THE ENGINE

A

Completely

unscrew

the eight rocker shaft bracket

nuts

and

remove

the rocker assembly, complete with brackets

and

rockers. Withdraw

the eight

push-rods,

storing

them

carefully

so

that they

may

be replaced

in

the

same

positions.

To

dismantle the

rocker

shaft

assembly, first

remove

the

grub

screw

which locates

the

rocker shaft

in

the

rear

rocker

mounting

bracket and

remove

the split

pins,

flat

washers, and

spring

washers from each

end

of

the shaft.

Slide

the

rockers, brackets, and

springs

from the

shaft.

Unscrew the- plug from the front

end

of

the shaft

and clean

out

the oilways.

Reassembly and replacement

is

a

reversal

of

the

above

procedure replacing the rockers and

springs in

their

original

positions

on

the

shaft.

Remember

to

replace the rocker

shaft locating

screw

lock plate.

Replace the

rocker

cover

with the

vent

pipe

to

the front. Check that the

two

cap

nut

rubber

bushes and the rocker

cover

cork gasket

are

undamaged; if they

are

found

to

be

faulty, ■t

new ones or

oil

leaks

may

result.

Refitting rocker bushes

To

remove

and replace

worn

rocker bushes

the

use

of

Service

tool 18G

226

is

recommended; the bushes

and the

rockers

can

be

Very

easily damaged by

using improvised

drifts. Place the rocker

on

the anvil

and drive

out

the

worn

bush.

Place

a

new

bush

on

the driver and

position

the bush

with

the butt

joint

at

the

top

of the

rocker bore and

the

oil

groove

in

the bush

at

the bottom

of the rocker

bore,

as

shown

in

Fig.

A.3

It

will be

necessary

to

drill the oil

holes

in

the bush

to

coincide

with the

oilways

in

the rocker. The

oil

hole

to

the

adjuster

end

can

be

drilled before the bush

is

■tted,

extra

care

being

taken

to

keep the holes

of the

bush

and

rocker

in

line

during the

pressing-in operation.

If the holes

are

drilled after ■tting, the

following

procedure

must

be adopted.

Remove the adjuster

screw

and

use a

.093

in.

(2.36 mm.)

drill

to

drill

out

the

end plug

and

to

continue

the oilway through the

bush. Replug the

end after

this

operation

with

a

rivet

(

Part No.

SC 2436)

and weld the

plug

into position.

The oil hole

in

the

top

of

the rocker

barrel

must

be continued through

the bush

with

a

N0

47

drill,

.0785

in.

(1.98

mm.).

