M

THE

BRAKING

SYSTEM

To

remove

the

wheel cylinder disconnect the brake ■uid

supply

pipe,

placing

a

container

to

catch the ■uid.

Withdraw the circlip

and

retaining

washer and

remove

the

cylinder.

Extract

the split

pin

and

withdraw the

clevis

pin

to

release

the hand

brake cable from the lever. Detach the rubber dust

cover

from the brake

lever

at

the

rear

of the backplate and

withdraw the

lever.

Withdraw the

tappets

from the spindle adjuster and

screw

the

adjusting spindle inwards until clear

of

the threads.

Remove the

two nuts

and

spring

washers from the

rear

of

the backplate

to

release

the

adjuster body.

Assembling

Thoroughly

clean

the adjuster body,

tappets,

and

adjuster.

Smear the adjuster threads and

tappets

with Lockheed

Expander Lubricant. Screw the adjuster fully home

and

slide the

tappets

into

the body,

ensuring

that

the tapered

portion

on

each

is

facing

inwards.

Examine the rubber seals

on

both

pistons

and

renew

them

should they

appear

damaged

or

distorted.

It

is

usually

advisable

to

renew

the rubbers when

rebuilding the

cylinders. Smear all internal

parts

with ■uid

and

reassemble. Replace the dust

covers.

Hold the cylinder

up

against

the backplate and replace the ■at

washer and

circlip.

Reconnect

the ■uid

supply

pipe.

Hold the brake lever

against

the backplate

and

replace

the

rubber

boot. Reconnect the

hand

brake cable.

