Section 1

Introduction

Copyright 2002 Maintenance Manual MM-0204

Page 2 ArvinMeritor, Inc. Issued 08-02

Operation

The compressor is driven by the engine. The

compressor’s crankshaft turns continuously while

the engine is running. Compression of air is

controlled by the

governor

and by the

compressor’s unloading mechanisms

.

The

governor

maintains the brake system air

pressure at preset maximum and minimum levels.

The governor is mounted apart from the

compressor, either horizontally or vertically. The

governor port is located on the crankcase of the

compressor.

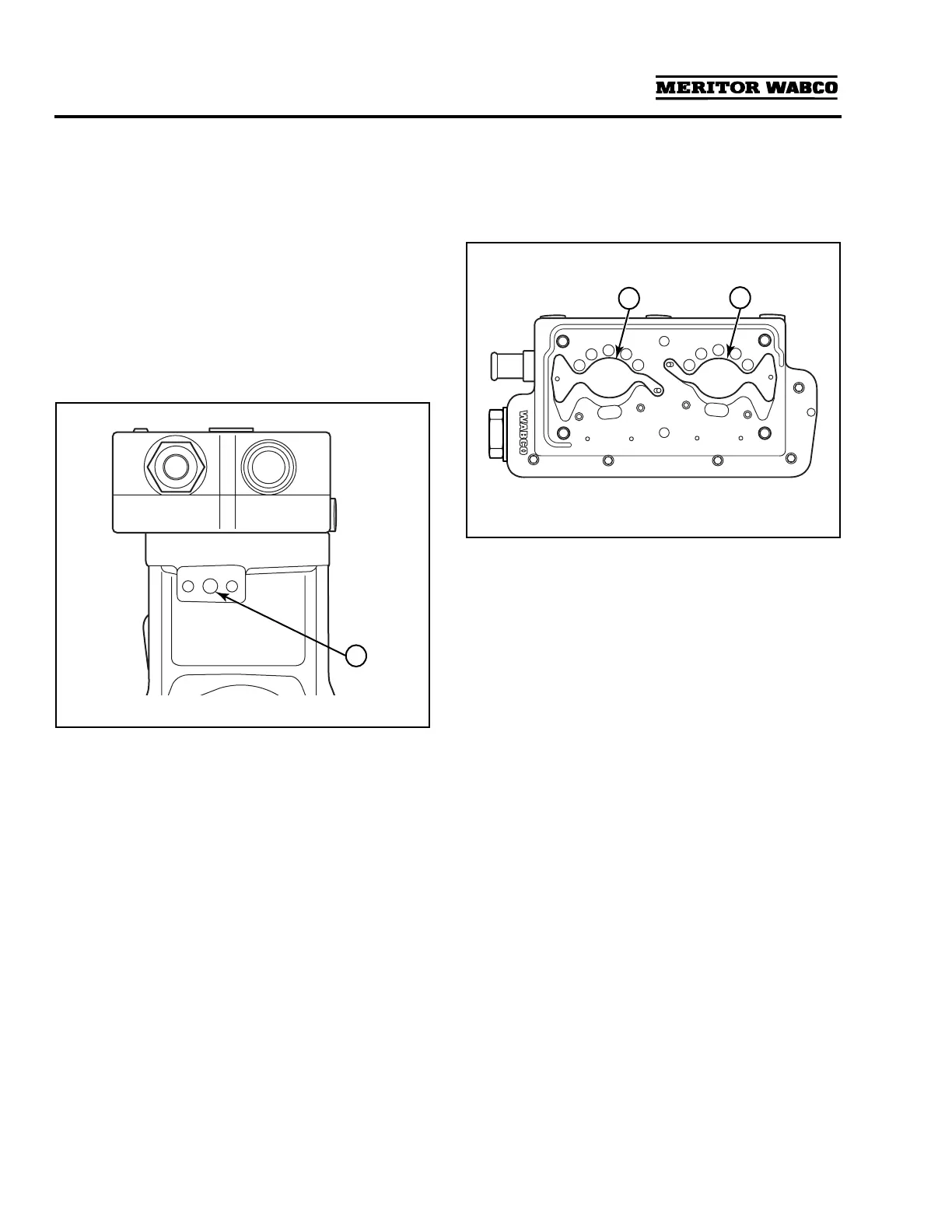

Figure 1.3

.

The

unloader mechanisms

control the air

compression cycle; an air compression cycle has

three phases:

1.

Induction:

Air flows from the engine to the

compressor, opening the inlet valves in the

cylinder head of the compressor.

2.

Compression:

Air pressure is increased,

causing the compressor’s discharge valves to

open.

3.

Unloading:

Air passes from the cylinders to

the inlet chambers of the cylinder head via a

port controlled by sliding leaf valves.