eaag

‘

s©m©n@m@

O O

Q

o

0

100.0

one

080

OQOJ

«t9

-

é

AD1325W

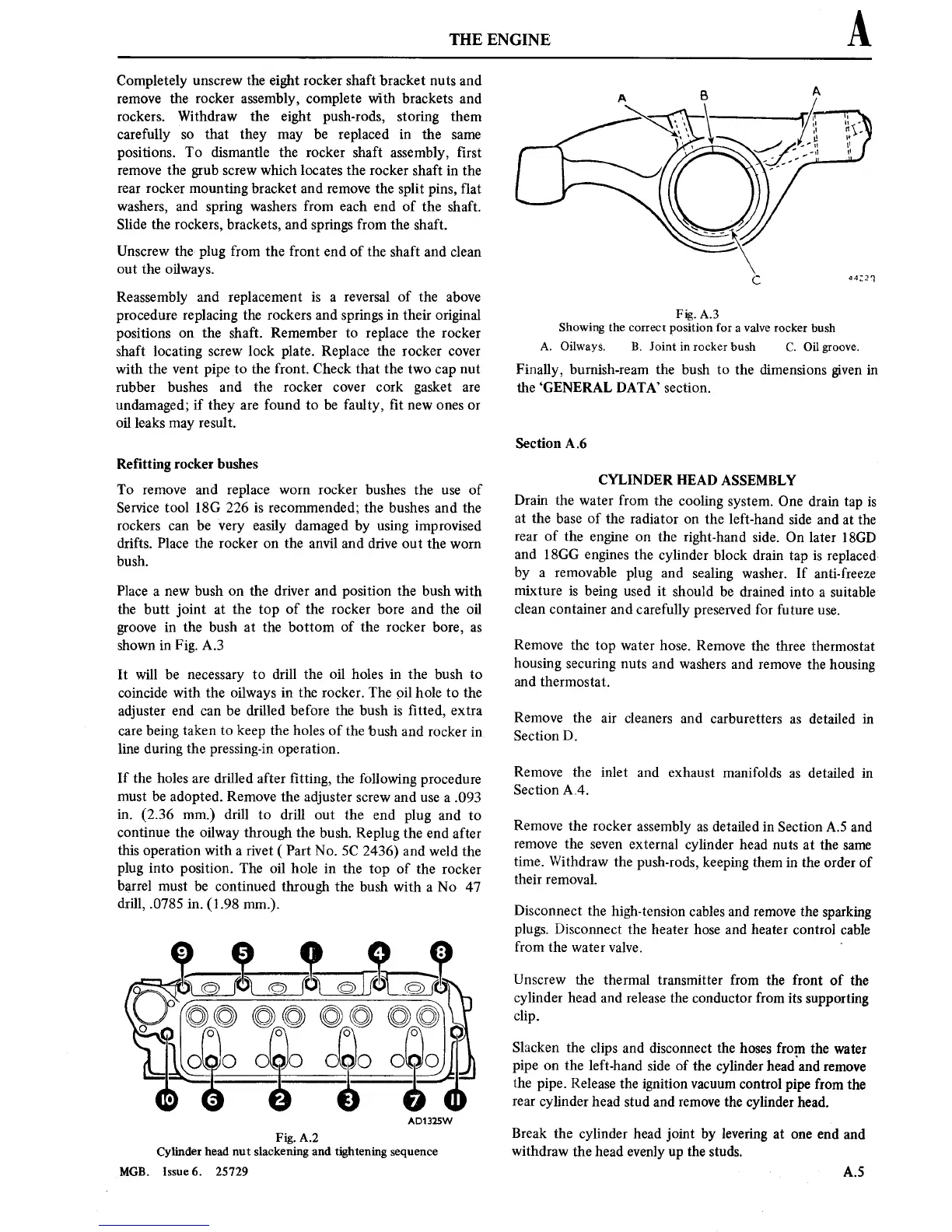

Fig.A.2

Cylinder head

nut

slackening

and tightening

sequence

MGB.

