THE ELECTRICAL

SYSTEM

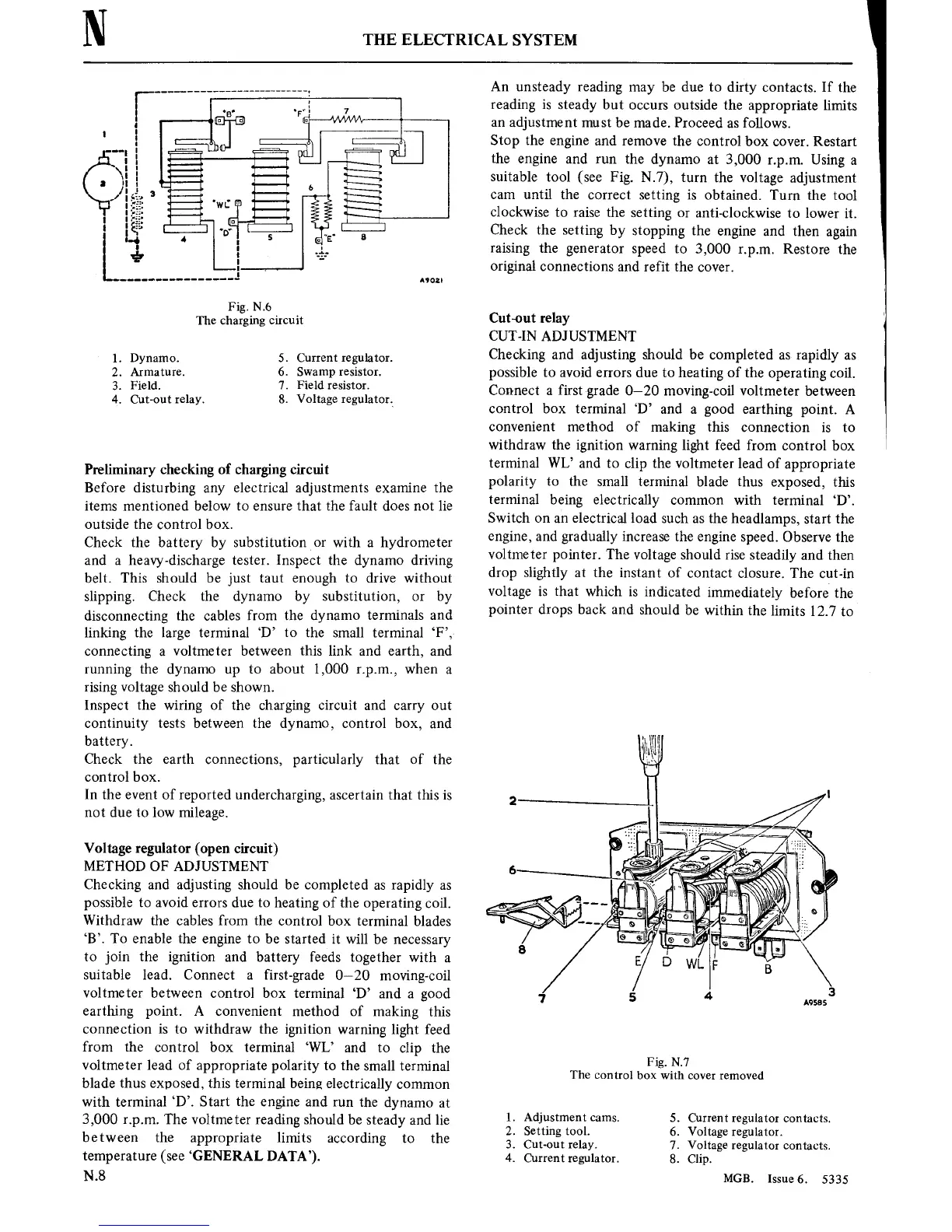

Fig. N13

The charging

circuit

1.

Dynamo. 5. Current regulator.

2.

Armature.

6. Swampresistor.

3.

Field. 7. Field resistor.

