7.3 Calibrating Platinum Resistance Thermometer

E5EK

7--7

7.3 Calibrating Platinum Resistance Thermometer

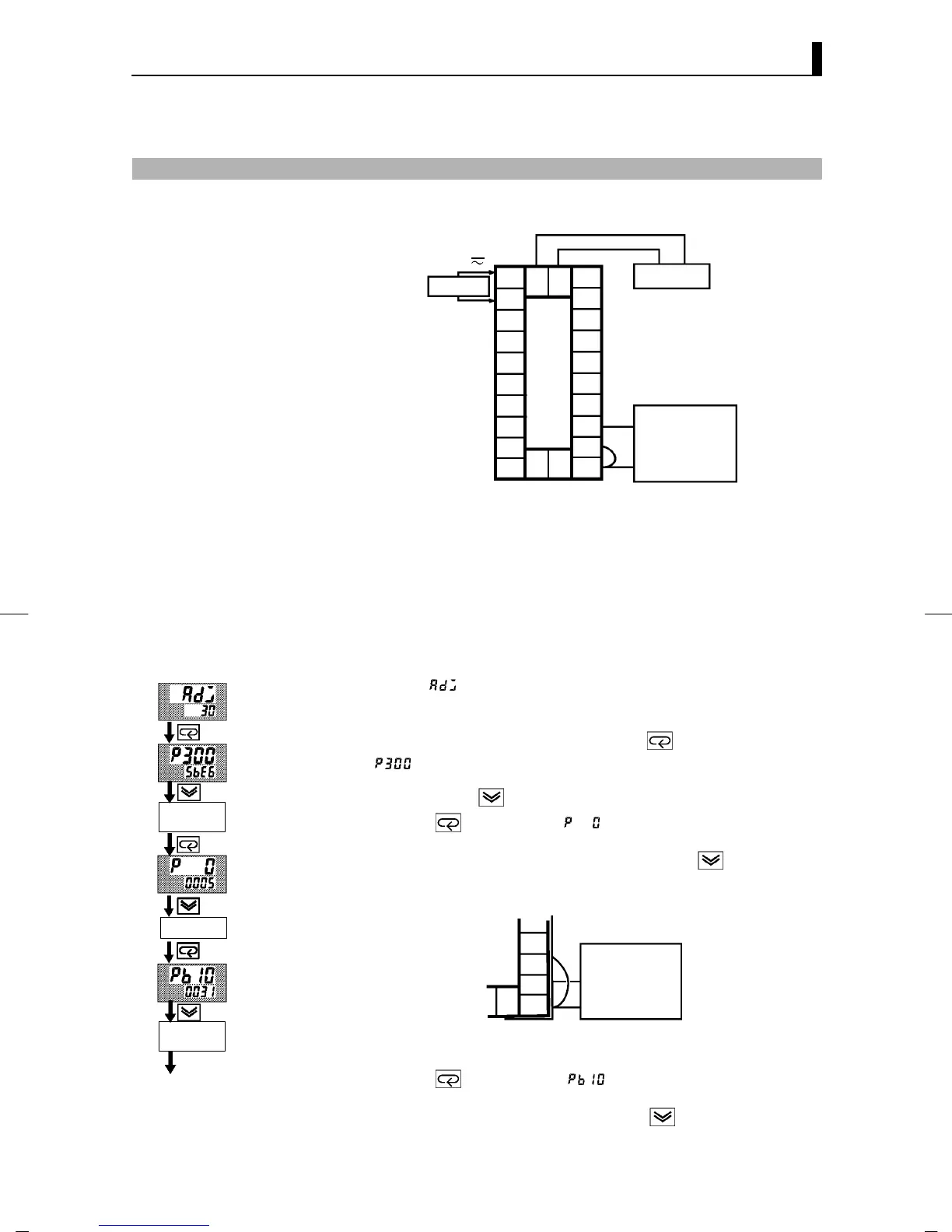

F Preparation

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

21 22

23

DMM

6-dial

SOURCE

AC100-240V

(AC/DC24V )

~

• Useleadsofthesamethickness whenconnectingtotheplatinum

resistance thermometer.

• In the above figure, 6-dial refers to a precision resistance box, and

DMM stands for a digital multimeter. However, note that the DMM is

required only when the transfer output function is supported.

• Connect (short) the leads from terminal Nos. 11 and 12.

This example describes how to calibrate a p latinum resistance ther-

mometer when the transfer output function is supported. If the transfer

output function is not supported, skips steps (7) to (10).

