3

Figure 4 - TESTING PINION MOVEMENT AND PULL-

IN WINDINGS (GROUND-FLOAT TYPE)

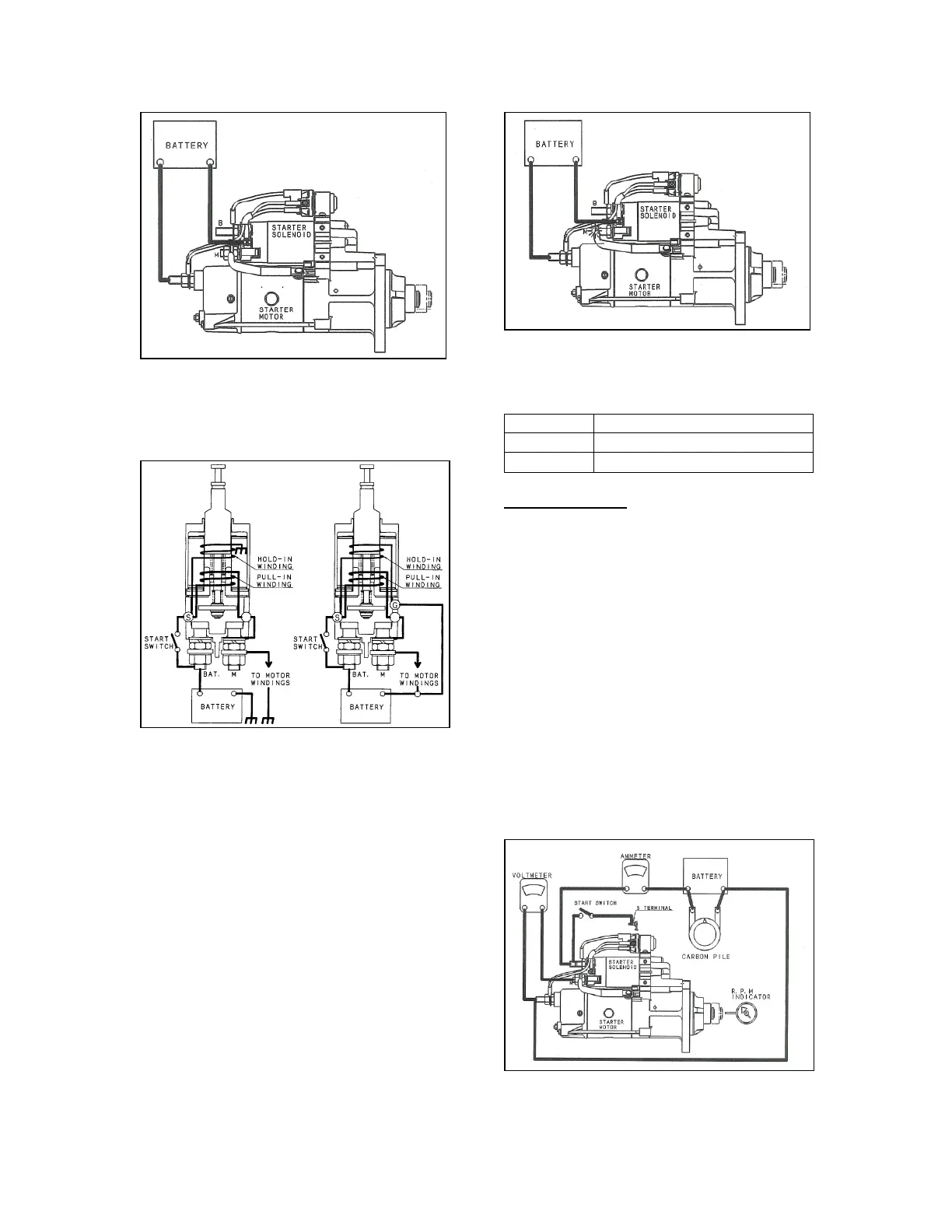

For the starter switch coils, refer to the

switch circuit diagrams for the ground-wire

type (ground-float type) shown in figures 5.

Figure 5 - SOLENOID CIRCUIT (GROUND-FLOAT

TYPE)

If the pinion is performing properly, follow

the procedure as described below to inspect

the H-coil in the starter solenoid.

Remove the M-terminal nut as described in

figure 6 and keep the lead wire end in

contact with the M-terminal. Apply voltage

between the S-terminal and the ground to let

the pinion advance forward. Immediately

after that, separate the lead wire from the M-

terminal and check if the pinion stays in the

advanced forward position while voltage is

applied to the H-coil only. If the pinion

returns, replace the starter. The H-coil is

assumed to be layer-shorted.

