THE

ENGINE

A

The

upper

ends

of the choke

return

springs

are

fitted

to

the

cam

levers

of

the forward

and

rear

carburetters

and the

lower

ends

to

clips

on

the bottom

of the heat

shield.

To

remove

the accelerator control take

off the

air

cleaners

as

detailed

in

Section

D, release

the

inner

cable

from

the

spindle and

lever assembly and withdraw

the

inner

cable

from the

outer

cable

at

the pedal end.

Release

the

accelerator

cable

clip

in

the

engine

compartment

and

remove

the

outer

cable.

Unscrew

the pedal assembly

fulcrum

bolt from the pedal

bracket

and

remove

the pedal,

bush, and distance

piece.

Replacement

is

a

reversal

of the removal

sequence.

After replacement

ensure

that the control

is

adjusted

correctly

as

detailed

in

Section

D.

To

remove

the choke control release

the

inner

cable

from

the

pin

on

the choke control bracket and

retain

the cable

abutment.

Free

the

grommet

from

the bulkhead.

From the

rear

of the

fascia

panel

unscrew

the

securing

nut

and withdraw

the assembly

from the fascia.

Replacement is

a

reversal

of the

removal

sequence.

After replacing

the accelerator

and

choke controls

ensure

that

they

are

correctly

adjusted

as

detailed

in

Section

D.

Section

A.23

EXHAUST

SYSTEM

The

exhaust

system

is

made

up

of

a

front

pipe

and junction

assembly,

a

front intermediate

pipe,

a

front silencer,

a

rear

intermediate

pipe,

and

a

rear

silencer

and tail

pipe.

The

assembly

is

welded together.

The

front

pipe

and

junction

assembly

mate

with the

exhaust

manifold

ports;

joint

washers

are

■tted

to

each

pipe.

The front

intermediate

pipe is

supported

by

a

clip

which

is

attached

to

a

strap

and

bracket. The bracket

is

bolted

to

the

lower

■ange of the gearbox.

A

rubber

mounting

bolted

to

the

rear

frame

member

supports

a

bushed housing

to

which

is

attached

the front

silencer mounting

bracket.

A

second rubber

mounting

bolted

to

the

rear

frame

embodies

a

split

clamp that

secures

the

tail

pipe.

To

remove

the

exhaust assembly

remove

the

six

nuts

from

the

manifold

port

studs,

allow the

twin pipes

to

drop,

and

retain

the joint

washers.

Loosen

the

rear

mounting

tail

pipe

securing

bolt,

remove

the front

silencer

support

clip bolt, and

draw the

assembly

forward and

downward.

To

re■t the assembly

reverse

the removal

sequence

but

leave the

front

silencer

and tail

pipe

securing

bolts slack

until

the

twin

down

pipes

and

joint

washers have

been

■tted and

tightened. Tighten

the silencer

clip

bolt

and

■nally the

split

clamp bolt

on

the tail

pipe.

MGB.

Issue

9. 80619

*

'-

\

/:

:

r

C

a

\t

,

1

\\

1

I

\

;

