6-98

•

There are some monitor items that are limited to the 0 to +10 V signal range even when the 0- to

±10-V

signal level has been selected. Refer to the table of status monitor items in page 3-12 for details.

6-5-8 Protective Functions: L

H Motor Protection Settings (L1)

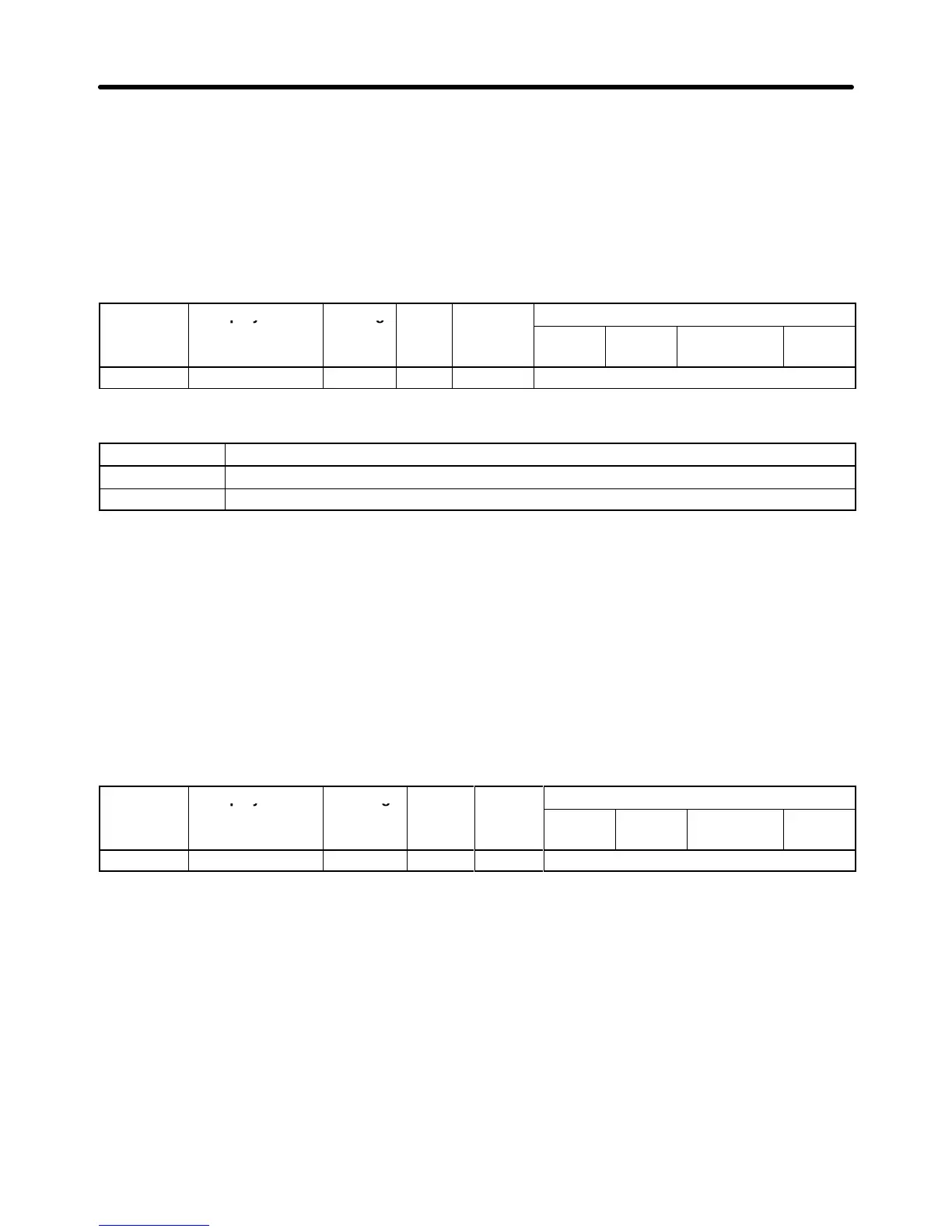

Parameter Display name Setting Units Default

Valid access levels

number

range setting

V/f

Control

V/f with

PG

Open Loop

Vector

Flux

Vector

L1-01 MOL Fault Select 0 or 1 --- 1 Basic or Advanced

Note This parameter cannot be changed during operation.

Setting Function

0 Disabled.

1 Enabled.

• This setting enables or disables the motor overload protection function.

• The rated current setting (E2-01) is used as a basis for overload detection.

• Disable

the motor protection

function (setting 0) when two or more motors are connected to a single

Inverter.

Use another method to provide overload protection separately to each motor

, such as

con

-

necting a thermal relay to the power line of each motor.

• The motor protection function may not protect a motor when the power supply is turned on and off

frequently, because the thermal value is reset each time that the power is turned off.

