Section 12: BRAKE AND AIR SYSTEM

PA1562

29

CAUTION

Use only this type of grease on the sensors.

2. Insert spring clip in the holder on hub. Make

sure the spring clip tabs are on the inboard

side of the vehicle. Push in until the clip

stops.

3. Push the sensor completely inside the

spring clip until it is in contact with the tooth

wheel. Ensure mounting is rigid, as it is an

important criterion for adequate sensor

operation.

NOTE

This installation should be of the "press fit"

type.

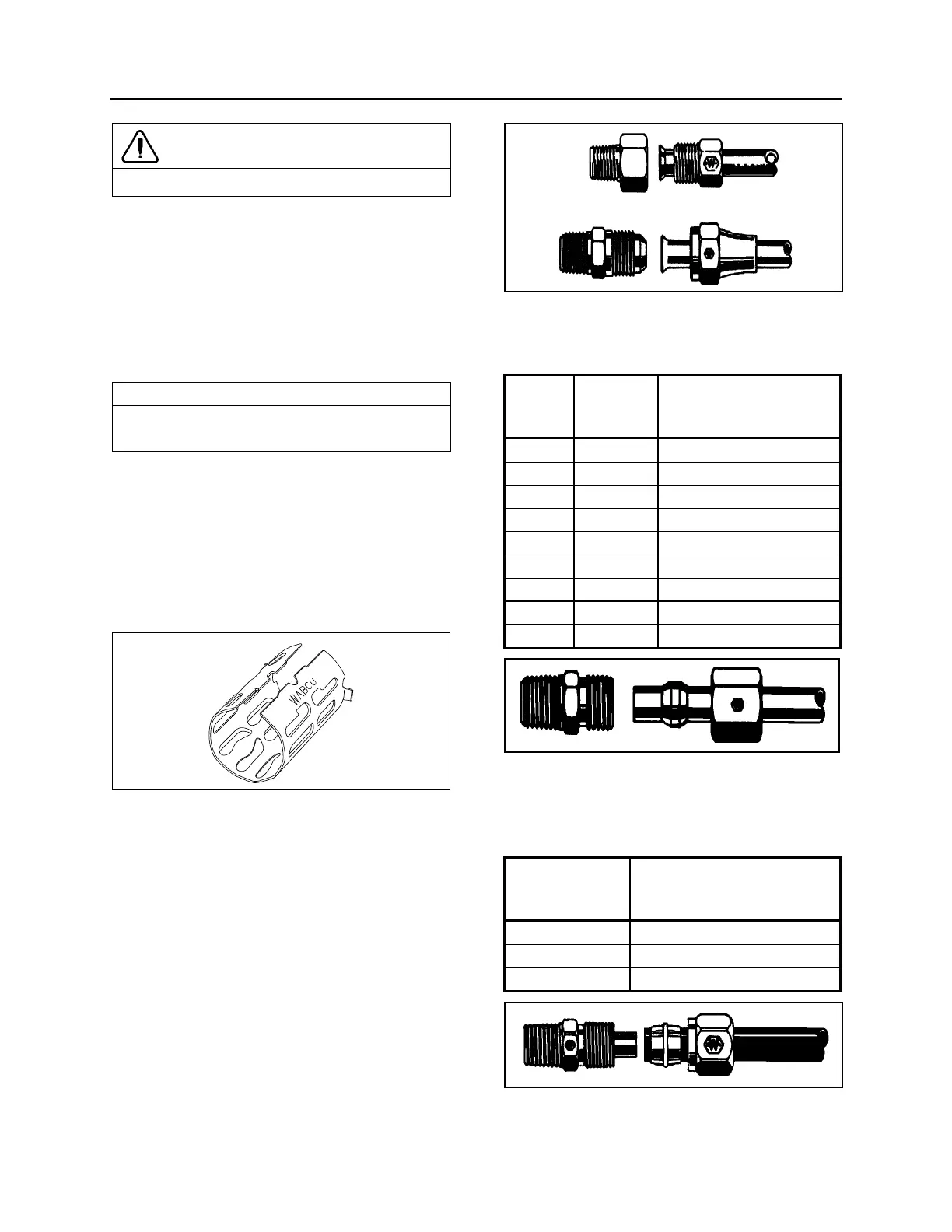

31.3.4 Spring clip

The spring clip retains the sensor in its mounting

bracket close to the toothed pulse wheel. The

gap between the sensor end and teeth is set

automatically by pushing the sensor in the clip

hard up against the tooth wheel, and the latter

knocks back the sensor to its adjusted position

(Fig. 47).

FIGURE 47: SPRING CLIP 12161

Maintenance

The spring clip requires no specific maintnance.