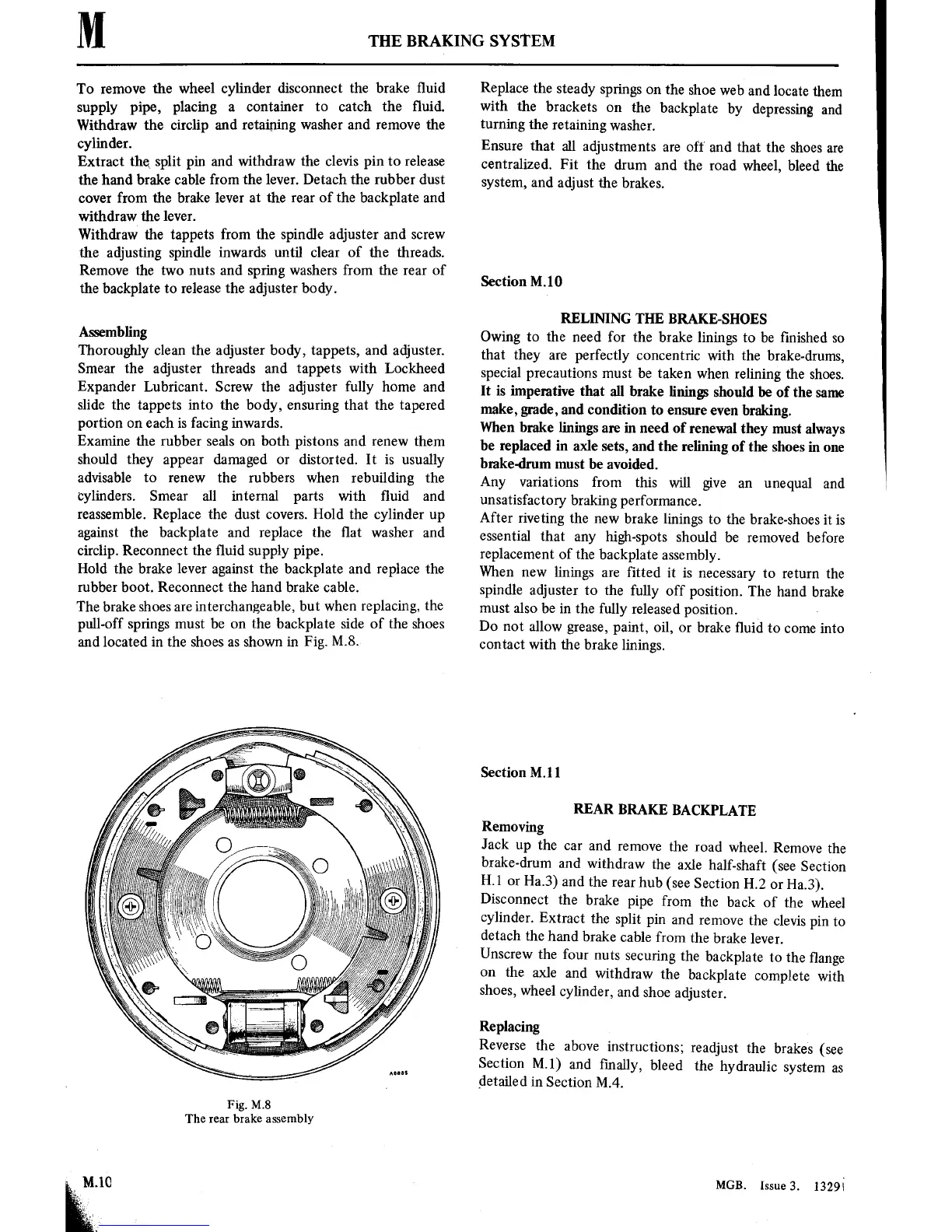

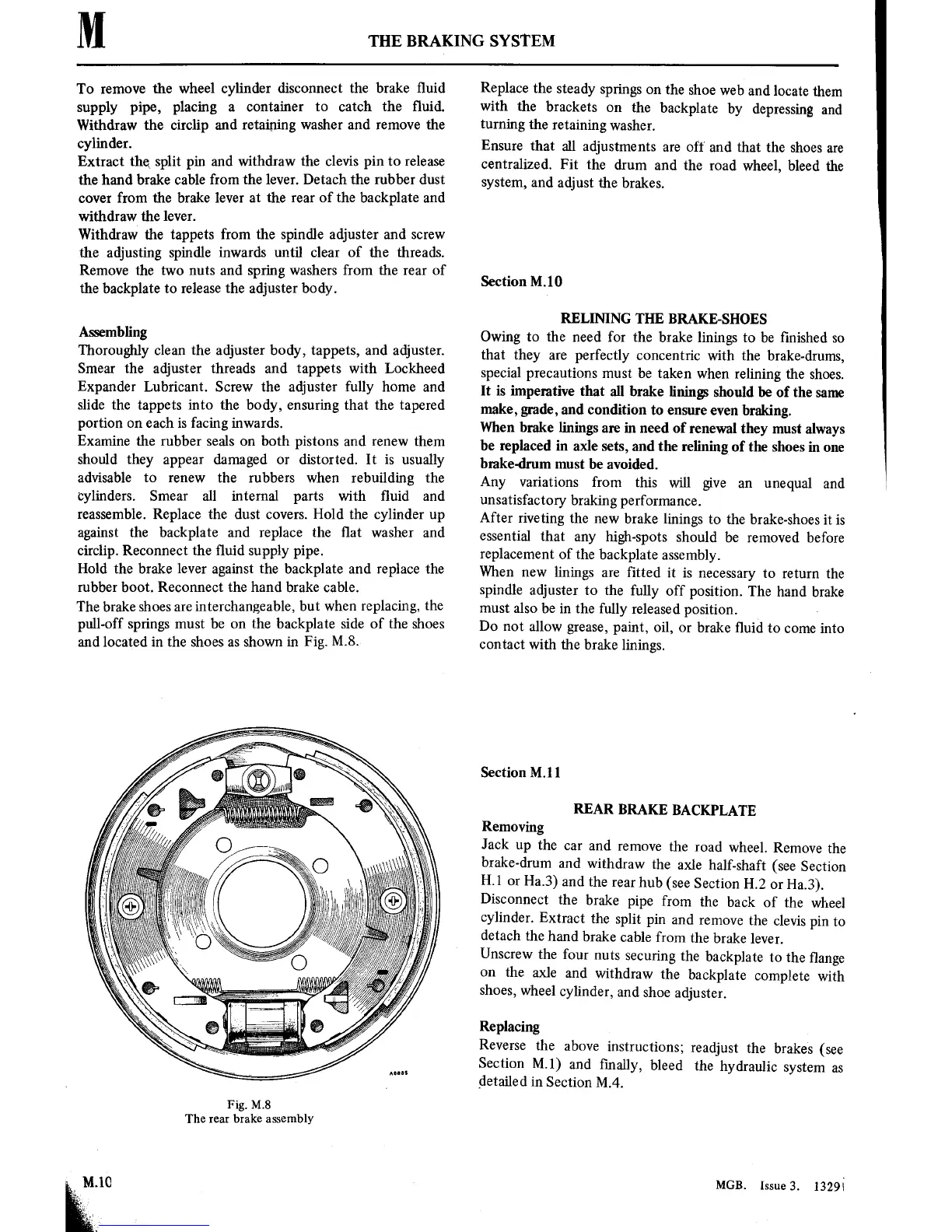

The brake shoes

are

interchangeable,

but when

replacing, the

pull-off

springs

must

be

on

the backplate side of the

shoes

and located

in

the shoes

as

shown

in

Fig.

M.8.

Fig. MS

The

rear

brake assembly

Replace

the

steady

springs

on

the

shoe

web

and locate

them

with

the

brackets

on

the

backplate

by

depressing

and

turning

the

retaining

washer.

Ensure

that

all adjustments

are

off

and that the

shoes

are

centralized.

Fit the

drum

and the

road wheel, bleed

the

system,

and

adjust the brakes.

Section

M. 10

RELINING

THE

BRAKE-SHOES

Owing

to

the need for

the brake

linings

to

be ■nished

so

that they

are

perfectly

concentric

with the brake-drums,

special

precautions

must

be taken

when relining the

shoes.

It

is imperative that

all brake linings

should

be

of

the

same

make,

grade, and

condition

to

ensure

even

braking.

When

brake linings

are

in

need of

renewal they

must

always

be replaced

in

axle

sets,

and the

re■ning

of the shoes

in

one

brake-drum

must

be avoided.

Any

variations

from

this

will

give

an

unequal and

unsatisfactory

braking

performance.

After

riveting