• If

the Overload OL1 alarm (1F) is set in one of the multi-function outputs (H2-01 through H2-03), the

output will be turned ON when the electronic thermal value reaches 90% of the overload detection

level.

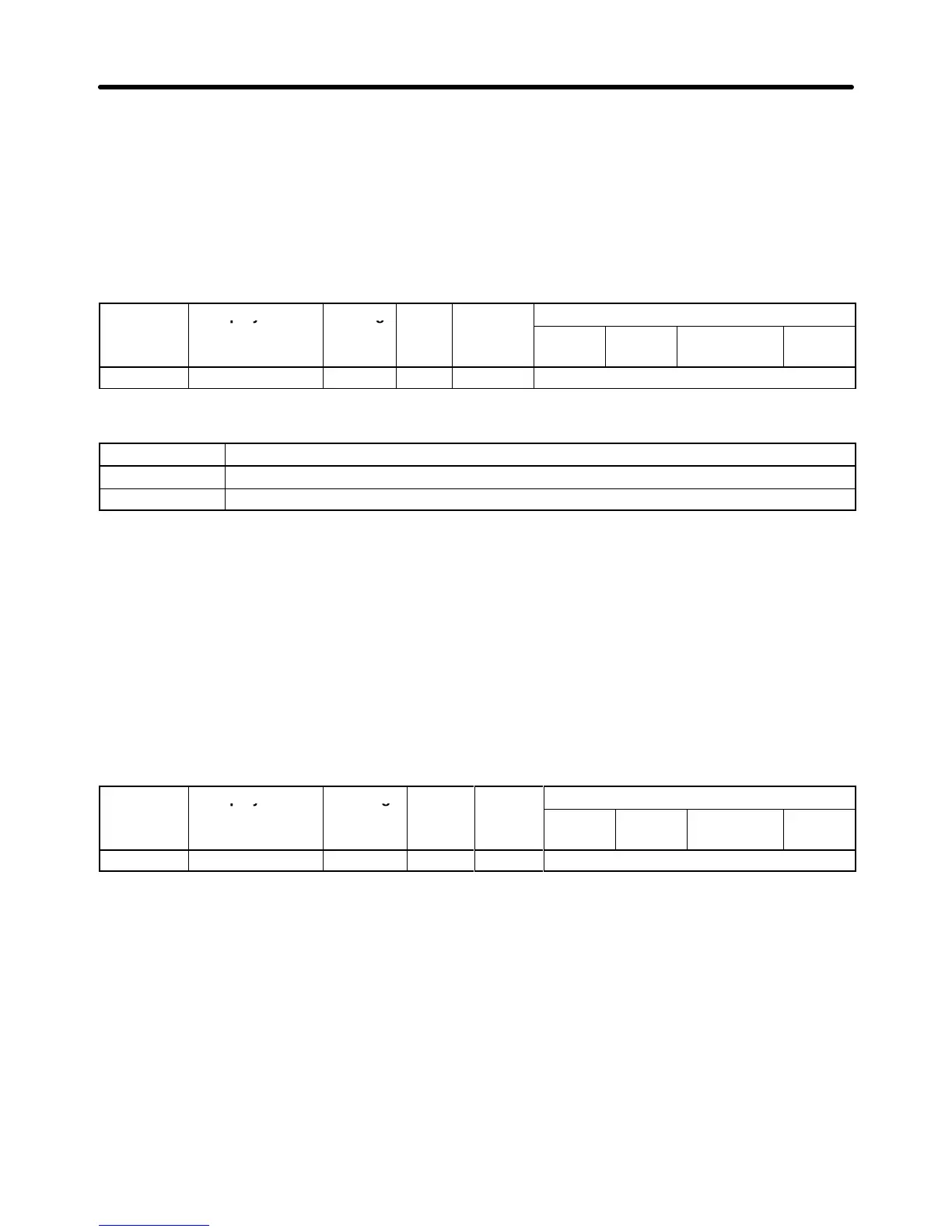

Parameter Display name Setting Units Default

Valid access levels

number

range setting

V/f

Control

V/f with

PG

Open Loop

Vector

Flux

Vector

L1-02 MOL Time Const 0.1 to 5.0 Minutes 1.0 Basic or Advanced

Note This parameter cannot be changed during operation.

• Normally

it isn’t necessary to change this setting. (The default setting is a 150%, 1 minute endurance.)

• This setting specifies the electronic thermal detection time.

• Set the protection time for a 150% load imposed after hot-starting and continuously operating the

Inverter

with a

rated current. Set the protection time at rated speed if a general-purpose motor is used.

The rated current of the general-purpose motor will decrease if the frequency drops. Therefore, the

Inverter will automatically shorten the detection time at low frequency.

• When

the motor

’

s overload endurance level is known, set the hot-start overload resistance level for

the motor, but be sure to allow some margin for safety.

• Decrease this setting when you want to detect an overload more quickly.

Advanced Operation Chapter

6

Loading...

Loading...