32. FITTING TIGHTENING TORQUES

45

ο

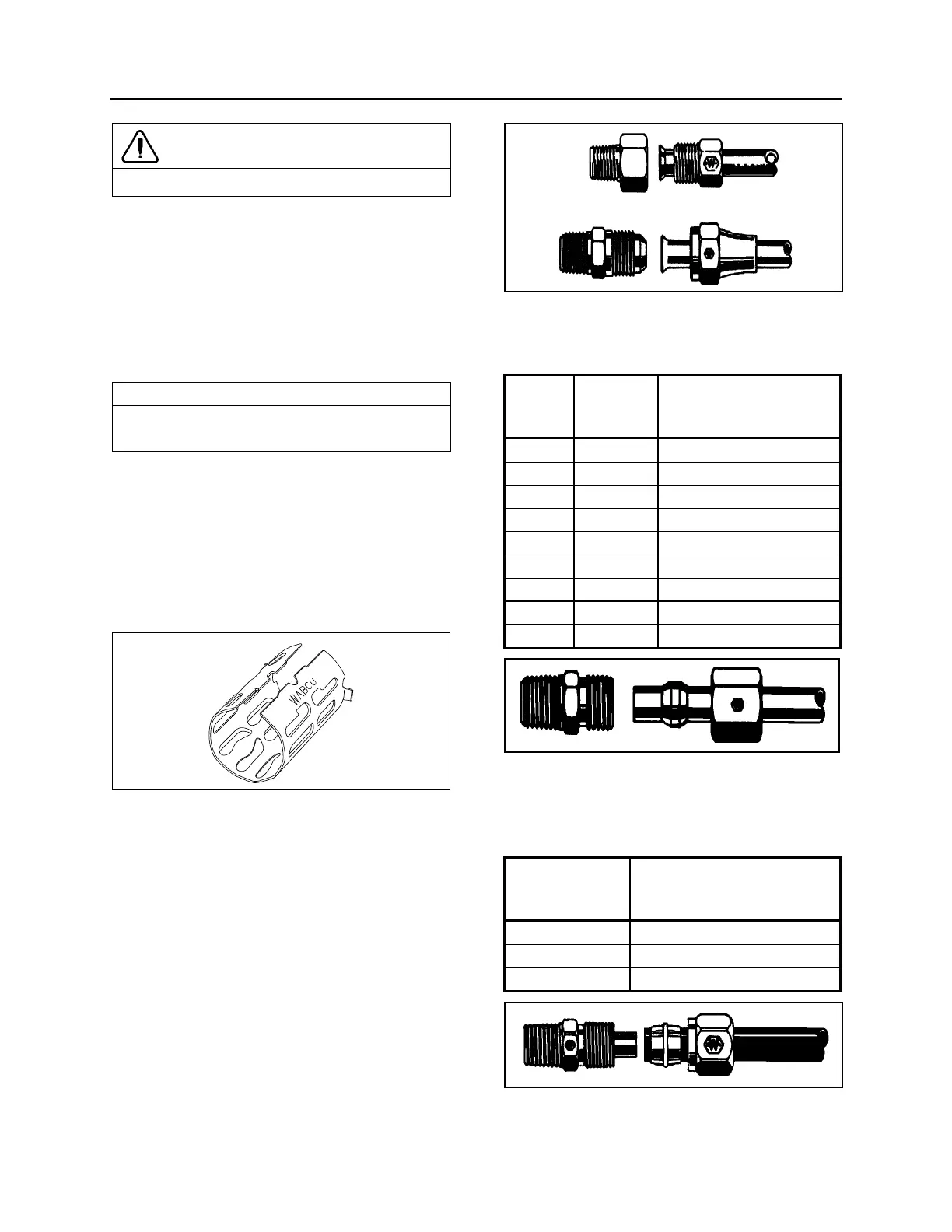

Flare and Inverted Flare: Tighten assembly

with a wrench until a solid feeling is encoun-

tered. From that point, tighten 1/6 turn (Fig. 48).

FIGURE 48: HOSE FITTINGS 12053

Compression: Tighten nut by hand (Fig. 49).

From that point, tighten using a wrench the

number of turns indicated in the chart hereafter.

Fitting

size

Pipe

diameter

(inches)

Number of additional

turns required following

hand tightening

2 1/8 1 ¼

3 3/16 1 ¼

4 1/4 1 ¼

5 5/16 1 ¾

6 3/8 2 ¼

8 1/2 2 ¼

10 5/8 2 ¼

12 3/4 2 ¼

16 1 2 ¼

FIGURE 49: HOSE FITTING 12054

NTA-Type Plastic Tubing: Hand tighten nut

(Fig. 50). From that point, tighten using a wrench

the number of turns indicated in the following

chart.

Tubing diameter

(inches)

Number of additional turns

required following hand

tightening

1/4 3

3/8 to 1/2 4

5/8 to 3/4 3 ½

FIGURE 50: HOSE FITTING 12055

Loading...

Loading...