushes

from

the bottom of the axle.

2.

Press

in

the

new

upper

bushes from the

bottom

Of

the

axle and

ensure

that the

open

end of the oil

groove

enters

the axle first

and that

thehole

in

the bush

is in

line with the

lubrication channel

in

the

axle. Press the

bush

in

until

its

top,

face

is

■ush

with the

top

face of

the

axle. '

3. Assemble the

bottom

bush

in

a

similar

manner

but

press

it in

until the lower face of

the bush

is

flush

with

the

counterbore

in

the under side of the

axle.

‘

4. Line—bore the bushesto the following

dimensions:

Top bush

.7815

to

.7820

in.

(19.83

to

‘

19.86

mm.).

Bottom

bush

.9075

to

.9080

in.

(23.03

to

23.06

mm.).

Section

K.6

FRONT

SUSPENSION UNIT

Removing

1.,

Jack

up

and

support

the front of the

car

and

remove

the road w'heels.

‘

2. Disconnect the anti-roll bar links fromthe

spring

pans.

3.

Remove the

steering-rackas described

in

Section J.5.

4.

Drain the hydraulic ■uid from

the braking

system.

5. Disconnect the brake

pipes

from the ■exible

hoses

and from the

‘

clips

on

the

,

front

suspension

cross-member.

v

6. Support the

cross-member with

a

trolley

jack

positioned

under

its

centre

point.

‘7.

Remove the

nuts

and washers from the

tops

of the

,support

bolts, lower the

cross-member, and

remove

it

from

the

under Side

of

the

car.

.8. From the

under side of the

cross-member

remove

the

bolts,

mounting

plates, and the

upper

and lower

rubber

moUnting

pads.

,

Dismantling

1.

Remove

the

coil

Springs

as

described

in

Section

K3,

the

hubs

as

describedin

Section K2, and the SWiVel-

axles

as

described

in

Section

K.4.

'

'

'

2s

Retain the

rubbercbushes from the

upper

trunnion

link

and the

distance

tube,

thrust washers, seals,

and

supports

from

the lower end of the swivel

pin.

3.. Unscrew the

shdck

absorber bolts and remove the

t

'

‘

shock

absorbers.

-

4. Unscrew

the

pivot

to

cross-member

securing

bolts

and

‘

‘

remove

the

pivot

and wishbone

arms.

*

5. Unscrew the

pivot

nuts

and

from

each end of the

pivot

remove

the■washer, bush,

arm,

and

inner

bush.

Loading...

Loading...