* M-terminal nut tightening torque: 20 to 30

N⋅m

Figure 6 - TESTING HOLD-IN WINDINGS (GROUND-

FLOAT TYPE)

Below are the resistance values for the P-

and H-coils for reference.

Coil Resistance (reference)

P-coil

0.072ohm at 68° F

H-coil

1.300 ohm at 68° F

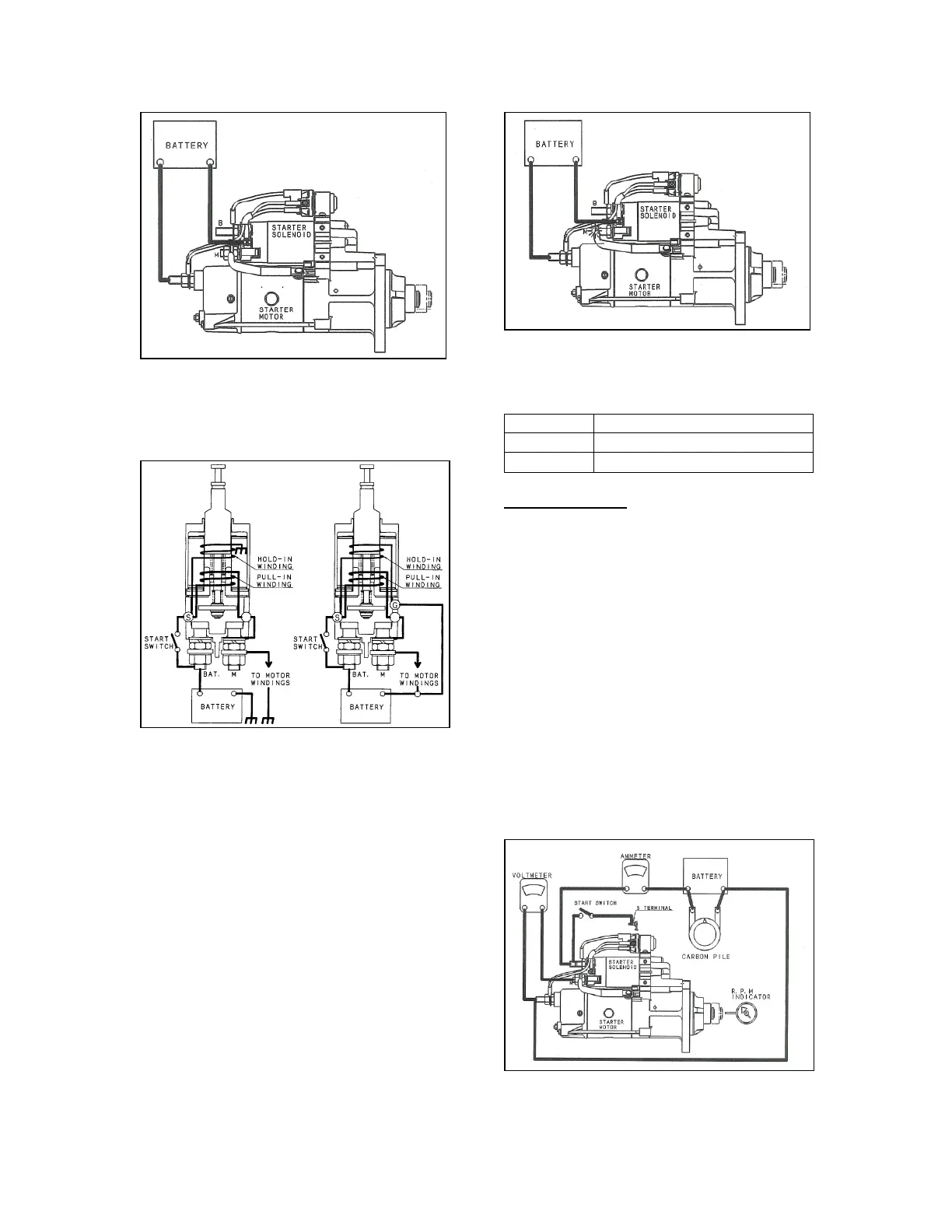

2.5.2 No-load test

The no-load test makes it easy to inspect

the starter for functional failure without

disassembling. This test can also identify an

open/short circuit that is difficult to check

when disassembled.

As shown in figure 7, connect the starter,

fully charged battery, ammeter, and

voltmeter. If possible, connect a resistor

suitable for voltage control in parallel with

the battery. In addition, use an rpm indicator

to measure the revolution speed of the

output shaft.

Note:

Attention should be given to the

output shaft which advances forward to

approximately 0.8" (20 mm) and rotates at

that position when the starter is operated.

Figure 7 - NO-LOAD TEST CIRCUIT (BODY-

GROUND TYPE)

Loading...

Loading...