N

‘

THE

ELECTRICAL

SYSTEM

Al275.

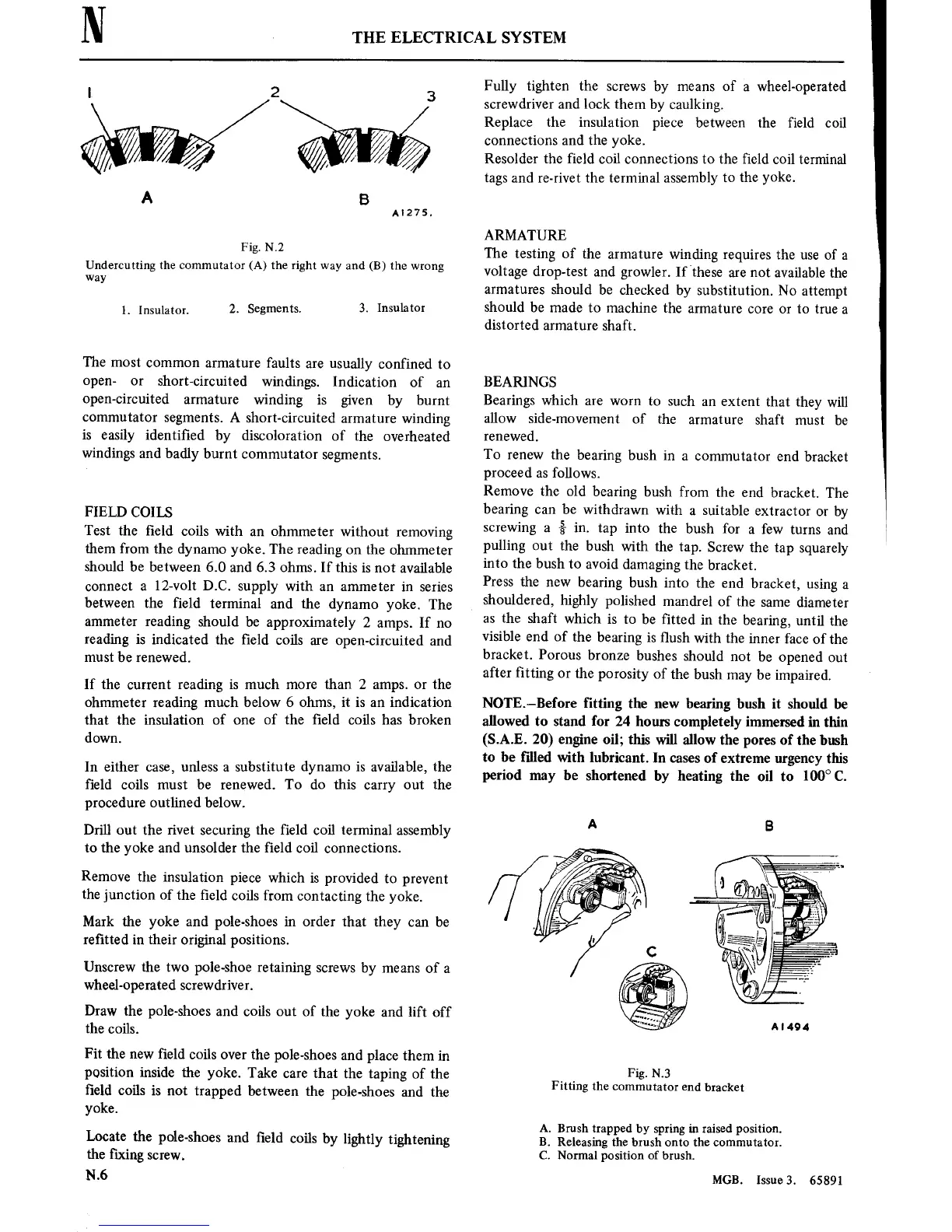

Fig.

N.2

Undercutting the

commutator

(A) the right

way

and (B) the

wrong

way

1. Insulator.

2. Segments.

3. Insulator

The

most

common

armature

faults

are

usually confined

to

open-

or

short-circuited

windings.

