5-41

H Adjusting Speed Loop (ASR) Responsiveness (C5-06) and Integral

Limit (C5-08)

Normally

it isn’t necessary to make this adjustment, but parameter C5-06 can be used when adjusting

the

gain doesn’t remove motor vibration, or adjusting the gain removes vibration but results in poor re

-

sponsiveness. A high C5-06 setting lowers the responsiveness

of

the speed control loop, but makes it

difficult for vibration to develop. This parameter cannot be changed during operation.

Parameter Display name Setting range Units Default

Valid access levels*

number

setting

V/f

Control

V/f with

PG

Open Loop

Vector

Flux

Vector

C5-08 ASR 1 Limit 0 to 400 --- 400 X X X A

The

setting of C5-08 does not normally need to be changed. It is used to set an upper limit for the integral

used

in speed control. Set a smaller value if rapid changes in the load can damage the load or cause the

motor to become disengaged due to Inverter

responsiveness.

If the setting is too small, however

, it may

become impossible to perform speed control.

5-4-5 Adjusting Speed Control Loop (ASR) Gain

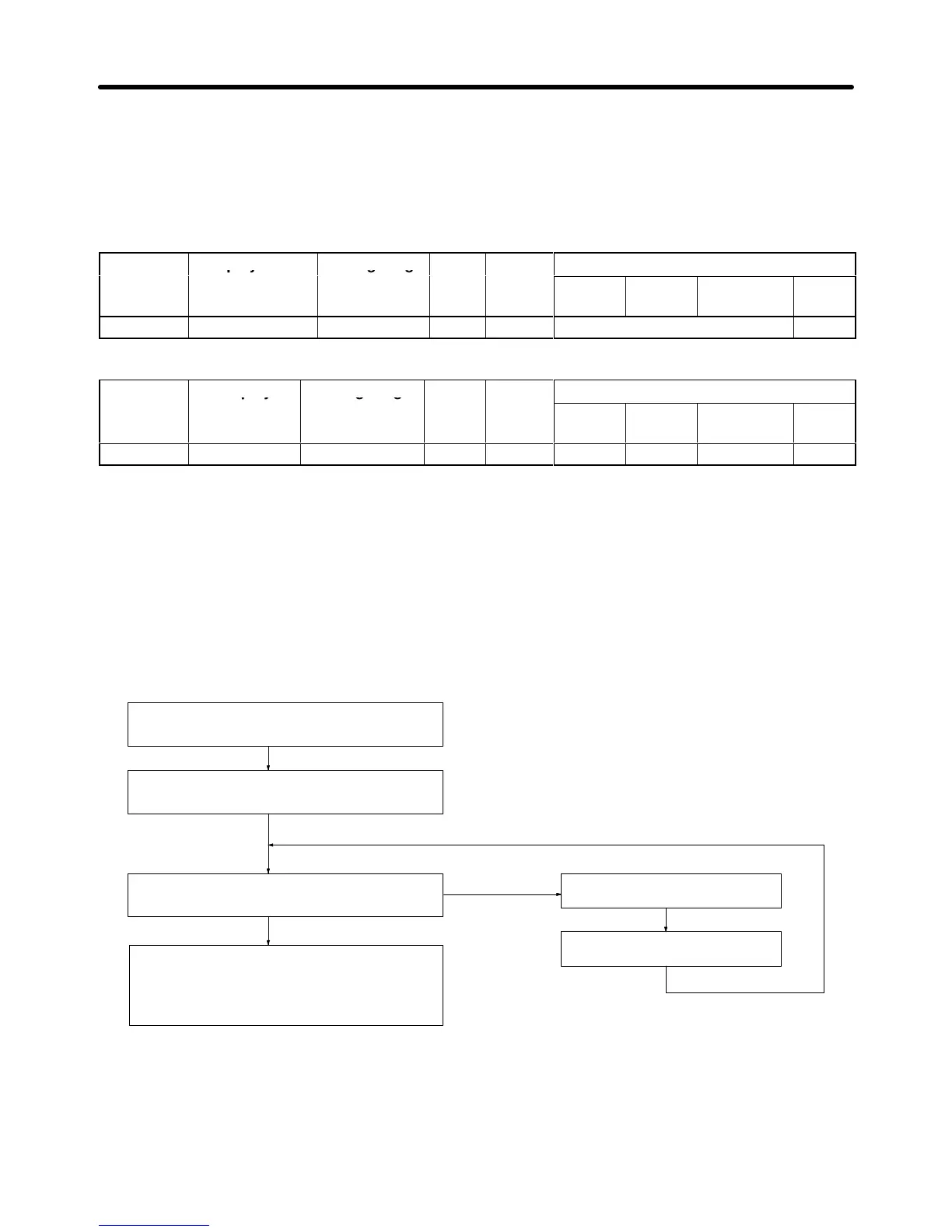

H Gain Adjustment Procedure

Use

the following procedure to adjust the gain with the mechanical

system and actual load connected.

At zero-speed, increase C5-01 (ASR P Gain 1)

until there is no vibration.

At zero-speed, decrease C5-02 (ASR I Time 1)

until there is no vibration.

Does vibration develop when the motor operates

at the maximum normal operating speed?

Adjustment completed.

(When there is higher-level position control, ad-

just the position loop gain so that overshooting/

undershooting doesn’t occur.)

NO

YES

Decrease C5-01 (ASR P Gain 1).

Increase C5-02 (ASR I Time 1).

H Fine Adjustments

When

you want even finer gain adjustment, adjust the gain while observing the speed waveform. Pa

-

rameter

settings like those shown in the following table will be necessary to observe the speed wave

-

form.

Basic Operation Chapter

5

Loading...

Loading...