Section 07: TRANSMISSION

PA1562

14

excess grease from the exterior of the clutch

disc hub. It is very important that no

excess grease is left on the exterior of

the clutch hub or clutch disk!

• Install two temporary pilot studs (7/16-14, 3”

long), placing them on the same diameter,

180

o

apart. These are used to aid in the

alignment of the clutch pressure plate.

• Verify that the pilot bearing is seated

properly in the flywheel. Insert a clutch

alignment tool (SAE 2” DIA, 10 Spline)

through the clutch disc and into the pilot

bearing. PLEASE NOTE: the direction

matters – the large side of the hub should

face the clutch pressure plate. The clutch

disc hub should be marked “flywheel side” –

this side should face the flywheel.

• Use the clutch alignment tool to keep the

clutch disc in the proper position and align

the clutch cover with the two studs. Push the

cover in place in the direction of the flywheel

and start installing the clutch bolts. Use

Lock-Tite for each bolt. Install, but do not

torque, the 10 bolts. Remove the two pilot

studs and in their place install the remaining

2 bolts.

• When the bolts are hand tight, be sure that

the clutch cover fits into the flywheel

centering ring. Tighten each bolt a little at a

time, in a crisscross pattern, until the

pressure plate cover contacts the flywheel

face. Once the cover has touched the face

of the flywheel, torque the clutch bolts to 55

ft-lbs, again in a crisscross fashion.

• Remove the clutch alignment tool. If the

installation was successful, it should slide

out smoothly.

