N

THE

ELECTRICAL

SYSTEM

16.

Unscrew

the

two

brush moulding securing

screws.

17.

Slacken

the

recti■er

pack retaining

nuts

and

withdraw

the brush

moulding

and

recti■er pack.

BRUSHES

18.

Check

the

brushes for

wear

by measuring

the

length of

brush protruding

beyond the

brushbox

moulding.

If

the

length

protruding

is

.2

in.

(5

mm.)

or

less

the

brush

must

be

renewed.

19.

Check

that

the brushes

move

freely

in

their holders.

If

a

brush shows

a

tendency

to

stick,

clean

it

with

a

petrol

(gasoline) moistened cloth

or,

if

necessary

polish the sides

of the

brush with

a

fine ■le.

20.

Check the

brush

spring

pressure

using

a

push-type

spring

gauge.

The

gauge

should

register

7

to

10

oz.

(198

to

283

gm.)

when

the

brush

is

pushed back until

its

face

is

■ush with

the housing.

If

the

gauge

reading

is

outside

the limits

given,

renew

the

brush assembly.

SLIP-RINGS

21.

Clean

the

surfaces

of

the slip-rings

using

a

petrol

(gasoline) moistened cloth.

22. Inspect

the slip-ring

surfaces for

signs

of burning;

remove

burn

marks

using

very

■ne sand-paper. On

no

account

must

emery-cloth

or

similar abrasives

be used

or

any

attempt

made

to

machine

the slip-rings.

ROTOR

23.

Connect

an

ohmmeter

or

a

12-volt

battery

and

an

ammeter

to

the slip-rings. An

ohmmeter

reading of 4.3

ohms

or an

ammeter

reading

of

3

amps.

should be

recorded.

24.

Using

a

llO-volt A.C’

supply and

a

15-watt

test

lamp,

test

for insulation between

one

of the slip-rings and

one

of the

rotor

poles.

If the

test

lamp

lights the

rotor

must

be

renewed.

STATOR

25.

Connnect

a

12-volt battery

and

a

36-watt

test

lamp

to

two

of

the

stator

connections.

Repeat

the

test

replacing

one

of

the

two

stator

connections

with the

third. If the

test

lamp

fails

to

light

in

either

of

the

tests

the

stator

must

be

renewed.

26.

Using

a

llO-volt A.C.

supply and

a

lS-watt

test

lamp,

test

for insulation between

any one

of

the

three

stator

connections

and the

stator

laminations.

If the

test

lamp lights,

the

stator must

be

renewed.

DIODES

27.

Connect

a

l2-volt

battery

and l.5-watt

test

lamp

in

turn to

each of the

nine

diode

pins

and

its

corresponding heat

sink

on

the recti■er pack, then

reverse

the

connections.

The lamp should light with

the

current

flowing

in

one

direction

only. If the

lamp

lights

in

both directions

or

fails

to

light

in

either, the

recti■er pack

must

be renewed.

N30

IMPORTANT.—See

notes

on

soldering the

diodes

givenin2.

DISMANTLING

28.

Carry

out

the

operations

detailed

in

14

to

17.

29. Remove

the three

through-bolts.

