4

* If the output shaft does not move, stop

voltage application. If voltage continues to

be applied, excessive heat will occur in

the starter solenoid and give thermal

damage to the coil, thereby making it

unserviceable.

Inspect that the current and revolution speed

satisfy the following standards when the

start switch is closed.

Voltage Current Speed

23.5 V 125 A max. 3000 rpm min.

It is not necessary to adjust the voltage to

the exact value of 23.5 V. If the voltage is

slightly higher, the rpm will be

proportionately higher, while if the voltage is

lower, the rpm will be proportionately lower.

The current is independent of the voltage,

and can be judged using the above

standard.

* Note that the starter solenoid will not

operate unless the voltage between the S-

terminal and the ground exceeds 16 V.

Test result and possible cause

1. Rated current draw and revolution speed

indicate normal condition of the starter.

2. Low revolution speed and high current

draw indicate:

a. Too much friction inside starter motor

such as clogging, dirt, wearing, faulty

bearings

b. Shorted circuit inside starter

3. No revolution of the output shaft indicates:

a. Grounded M-lead wire or field coils

b. Frozen bearings

4. No current draw indicates:

a. Open field coils

b. Open armature coils

c. Broken brush springs, worn brushes, or

high insulation resistance between

brushes and commutator

5. Extremely low revolution speed and low

current draw indicate:

Poor connection between M-terminal

and lead wire, or between bracket and

brush holder screws (body-ground type

only), damaged M-lead wire, damaged

brush pig tails, or poor contact between

commutator and brushes

6. High revolution speed and high current

draw indicate:

Shorted field coils

* In case of symptoms 2 to 6, replace the

starter, because of the possible failures

mentioned above.

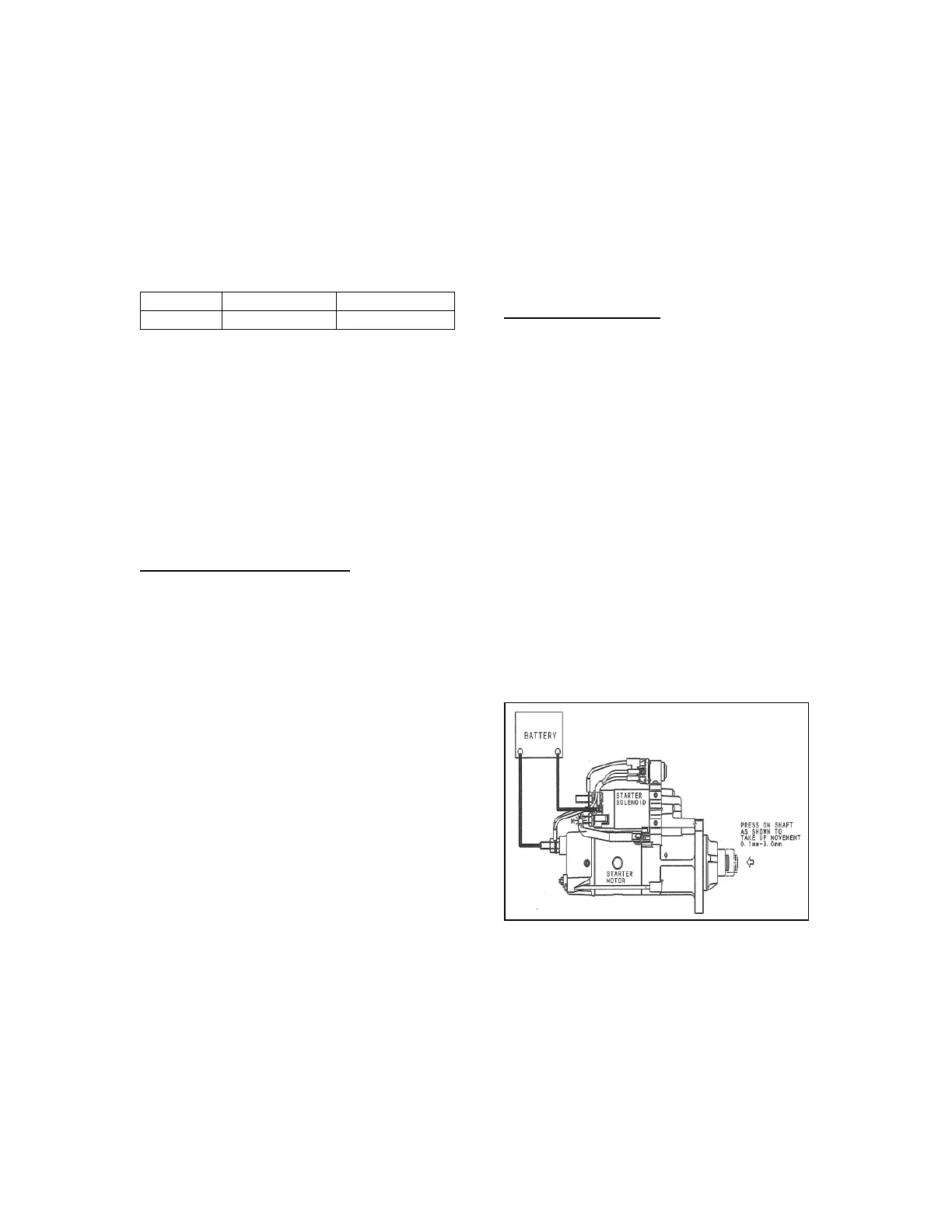

2.5.3 Output shaft play

Before reinstalling the starter to the engine,

follow the procedure below to inspect the

output shaft clearance.

1. Remove the M-terminal nut and keep the

lead wire end in contact with the M-

terminal.

2. Apply voltage to between the S-terminal

and the ground to let the pinion advance

forward. Immediately after that, separate

the lead wire from the M-terminal. The

pinion stays in the advanced forward

position until the battery is disconnected.

3. As described in figure 8, measure the

distance between the shaft pressed-in

and pulled-out positions. The play should

be within 0.004" to 0.118" (0.1 to 3.0

mm). If the measured value does not

satisfy the standard, replace the starter.

Figure 8 - CHECKING OUTPUT SHAFT CLEARANCE

(GROUND-FLOAT TYPE)

Loading...

Loading...