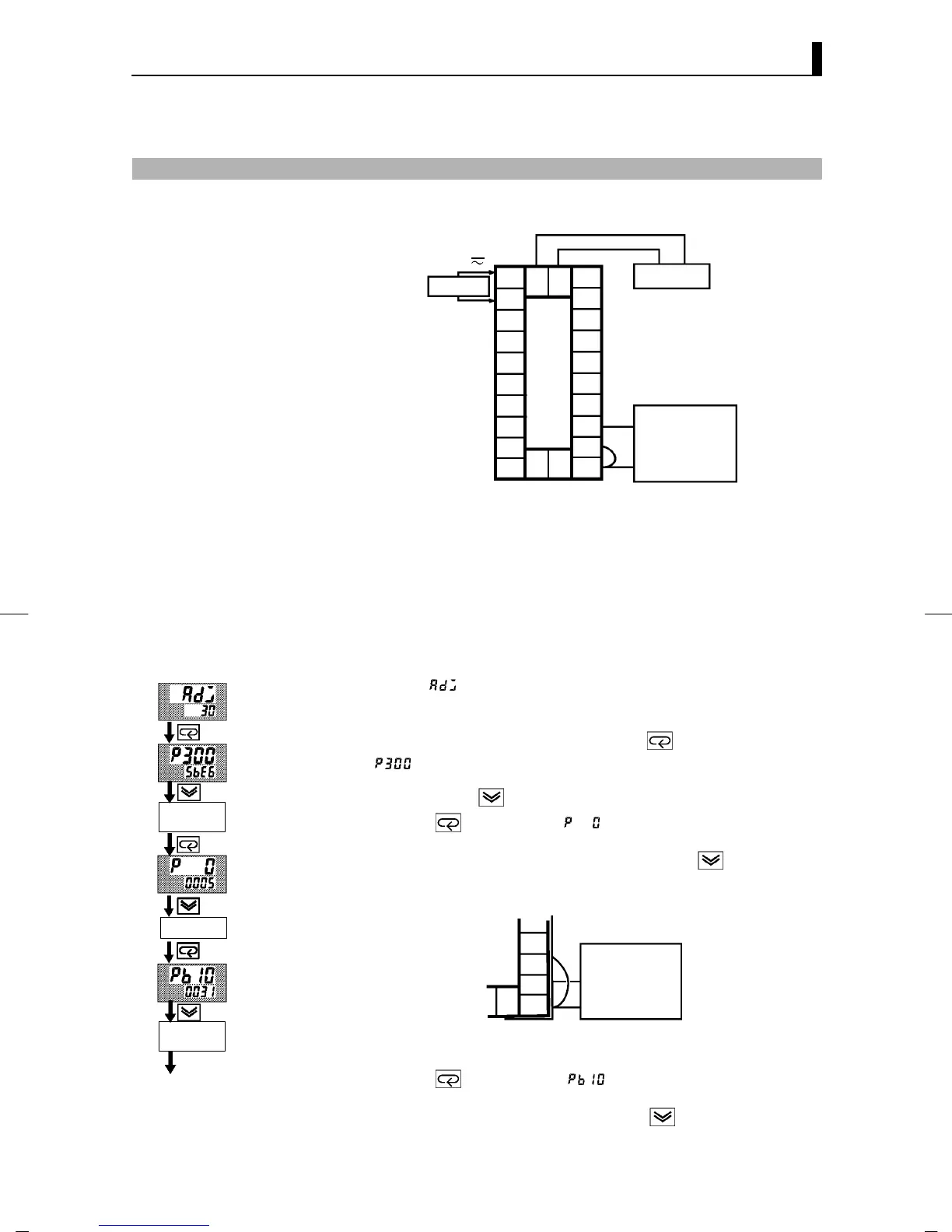

(1) When [

] is displayed, the 30 -minute timer is displayed on the

No.2 display and counts down. This timer serves as a guide for the

aging time when agin g is required.

(2) First, calibrate the main input. Press the

key to display

[

] (300Ω calibration display). Set the 6-dial to 300Ω. When the

value on the No.2 display has stabilized (changes of several digits

max.), press the key to temporarily store the calibration data.

(3) Pr ess the

key to switch [ ](0Ω calibration) display. Short

terminal No. 11 to 13. When the value on the No.2 display has sta-

bilized (changes of several digits max.), press the

key to tempo-

rarily store the calibration data.

(4) Next, calibrate the B-B’ input. Change the wiring as follows.

15

14

13

12

11

6-dial

Make the conn ection across terminals 11 and 12 and the 6-dial as

short as possible. Short terminals 11 and 13.

(5) Pr ess the

key to display [ ](10Ω calibration display). Set

the6-dialto10Ω.. When the value on the No.2 display has stabilized

(changes of several digits max.), p ress the

key to temporarily

store the calibration data.

F Calibration

Cont’d on next page

Change wi ring.

Short terminal

Nos.11 to 13

Short terminal

Nos.11 to 13

Loading...

Loading...