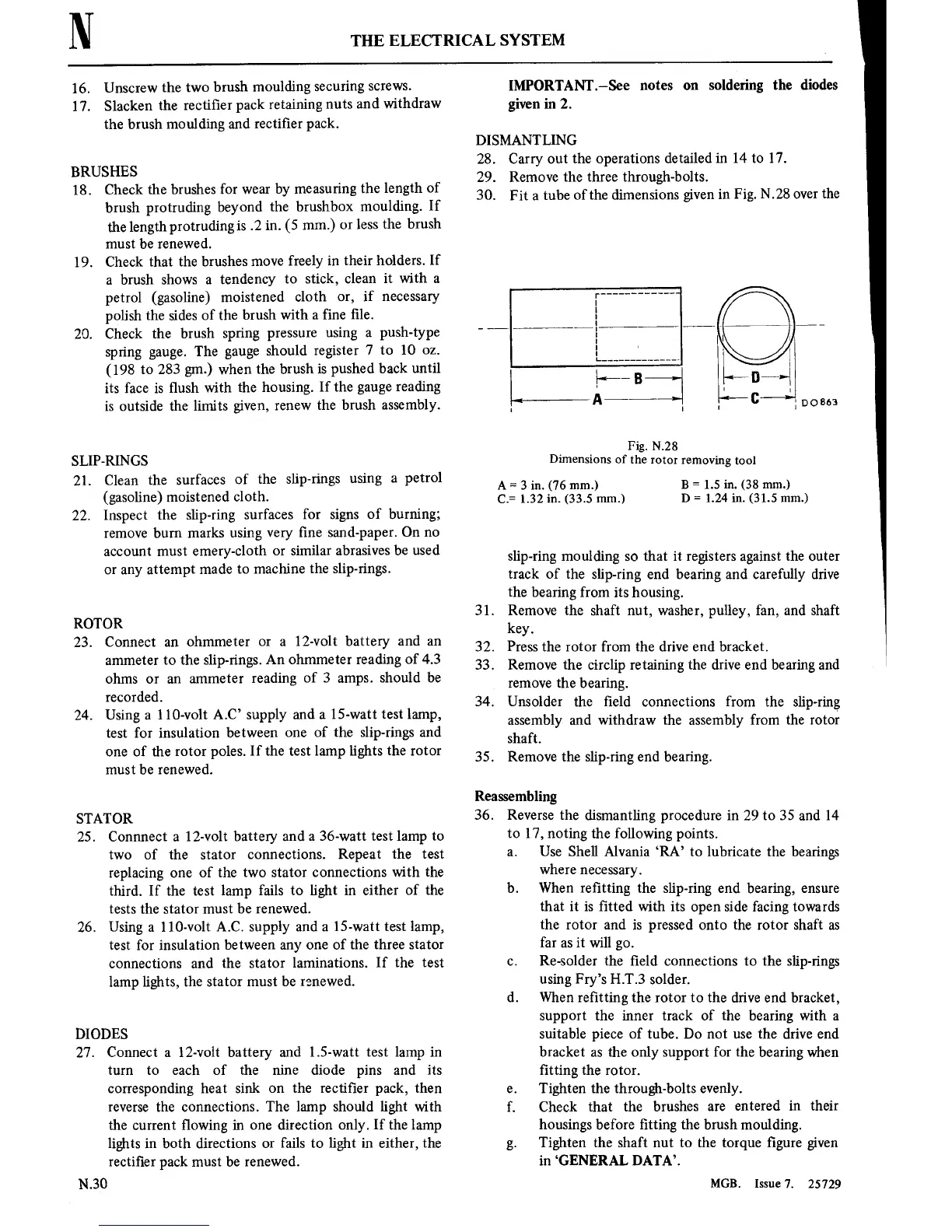

30.

Fit

a

tube

of the dimensions given

in

Fig. N.28

over

the

1+4

©

l<——B

A

,Doaea

Fig. N.28

Dimensions

of

the

rotor

removing

tool

=

B

=

1.5

in. (38 mm.)

.=

.32 in. (33.5 mm.)

D

=

1.24

in.

(31.5 mm.)

slip-ring moulding

so

that

it

registers

against

the

outer

track of the slip-ring end bearing

and

carefully drive

the

hearing from

its

housing.

31. Remove

the shaft

nut,

washer,

pulley,

fan,

and shaft

key.

32.

Press the

rotor

from the drive end bracket.

33.

Remove the circlip

retaining

the drive end bearing and

remove

the bearing.

34. Unsolder the ■eld

connections

from the slip-ring

assembly and withdraw the

assembly from the

rotor

shaft.

35.

Remove the slip-ring end bearing.

Reassembling

36. Reverse the dismantling

procedure

in 29

to

35 and 14

to

17,

noting

the following

points.

21.

Use Shell Alvania

‘RA’

to

lubricate

the bearings

where

necessary.

b. When re■tting the

slip-ring end bearing,

ensure

that

it is

■tted

with

its

open

side facing towards

the

rotor

and

is

pressed

onto

the

rotor

shaft

as

far

as

it

will

go.

c.

Re-solder the ■eld

connections

to

the slip-rings

using

Fry’s

H.T.3 solder.

d. When re■tting

the

rotor to

the

drive end

bracket,

support

the

inner

track

of

the bearing with

a

suitable

piece

of

tube. Do

not

use

the drive end

bracket

as

the only

support

for

the

bearing when

■tting

the

rotor.

e.

Tighten the through-bolts

evenly.

f. Check that

the

brushes

are

entered

in

their

housings

before

■tting

the brush moulding.

g.

Tighten the

shaft

nut to

the

torque

■gure

given

in

‘GENERAL DATA’.

MGB.

Issue7. 25729

Loading...

Loading...