Indication

of

an

open-circuited

armature

winding

is

given

by burnt

commutator

segments.

A

short-circuited

armature

winding

is

easily identi■ed

by

discoloration of

the

overheated

windings

and badly burnt

commutator

segments.

FIELD COILS

Test the

■eld

coils with

an

ohmmeter

without

removing

them from

the dynamo

yoke. The

reading

on

the

ohmmeter

should be

between 6.0

and 6.3 ohms. If this

is

not

available

connect

a

12-volt D.C.

supply with

an

ammeter

in series

between the field

terminal

and

the

dynamo

yoke. The

ammeter

reading should

be

approximately

2

amps.

If

no

reading

is

indicated

the ■eld

coils

are

open-circuited

and

must

be

renewed.

If

the

current

reading

is

much

more

than

2

amps. or

the

ohmmeter reading much below 6

ohms,

it

is

an

indication

that the

insulation

of

one

of

the ■eld coils has broken

down.

In

either

case,

unless

a

substitute dynamo

is

available, the

field

coils

must

be renewed. To do

this

carry

out

the

procedure outlined below.

Drill

out

the

rivet securing

the field coil terminal

assembly

to

the yoke and unsolder the field coil

connections.

Remove

the

insulation

piece

which

is provided

to

prevent

the

junction of the ■eld

coils from

contacting

the

yoke.

Mark the

yoke and

pole-shoes

in

order that they

can

be

re■tted

in

their original

positions.

Unscrew the

two

pole-shoe

retaining

screws

by

means

of

a

wheel-operated

screwdriver.

Draw the

pole-shoes

and coils

out

of

the

yoke and lift off

the

coils.

Fit the

new

field

coils

over

the pole-shoes

and place them

in

position inside the

yoke. Take

care

that

the

taping

of the

■eld

coils

is

not

trapped between

the

pole-shoes

and the

yoke.

Locate the

pole-shoes

and ■eld

coils

by lightly

tightening

the ■xing

screw.

N.6

Fully tighten the

screws

by

means

of

a

wheel-operated

screwdriver

and

lock

them

by caulking.

Replace the insulation

piece between the field coil

connections

and

the

yoke.

Resolder the field coil

connections

to

the ■eld

coil

terminal

tags

and

re-rivet

the terminal

assembly

to

the yoke.

ARMATURE

The

testing

of the

armature

winding

requires

the

use

of

a

voltage

drop—test

and

growler. If

these

are

not

available

the

armatures

should

be checked

by

substitution.

No

attempt

should

be

made

to

machine

the

armature

core or

to true

a

distorted

armature

shaft.

BEARINGS

Bearings

which

are

worn

to

such

an

extent

that they

will

allow

side-movement

of

the

armature

shaft

must

be

renewed.

To

renew

the

bearing

bush

in

a

commutator

end bracket

proceed

as

follows.

Remove

the

old bearing

bush from

the end

bracket.

The

bearing

can

be

withdrawn

with

a

suitable

extractor

or

by

screwing

a

%

in.

tap

into

the

bush for

a

few

turns

and

pulling

out

the

bush

with the

tap.

Screw

the

tap

squarely

into

the bush

to

avoid damaging

the

bracket.

Press

the

new

bearing

bush

into

the

end bracket,

using

a

shouldered,

highly

polished

mandrel

of the

same

diameter

as

the

shaft

which

is

to

be ■tted

in

the

bearing,

until

the

visible

end of

the

bearing

is

■ush

with the

inner

face of

the

bracket.

Porous

bronze

bushes

should

not

be

opened

out

after ■tting

or

the

porosity

of

the bush

may

be

impaired.

NOTE—Before

fitting the

new

bearing bush

it should be

allowed

to

stand for

24

hours

completely

immersed

in

thin

(S.A.E. 20)

engine

oil; this

will allow the

pores

of

the bush

to

be

filled

with

lubricant.

In

cases

of

extreme

urgency

this

period

may

be shortened

by heating the

oil

to

100°

C.