Issue

6. 25729

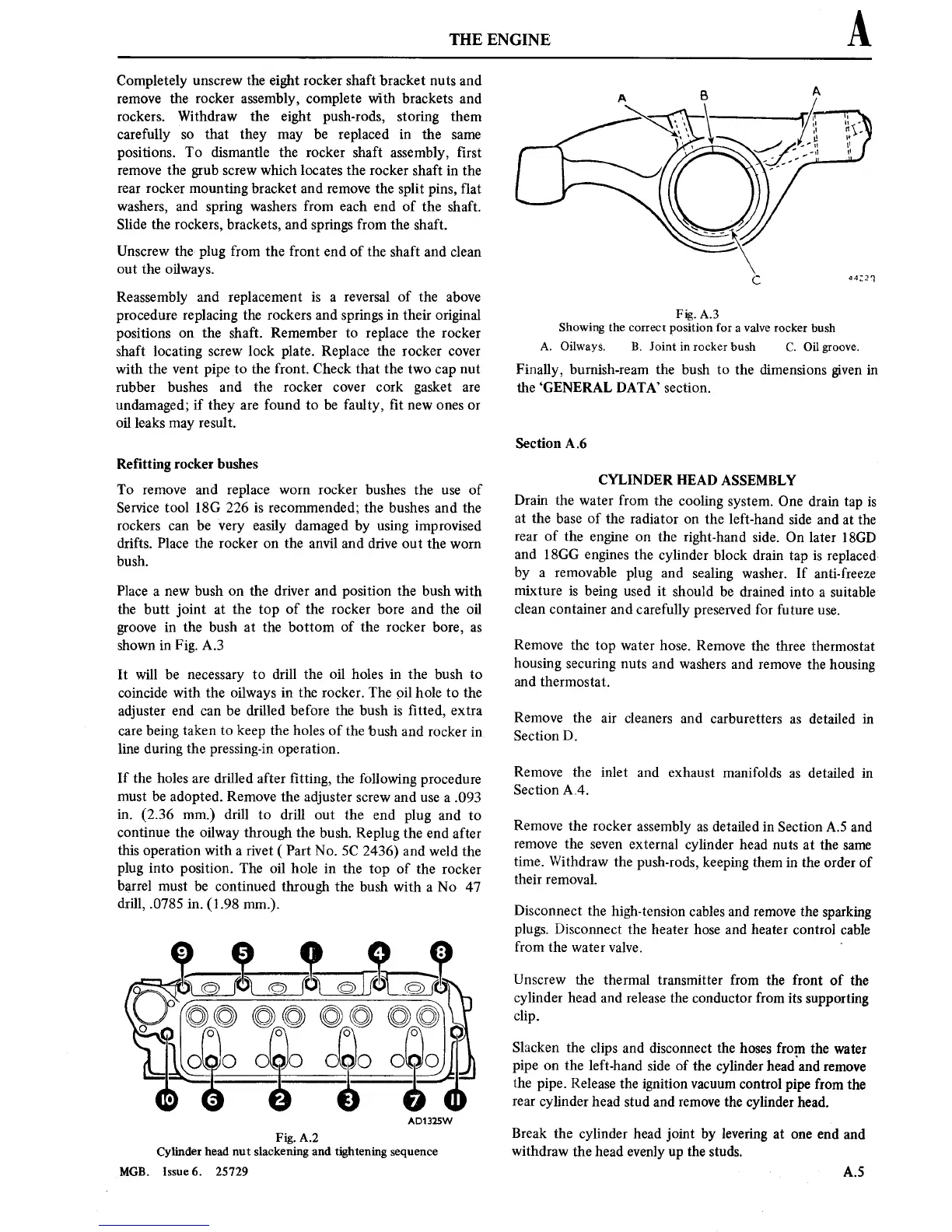

Fig.

A.3

Showing

the

correct

position for

a

valve rocker

bush

C.

Oil

groove.

A.

Oilways.

B. Joint in rocker bush

Finally, burnish-ream the bush

to

the

dimensions

given in

the

‘GENERAL

DATA’

section.

Section

A.6

CYLINDER

HEAD

ASSEMBLY

Drain the

water

from

the cooling

system.

One

drain

tap

is

at

the

base

of the radiator

on

the left-hand

side

and

at

the

rear

of the

engine

on

the right-hand

side. On later 180D

and l8GG

engines

the

cylinder

block drain

tap

is

replaced

by

a

removable

plug and

sealing washer. If anti-freeze

mixture

is

being

used

it

should

be

drained

into

a

suitable

clean

container

and carefully

preserved

for

future

use.

Remove the

top water

hose.

Remove the

three thermostat

housing

securing

nuts

and washers

and

remove

the

housing

and thermostat.

Remove the

air

cleaners

and carburetters

as

detailed

in

Section

D.

Remove the

inlet

and exhaust manifolds

as

detailed

in

Section A.4.

Remove

the rocker

assembly

as

detailed

in Section A5 and

remove

the

seven

external

cylinder head

nuts at

the

same

time.

Withdraw

the push-rods,

keeping them

in

the order

of

their

removal.

Disconnect

the high-tension

cables and

remove

the sparking

plugs. Disconnect

the heater

hose

and

heater

control cable

from the

water

valve.

‘

Unscrew

the

thermal

transmitter

from the front of

the

cylinder head

and release the conductor from

its

supporting

clip.

Slacken

the

clips and disconnect the hoses from

the

water

pipe

on

the left-hand

side

of the

cylinder

head

and

remove

the

pipe.

Release the

ignition

vacuum

control

pipe

from

the

rear

cylinder head

stud and

remove

the

cylinder

head.

Break the

cylinder

head

joint

by levering

at

one

end

and

withdraw

the

head

evenly

up

the studs.

A.5

Loading...

Loading...