THE BRAKING SYSTEM

M

Removing

the calliper

pistons

Unscrew

and

remove

the

two

bolts

securing

the calliper

to

the front hub and withdraw the calliper from the disc and

hub. Do

not

remove

the

rubber hose, and

support

the

calliper

to

avoid

straining

the hose.

Remove

the friction

pads and

clean

the outside

of

the calliper, making

sure

that

all dirt and

traces

of cleaning ■uid

are

completely

removed.

Clamp the

piston

in

the

mounting

half of the calliper

and

gently

apply

the

foot brake. This

operation

will

force the

piston in

the

rim

half of the calliper

to

move

outwards.

Continue with gentle

pressure on

the foot pedal

until

the

piston

has

emerged

suf■ciently for

it

to

be removed by

hand.

Have

a

clean

receptacle ready

to

catch the ■uid

as

the

piston is

removed.

With

a

suitable blunt-nosed tool

remove

the

■uid

seal

from

its

groove

in

the bore

of the

calliper, taking

great

care

not

to

damage the bore

of the calliper

or

the seal

retaining

groove.

The dust

seal

retainer

can

be removed

by

inserting

a

screwdriver between the

retainer

and

the seal and gently

prising

the

retainer

from the mouth of the calliper bore.

The rubber seal

can

then

be detached.

Remove

the clamp from

the mounting-half

piston.

To

remove

the

mounting-half

piston

from the calliper

it is

necessary

■rst

to

re■t

the

rim-half

piston,

and

thereafter

the procedure

is

as

previously

detailed.

When cleaning

out

the

calliper

it is

essential

that

only

methylated

spirit

or

Lockheed Brake

Fluid be used

as a

cleaning medium.

Other

types

of

cleaning

■uid

may

damage

the internal rubber

seal between

the

two

halves of the

calliper.

