6-7

6-1-6 Startup Torque Compensation

With

open-loop vector control, a starting-torque compensation can be input to decrease the torque ref

-

erence’s rise time at startup.

This

function is ef

fective for equipment in which a starting torque is required, such as machinery with a

high friction load or cranes. Unlike flux vector control, the compensation is input only at startup.

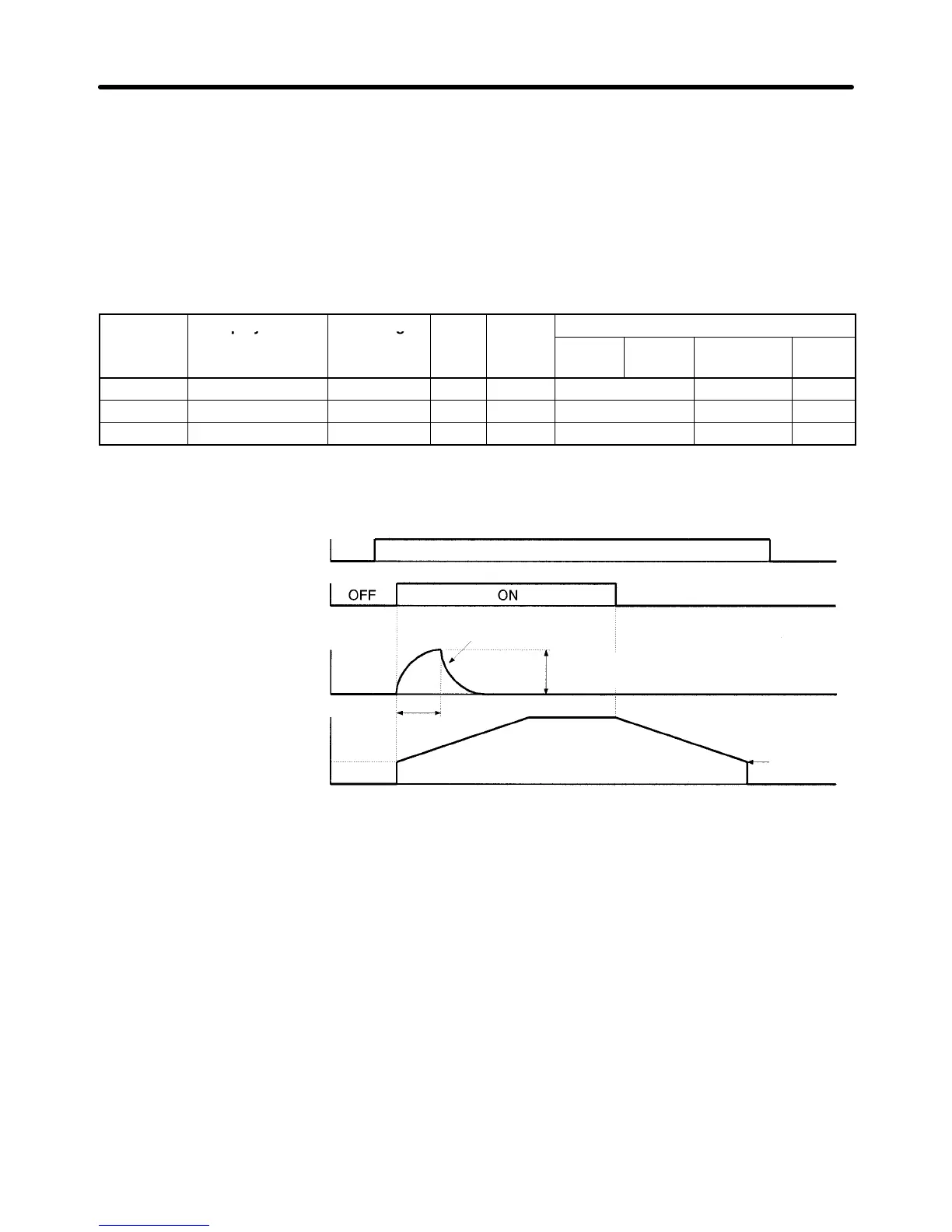

H Starting-torque Compensation Function Settings

Parameter Display name Setting Units Default

Valid access levels

number

range setting

V/f

Control

V/f with

PG

Open Loop

Vector

Flux

Vector

C4-03 F TorqCmp@start 0.0 to 200.0 0.1% 0.0 --- Advanced ---

C4-04 R TorqCmp@start –200.0 to 0.0 0.1% 0.0 --- Advanced ---

C4-05 TorqCmp Delay T 0 to 200 1 ms 10 --- Advanced ---

These parameters cannot be changed during operation.