When system cut-in pressure is reached, air is

exhausted from the unloader ports.

4. After unloading, the unloader pistons return

the sliding leaf valves to the loaded position.

This seals the unloader ports and compression

resumes.

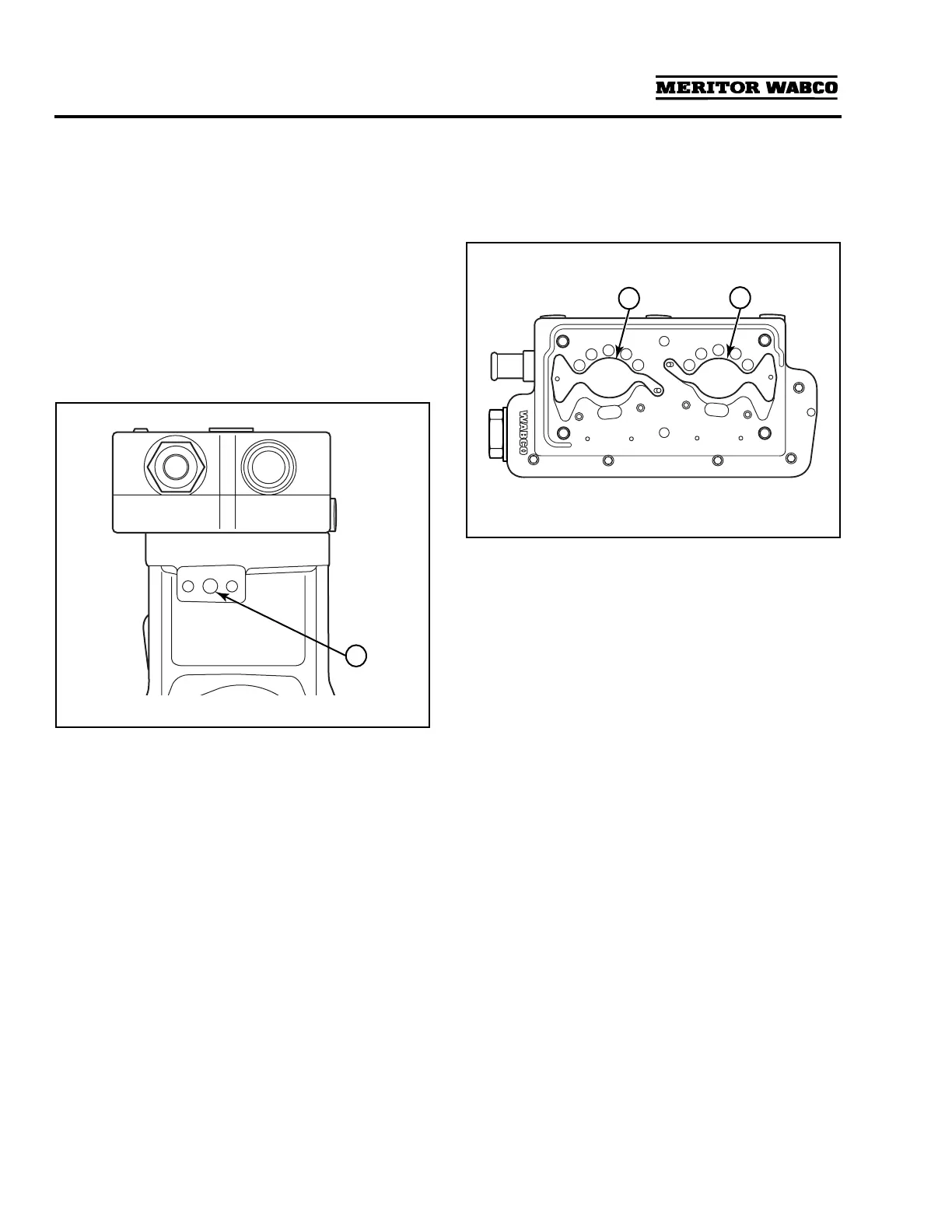

Figure 1.4

.

Maintenance Intervals

The Meritor WABCO System Saver 636 twin

cylinder air compressor receives inlet air, oil and

coolant from the engine, so it is important to

follow the engine manufacturer’s

recommendations and maintenance schedules

regarding fluid levels, air filter and recommended

change intervals.

Cylinder Head

Remove carbon deposits from the discharge cavity

and rust and scale from the cooling passages of

the cylinder head.

Clean carbon and dirt from the inlet and unloader

passages.

Figure 1.3

1 GOVERNOR PORT

4000265b

1

Figure 1.4

1 SLIDING LEAF VALVES

4000266c

1

1

Loading...

Loading...