4. Cut-out

relay. 8.

Voltage

regulator.

Preliminary checking

of

charging circuit

Before disturbing

any

electrical adjustments

examine

the

items

mentioned

below

to

ensure

that the fault

does

not

lie

outside

the

control

box.

Check the battery by substitutionor with

a

hydrometer

and

a

heavy-discharge

tester.

Inspect

the dynamo driving

belt.

This should be

just

taut

enough

to

drive without

slipping.

Check the

dynamo

by

substitution,

or

by

disconnecting the

cables from the dynamo

terminals and

linking the large terminal ‘D’

to

the small terminal ‘F’,

connecting

a

voltmeter between this link and earth, and

running

the dynamo

up

to

about 1,000

rpm,

when

a

rising

voltage should be shown.

Inspect

the

wiring

of

the charging

circuit

and

carry

out

continuity

tests

between the dynamo, control box,

and

battery.

Check the

earth

connections,

particularly that of the

control box.

In

the

event

of

reported undercharging,

ascertain

that this

is

not

due

to

low

mileage.

Voltage regulator (open

circuit)

METHOD OF ADJUSTMENT

Checking and adjusting should be

completed

as

rapidly

as

possible

to

avoid

errors

due

to

heating

of the

operating

coil.

Withdraw the cables from the

control box

terminal blades

‘B’. To enable the

engine

to

be started

it

will

be

necessary

to

join

the

ignition

and battery feeds

together with

a

suitable lead. Connect

a

first-grade

0—20

moving-coil

voltmeter between control box

terminal ‘D’

and

a

good

earthing

point.

A

convenient

method of

making this

connection is

to

withdraw the

ignition

warning

light

feed

from the

control box

terminal ‘WL’ and

to

clip the

voltmeter lead

of

appropriate

polarity

to

the

small

terminal

blade thus exposed, this terminal being

electrically

common

with terminal

‘D’. Start

the

engine

and

run

the

dynamo

at

3,000

rpm.

The voltmeter reading should

be steady

and lie

between

the

appropriate

limits

according

to

the

temperature

(see

‘GENERAL

DATA’).

N.8

An

unsteady

reading

may

be due

to

dirty

contacts.

If the

reading

is

steady but

occurs

outside the

appropriate

limits

an

adjustment

mu

st

be made. Proceed

as

follows.

Stop the

engine

and

remove

the

control

box

cover.

Restart

the

engine

and

run

the dynamo

at

3,000

rpm.