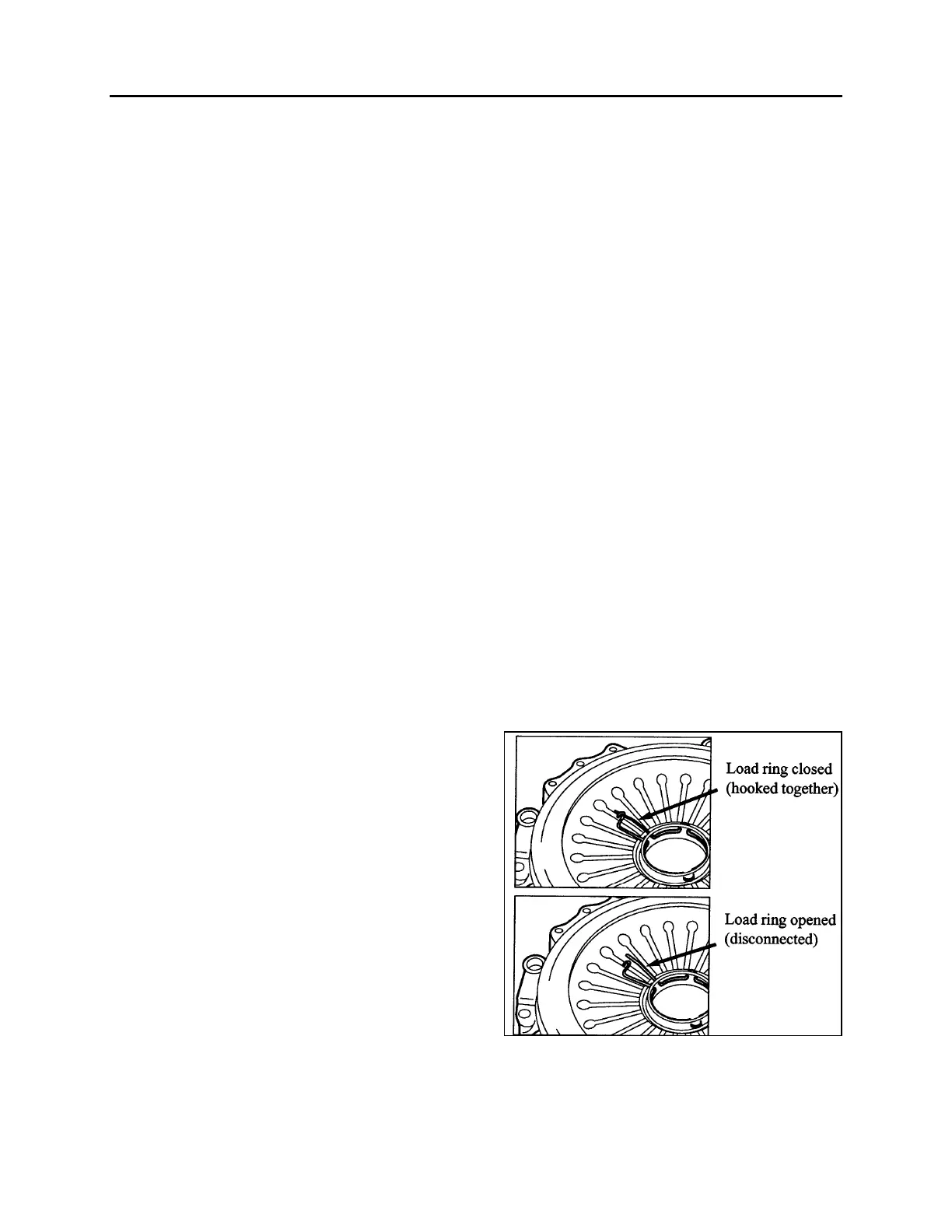

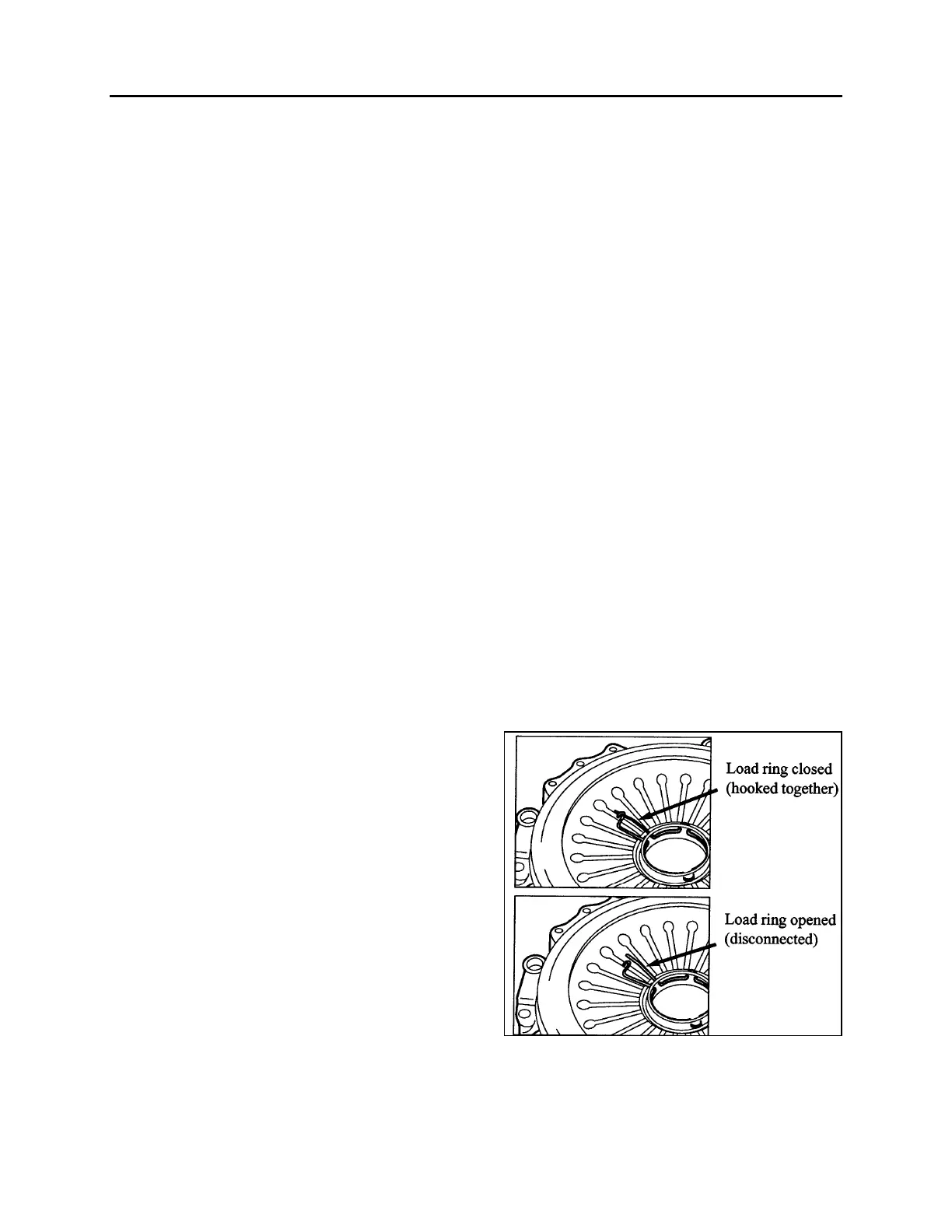

• Ensure that the release bearing retaining

clip (located on the “fingers” of the pressure

plate) is closed. Refer to figure 8.

• Remove the Clutch Inspection Cover from

the bottom of the transmission.

• The transmission should have been shipped

in gear. This will allow the installer to rotate

the output shaft in order to align the input

shaft with the clutch disc hub. If the

transmission is in neutral, a “strap wrench”

(with a rubber or leather strap) can be used

to align the input shaft. Do not use a wrench

of the “chain” variety, as damage to the

input shaft may result. When aligned, push

the transmission towards the engine. Be

sure that the bell housing contacts the

flywheel housing.

Warning!

• Insure that the transmission moves in a

straight line. It can very easily go off center

relative to the clutch disc and pilot bearing.

• Insure that the bell housing interfaces

evenly with the flywheel housing. Even

surface contact should be attained before

tightening bolts.

• Do not try to correct relative position of the

bell housing and flywheel housing by pulling

the transmission into place with the bell

housing bolts. The transmission bell

housing should seat into the flywheel

housing freely.

• When the bell housing and flywheel housing

surfaces and bolt holes are aligned, install

the transmission bolts. Only hardened steel

flat washers should be used, SERRATED

LOCK WASHERS ARE NOT ALLOWED.

Torque the transmission bolts to 55 ft-lbs. in

a crisscross fashion.

• From underneath, push the clutch release

bearing forward (in the direction of flywheel)

using the release fork. Use force to snap the

bearing into the retaining clip located on the

“fingers” of the pressure plate. The installer

should be able to both hear and feel the

bearing seat into place. Refer to figure 8.

FIGURE 8: RELEASE BEARING RETAINING CLIP 07112

• Install the Clutch Actuator inspection cover.

• The clutch/transmission installation is now

complete.

Loading...

Loading...