12 Maintenance and Troubleshooting

Action B: Test the outlet. If there is no power, contact electrician.

Cause C: Plug prongs bent so that contact not made at outlet.

Action C: Unplug the power cable and re-plug into outlet. If indicator does not illuminate,

have electrician adjust prongs or replace outlet or plug.

Cause D: Power cord damaged.

Action D: Have electrician check cord using test meter. Replace if defective.

Cause E: Loose internal connection, broken wire, or failure of internal power supply.

Action E: Contact a Micromeritics Service Representative for repair or replacement

information.

Specified pressure not reached or maintained.

Cause A: Chamber cap not properly closed.

Action A: Close chamber cap by turning fully clockwise.

Cause B: Chamber cap contains dust or debris or the O-ring is not properly greased.

Action B: Using a lint free tissue, clean the chamber cap and the rim of the cell chamber.

Lightly grease the chamber cap O-ring. See Chamber Cap O-Ring on

page12 - 5.

Cause C: The chamber cap O-ring is not properly seated.

Action C: Check the chamber cap. Ensure that the O-ring is properly seated and that it

contains no scratches or cuts.

Cause D: The chamber cap O-ring is cut or scratched.

Action D: Replace the O-ring in the chamber cap. See Chamber Cap O-Ring on

page12 - 5.

Cause E: Gas leaks in the cell chamber or expansion chamber.

Action E: Check the pycnometer for leaks. SeeCheck the Cell and Expansion Cham-

bers for Leaks on page12 - 7.

Cause F: The helium tank is low on gas or empty. Tank pressure should be at least 200

psi above regulator pressure.

Action F: Check tank. Minimum recommended pressure is 200 psig above regulator pres-

sure. See Regulator Pressure on page12 - 15.

Cause G: The shut-off valve on the gas cylinder is closed.

Action G: Ensure that the valve is open.

Cause H: The Zero offset (of pressure transducer) is too low.

12 - 2

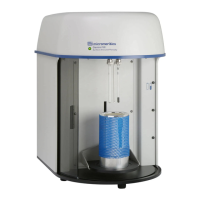

AccuPyc II 1345 Operator Manual

134-42851-01 (Rev A) — Jan 2021

Loading...

Loading...