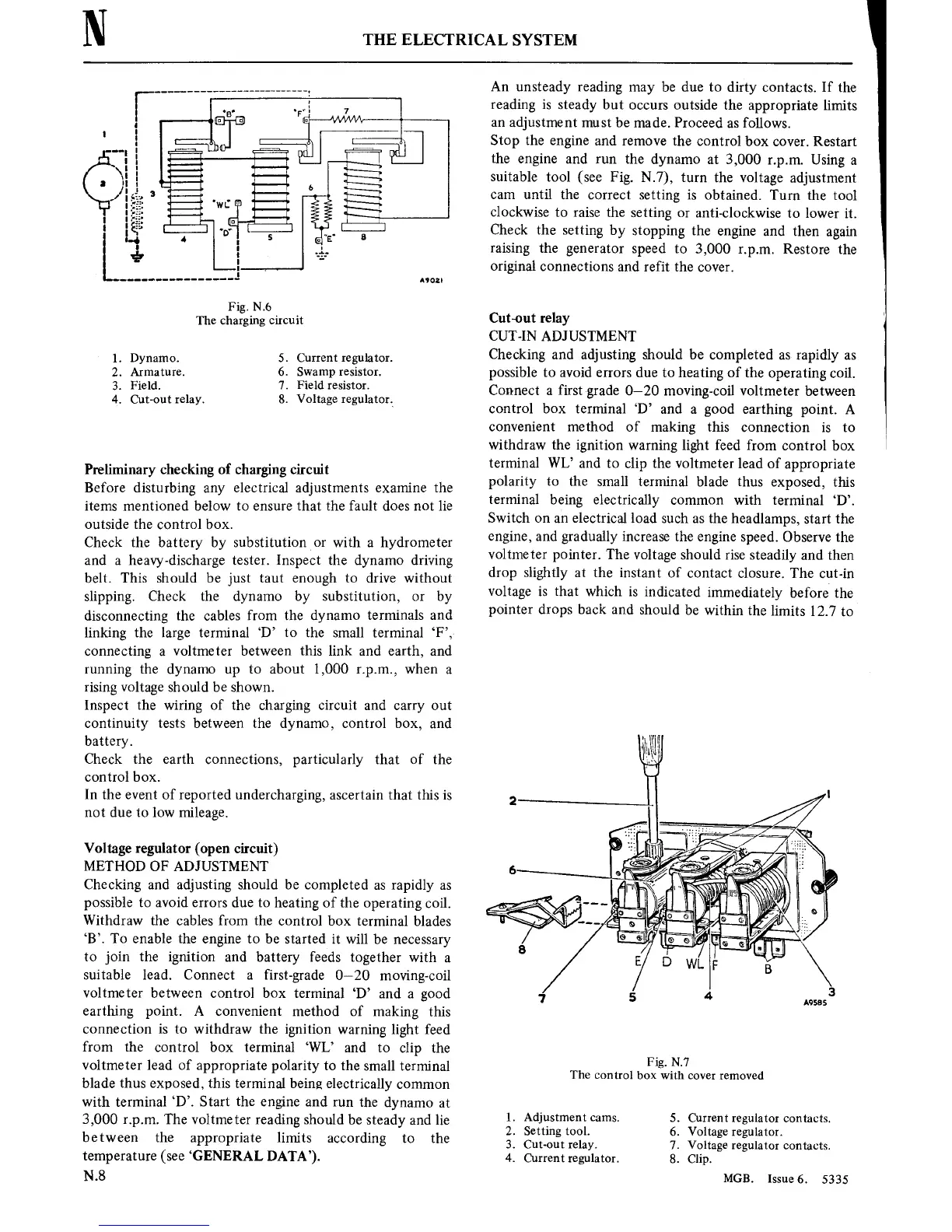

Using

a

suitable tool

(see

Fig. N.7),

turn

the

voltage

adjustment

cam

until the

correct

setting is

obtained.

Turn the

tool

clockwise

to

raise

the

setting

or

anti-clockwise

to

lower

it.

Check

the

setting

by

stopping

the

engine

and then

again

raising

the

generator

speed

to

3,000

rpm.

Restore

the

original

connections

and refit the

cover.

Cut-out relay

CUT-IN

ADJUSTMENT

Checking

and adjusting should be completed

as

rapidly

as

possible

to

avoid

errors

due

to

heating of the

operating

coil.

Connect

a

first

grade

0—20

moving-coil

voltmeter

between

control box terminal ‘D’ and

a

good earthing

point. A

convenient

method of making this

connection is

to

withdraw the

ignition

warning

light feed from

control

box

terminal WL’

and

to

clip the voltmeter

lead

of

appropriate

polarity

to

the

small terminal blade

thus

exposed, this

terminal

being electrically

common

with

terminal ‘D’.

Switch

on

an

electrical

load such

as

the

headlamps,

start

the

engine,

and gradually

increase

the

engine

speed. Observe

the

voltmeter

pointer.

The voltage should

rise

steadily

and then

drop slightly

at

the

instant

of

contact

closure. The

cut-in

voltage

is

that which

is

indicated

immediately

before

the

pointer

drops back

and

should be

within the limits

12.7

to

3

7

5

4

A9555

Fig.

N.7

The

control

box with

cover

removed

1.

Adjustment

cams.

5. Current

regulator

contacts.

2.

Setting tool.

6. Voltage

regulator.

3. Cut-out relay.

7. Voltage

regulator

contacts.

4.

Current regulator.

8. Clip.

MGB.

Issue6.

5335

Loading...

Loading...