3-3

3-2 Modes

This section describes the 3G3FV’s various parameter setting and monitoring modes.

S Inverter Modes

• The SYSDRIVE 3G3FV Inverter’s parameters and monitoring functions have been organized in

groups,

so it is easier to make settings and read data.

These function groups are known as modes.

• The 3G3FV is equipped with 5 modes, as shown in the following table.

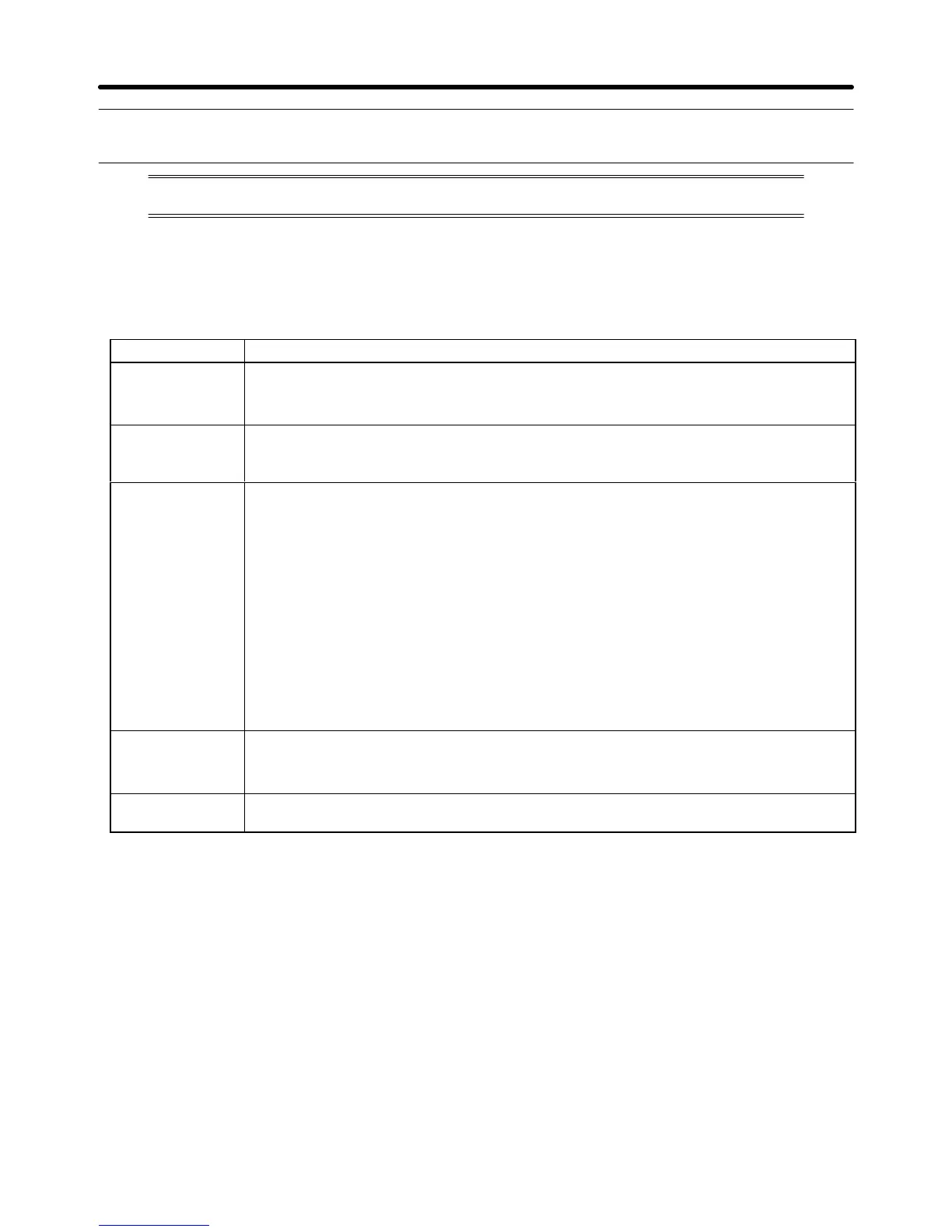

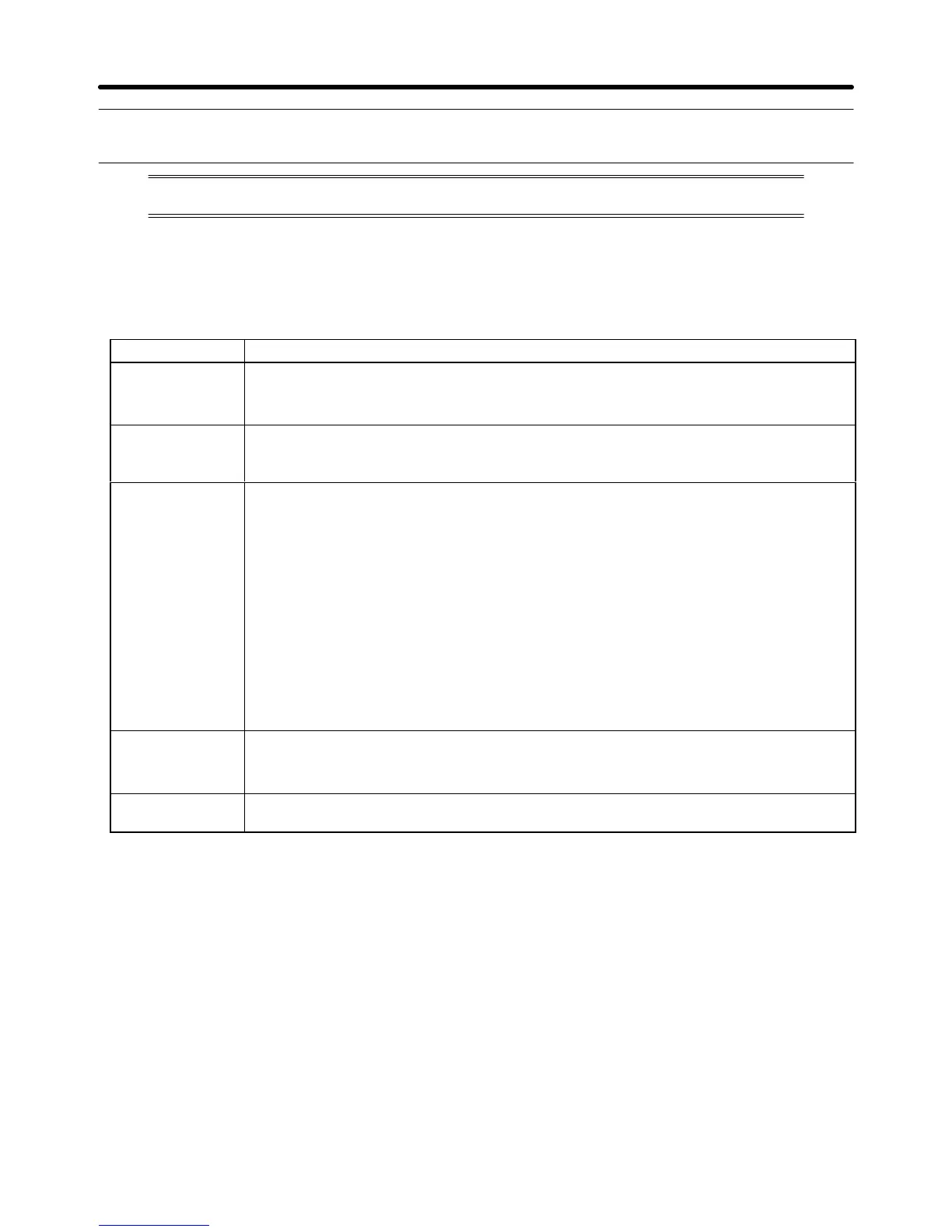

Mode Primary function(s)

Operation mode The Inverter can be run in this mode.

Use this mode when monitoring values such as frequency references or output

current, displaying fault information, or displaying the fault history.

Initialize mode Use this mode when selecting the language displayed on the Digital Operator,

selecting the access level for setting/reading parameters, selecting the control mode,

or initializing the parameters.

Program mode Use this mode when setting/reading the parameters required for operation. The

program-mode functions are subdivided into the following groups:

Application: Operation mode selection, DC control, speed search, etc.

Tuning: Acceleration/deceleration times, S-curve characteristics, carrier

frequencies, etc.

Reference: Settings related to frequency control

Motor: V/f characteristics and motor parameters

Option: Settings for Optional Cards

Terminal: Settings for sequential I/O and analog I/O

Protection: Settings for the motor and inverter protection functions

Operator: Selects the Digital Operator’s display and key functions

Auto-tuning

mode

(Usable only with the vector control mode)

Use this mode when running a motor with unknown motor parameters in the vector

control mode. The motor parameters are calculated and set automatically.

Modified

constants mode

Use this mode to set/read parameters that have been changed from their factory-set

values.

S Switching Modes

• Once

the Unit has been put into operation mode by pressing the Menu Key

, the Increment and Decre

-

ment Keys can be pressed to switch to other modes.

• Press the Enter Key to set/read the parameters in each mode.

Preparing for Operation Chapter

3

Loading...

Loading...