\

’HnuH‘

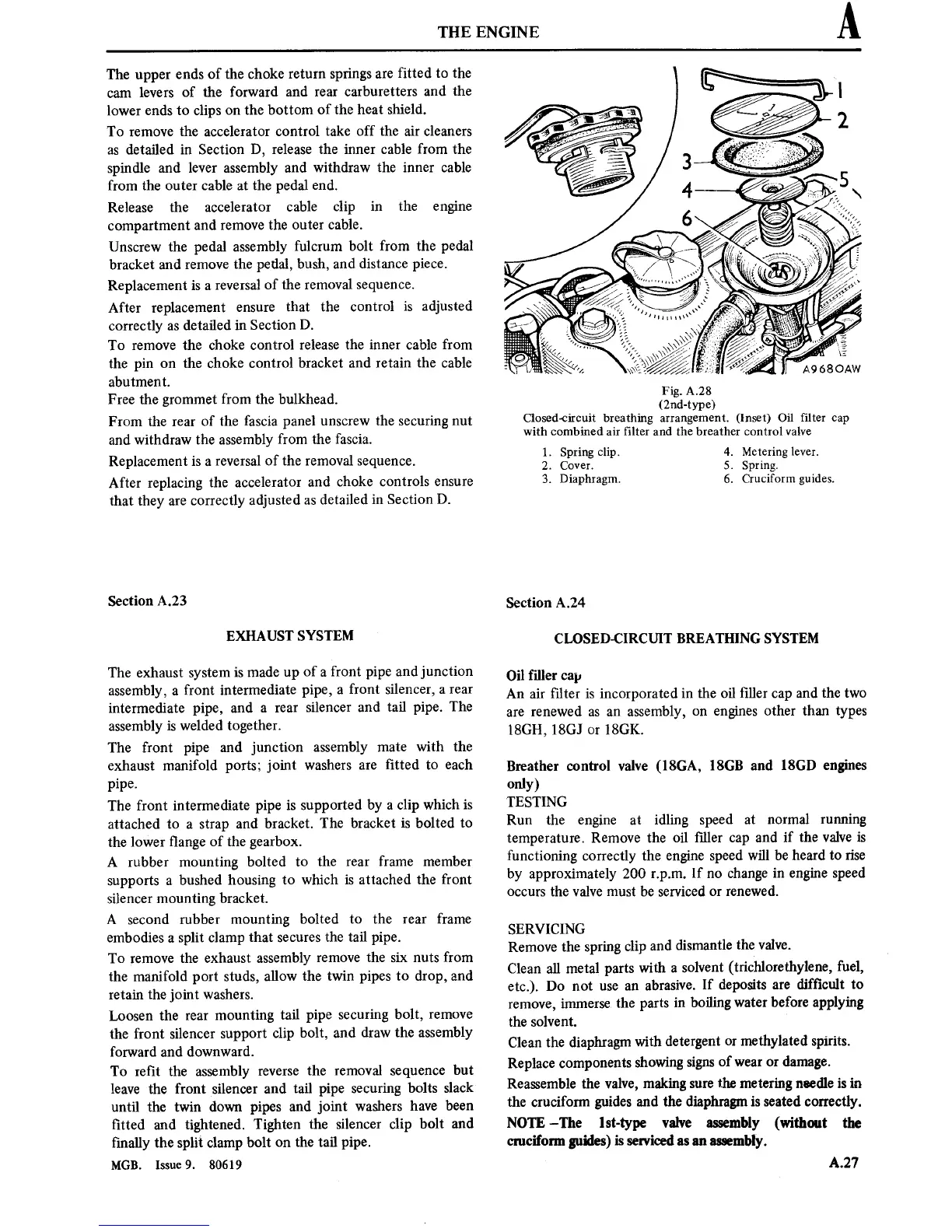

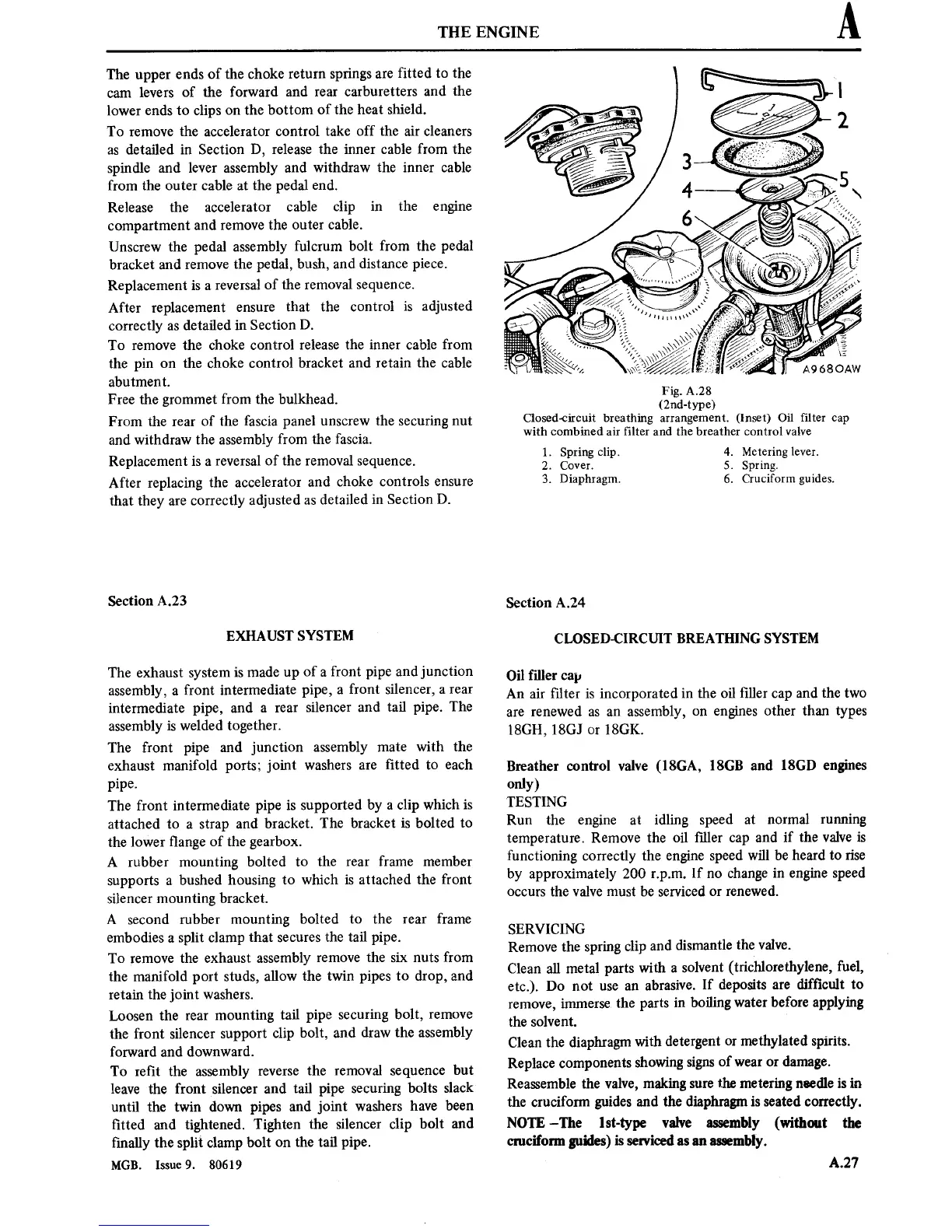

Fig.

A28

(2nd-type)

Closed-circuit breathing

arrangement.

(Inset) Oil

■lter

cap

with combined

air

■lter and the breather control valve

1.

Spring clip.

2. Cover.

3. Diaphragm.

4.

Metering lever.

5. Spring.

6.

Cruciform guides.

Section

A.24

CLOSED-CIRCUIT BREATHING SYSTEM

Oil filler

cap

An air

■lter

is

incorporated

in

the oil

■ller

cap

and the

two

are

renewed

as an

assembly,

on

engines

other than

types

18GH, 18G]

or

18GK.

Breather

control valve (18GA, 18GB

and 18GB engines

only)

TESTING

Run

the

engine

at

idling

speed

at

normal

running

temperature.

Remove

the oil

■ller

cap

and

if the valve

is

functioning correctly the

engine

speed will be

heard

to

rise

by approximately 200

rpm.

If

no

change

in engine

speed

occurs

the valve

must

be serviced

or

renewed.

SERVICING

Remove

the

spring

clip

and

dismantle the valve.

Clean

all

metal

parts

with

a

solvent

(trichlorethylene,

fuel,

etc.).

Do

not

use an

abrasive.

If deposits

are

dif■cult

to

remove,

immerse

the

parts

in

boiling

water

before applying

the solvent.

Clean

the

diaphragm

with detergent

or

methylated

spirits.

Replace

components

showing

signs

of

wear or

damage.

Reassemble the

valve,

making

sure

the

metering

needle

is in

the

cruciform guides and

the

diaphragm

is

seated correctly.

NOTE

—The

lst-type valve assembly (without

the

cruciform guides)

is

serviced

as an

assembly.

A.27

Loading...

Loading...