the

new

brake linings

to

the

brake-shoes

it is

essential that

any

high-spots

should

be

removed before

replacement

of

the backplate

assembly.

When

new

linings

are

fitted

it is

necessary

to return

the

spindle

adjuster

to

the fully

off

position.

The

hand

brake

must

also be

in

the fully

released

position.

-

Do

not

allow

grease,

paint,

oil,

or

brake

■uid

to

come

into

contact

with the

brake

linings.

Section

M.ll

REAR

BRAKE

BACKPLATE

Removing

Jack

up

the

car

and

remove

the

road

wheel.

Remove

the

brake-drum

and

withdraw

the

axle half-shaft

(see

Section

H.l

or

Ha.3)

and the

rear

hub (see

Section

H2

or

Ha.3).

Disconnect

the

brake

pipe

from

the

back

of the

wheel

cylinder.

Extract

the

split

pin

and

remove

the

clevis

pin

to

detach

the

hand

brake

cable

from

the brake

lever.

Unscrew

the

four

nuts

securing

the

backplate

to

the ■ange

on

the

axle

and

withdraw

the

backplate

complete

with

shoes,

wheel

cylinder,

and

shoe

adjuster.

Replacing

Reverse

the

above

instructions;

readjust

the

brakes (see

Section

MI)

and ■nally,

bleed

the

hydraulic

system

as

detailed

in

Section

M.4.

MGB.

Issue3.

1329i

Loading...

Loading...