\\\\\\:\\\

\‘31

mMW

A 607

7

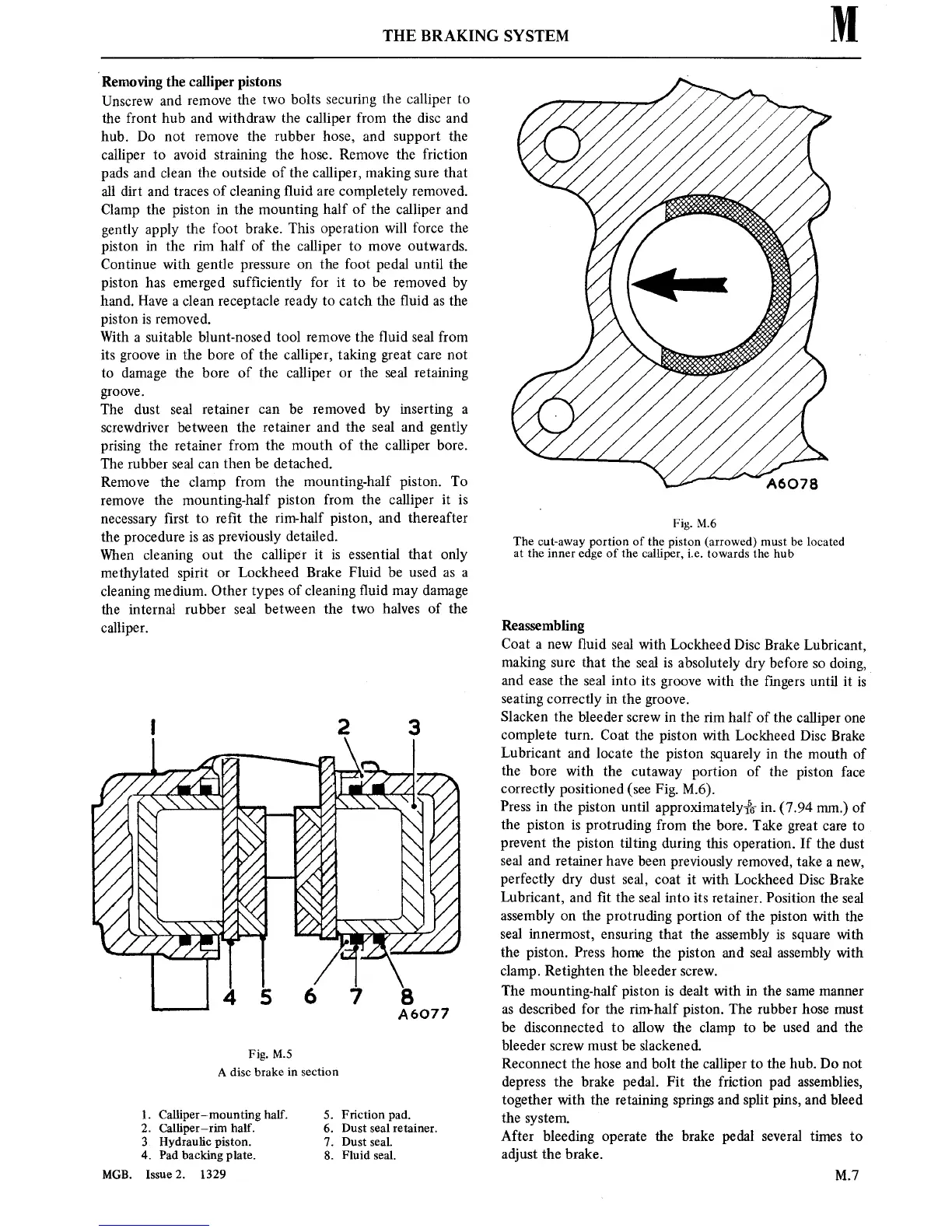

Fig. M.5

A

disc

brake in section

1. Calliper—mounting half.

5.

Friction

pad.

2. Calliper—rirnhalf. 6. Dust sealretainer.

3 Hydraulic piston.

7. Dust seal.

4. Padbacking

plate. 8.

Fluid

seal.

MGB. IssueZ.