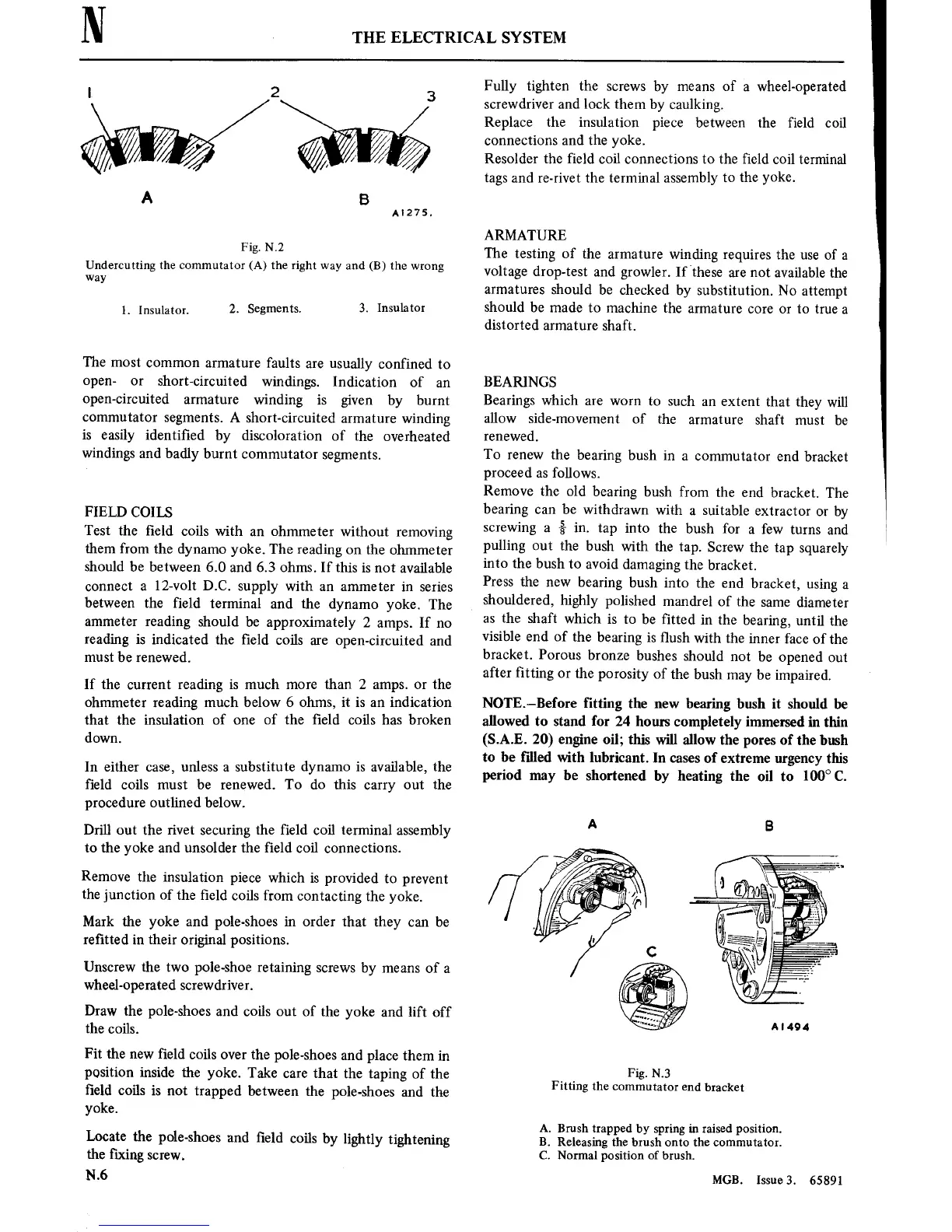

Fig.

N.3

Fitting

the

commutator

end

bracket

A.

Brush

trapped by spring in raisedposition.

B. Releasingthe brush

onto

the

commutator.

C. Normal position of brush.

MGB.

Issue3. 65891

Loading...

Loading...