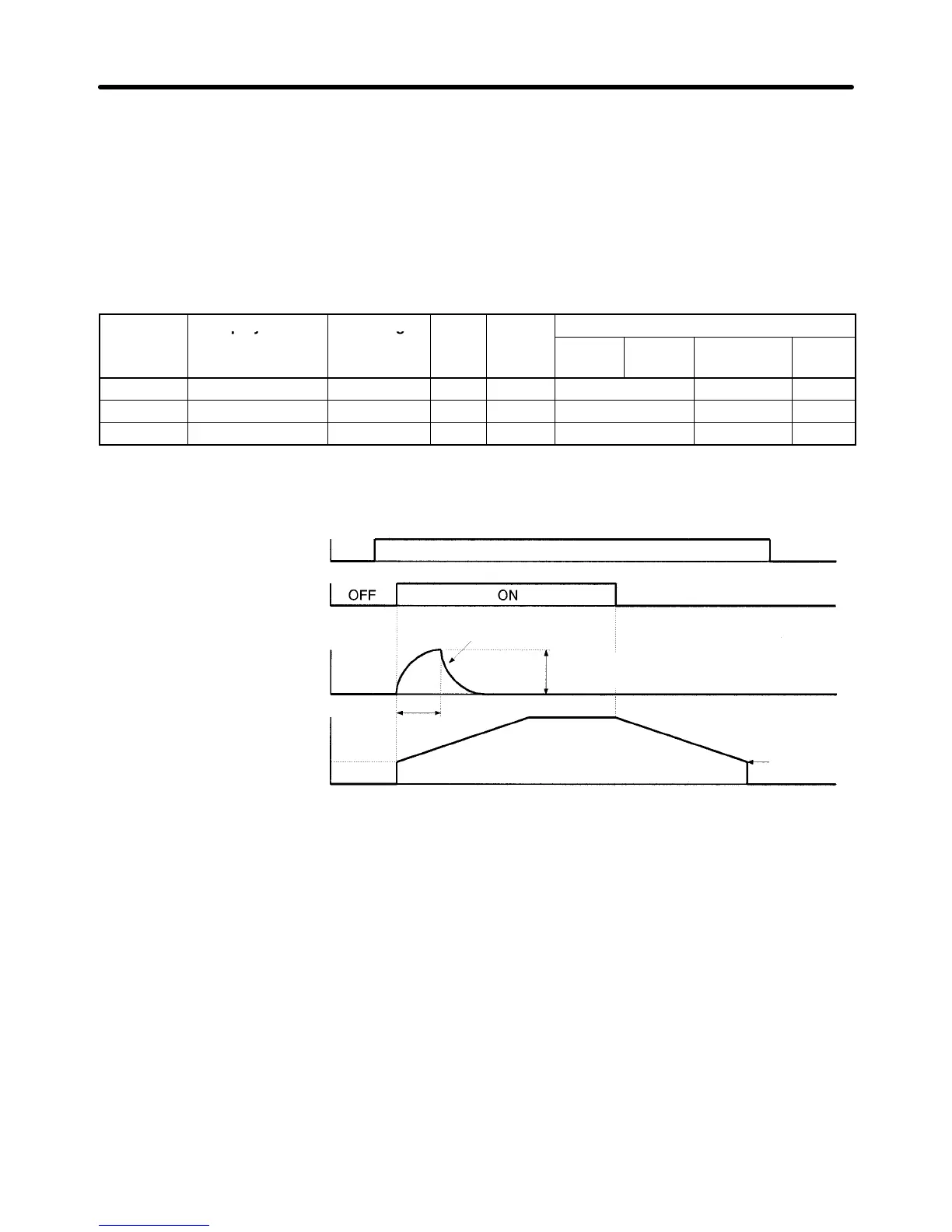

Timing Chart

Note The Inverter’s torque reference value is at its lower limit

with the torque compensation value shown above.

Frequency reference

Run command

Torque compensation value

Time constant: C4-02

C4-03 (forward)

C4-04 (reverse)

C4-05 ×

4

E1-09

Output frequency

Larger of b2-01

and E1-09

• When

using this compensation function, set the starting-torque compensation value to the friction load

in regular machinery or the lifting/lowering load for machinery such as cranes.

Friction loads:

Set the friction load in both C4-03 and C4-04.

Lifting/lowering load:

Set

the electrically driven (winding) load only

. (When the lifting machinery is equipped with a coun

-

terweight,

a shock may be generated if there is a regenerative load so do not use this function.)

• It

is

only possible to set the electrically driven compensation in both forward and reverse. (The regen

-

erative setting cannot be made.)

• The

starting-torque compensation is not

applied when switching between forward and reverse or after

a speed search.

• The starting-torque compensation is usually not applied when using a second motor.

Advanced Operation Chapter

6

Loading...

Loading...