1329

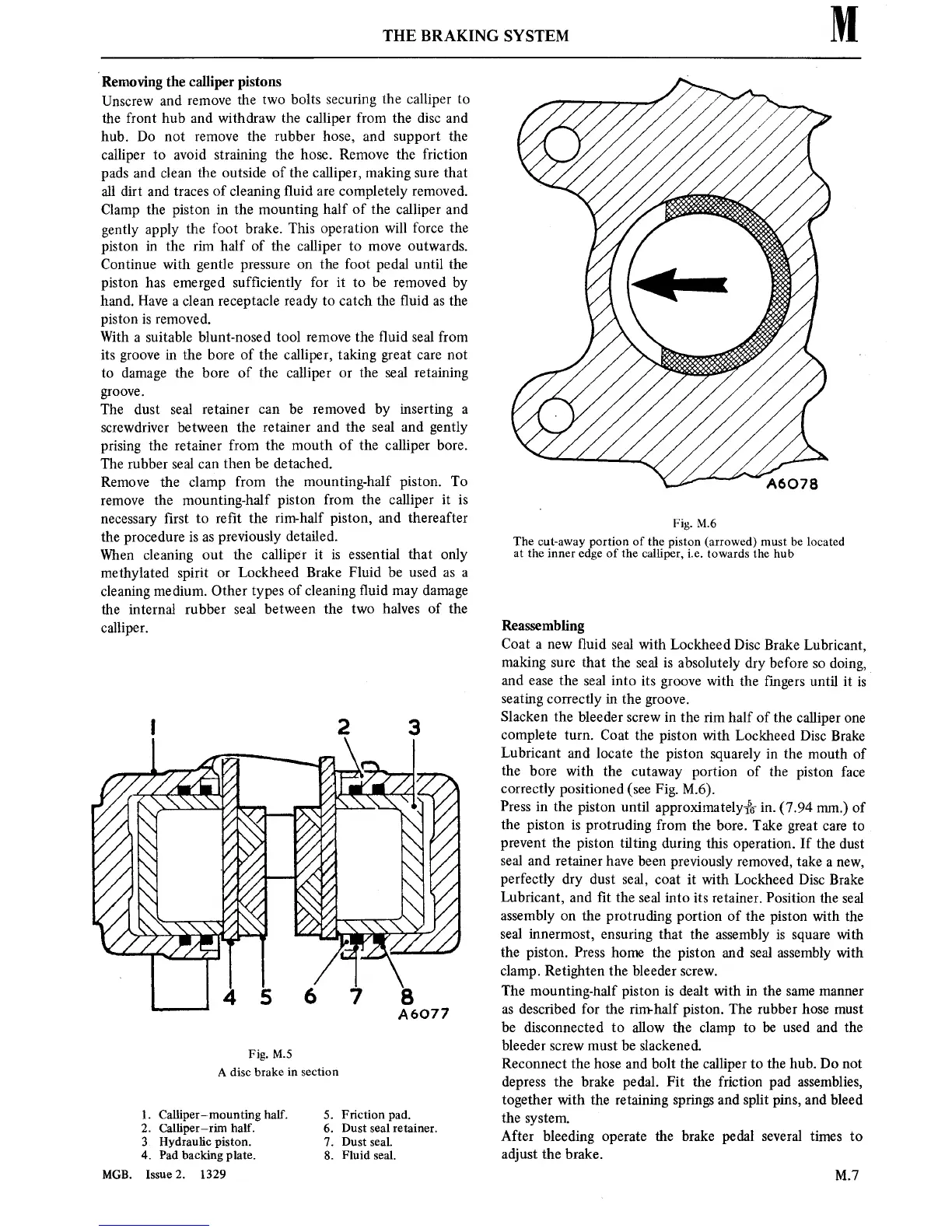

Fig. M.6

The

cut-away

portion of the

piston (arrowed)

must

be located

at

the

inner

edgeof the calliper, i.e.

towards the hub

Reassembling

Coat

a new

■uid

seal with

Lockheed

Disc Brake Lubricant,

making

sure

that the seal

is

absolutely dry before

so

doing,

and

ease

the seal

into its

groove

with

the

■ngers

until

it is

seating

correctly

in

the

groove.

Slacken the

bleeder

screw

in

the

rim

half of the calliper

one

complete

turn.

Coat the

piston

with

Lockheed

Disc Brake

Lubricant

and locate the

piston

squarely

in

the mouth of

the bore

with the

cutaway

portion

of the

piston

face

correctly

positioned

(see

Fig.

M.6).

Press

in

the

piston

until

approximately—1%

in.

(7.94

mm.)

of

the

piston

is

protruding from the bore.

Take

great

care

to

prevent

the

piston

tilting during this

operation.

If

the dust

seal

and

retainer

have

been previously

removed, take

a

new,

perfectly dry

dust seal,

coat

it

with Lockheed

Disc Brake

Lubricant,

and ■t the

seal

into its retainer.

Position the seal

assembly

on

the protruding

portion

of the

piston

with the

seal

innermost,

ensuring

that the

assembly

is

square

with

the

piston.

Press home the

piston

and seal assembly with

clamp.

Retighten the bleeder

screw.

The mounting-half

piston is

dealt with

in

the

same manner

as

described for the rim-half

piston.

The rubber hose

must

be disconnected

to

allow the clamp

to

be used

and the

bleeder

screw

must

be slackened.

Reconnect

the hose and bolt the calliper

to

the

hub.

Do

not

depress the brake pedal. Fit

the friction pad assemblies,

together with the

retaining springs

and split

pins,

and

bleed

the

system.

After bleeding

operate

the brake pedal several

times

to

adjust the brake.

M.7

Loading...

Loading...