Section 01: ENGINE

PA1562

46

close to yoke. On right side: close to the

solenoid valve of the output retarder.

33. From under the vehicle, disconnect the

propeller shaft as detailed in Section 09,

under heading "Propeller Shaft Removal".

34. Inspect the power plant assembly to ensure

that nothing will interfere when sliding out

the cradle. Check for connections or hoses

not mentioned in this list as some vehicles

are equipped with special or aftermarket

components.

35. Remove the six retaining bolts, washers and

nuts securing the power plant cradle to the

vehicle rear subframe (Fig. 25).

NOTE

Check if any spacer(s) have been installed

between power plant cradle and vehicle rear

subframe, and if so, note position of each

washer for reinstallation purposes.

36. Using a suitable equipment, with a minimum

capacity of 4,000 lbs (1 800 kg), slightly

raise the power plant cradle.

37. Pull engine out slowly from the engine

compartment. Make sure all lines, wiring

and accessories are disconnected and are

not tangled.

CAUTION

Due to the minimum clearance between the

power plant equipment and the top of the

engine compartment, extreme care should be

used to raise the power plant cradle, just

enough to free the cradle. Clearance between

power plant cradle and mounting rail should

range between ¼" and ½" (6-12 mm).

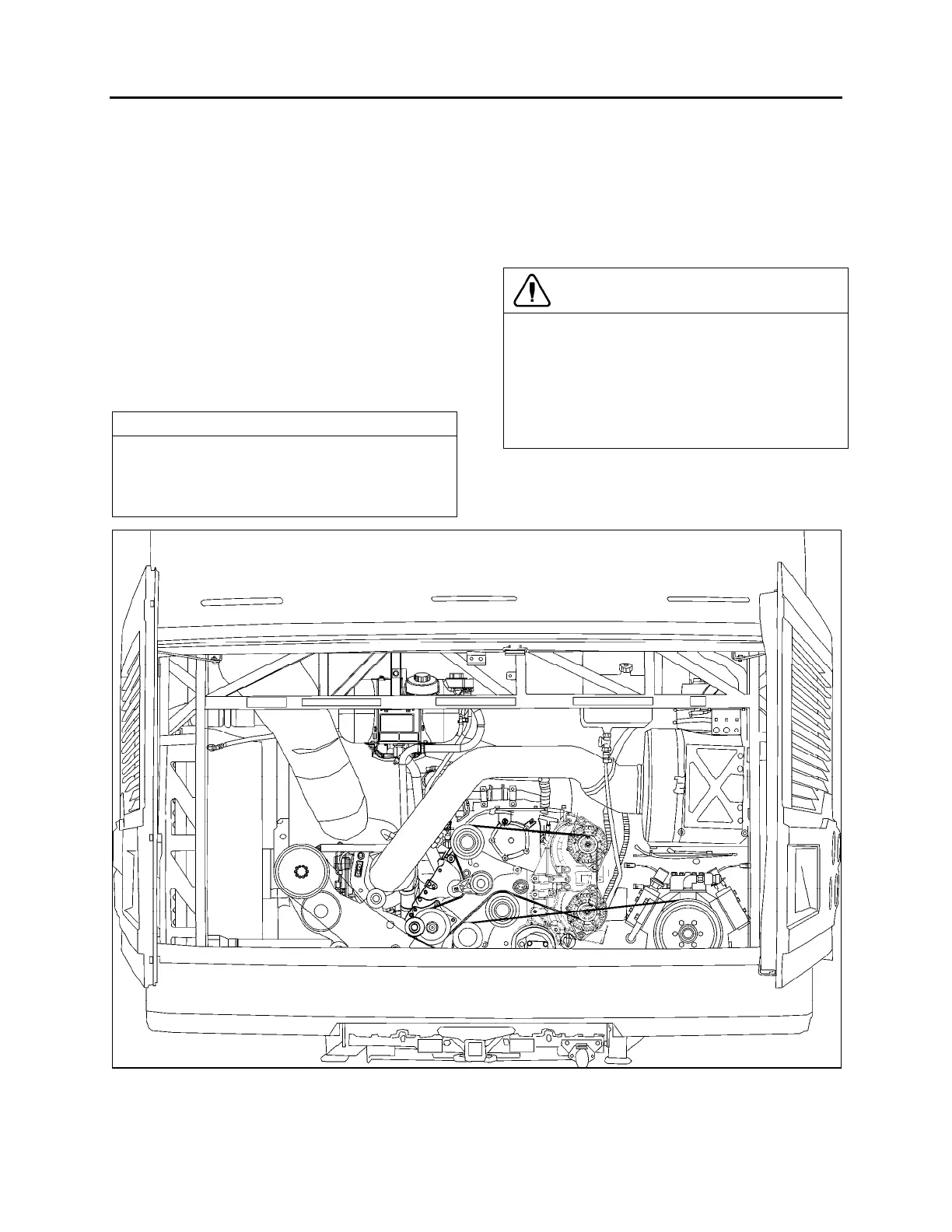

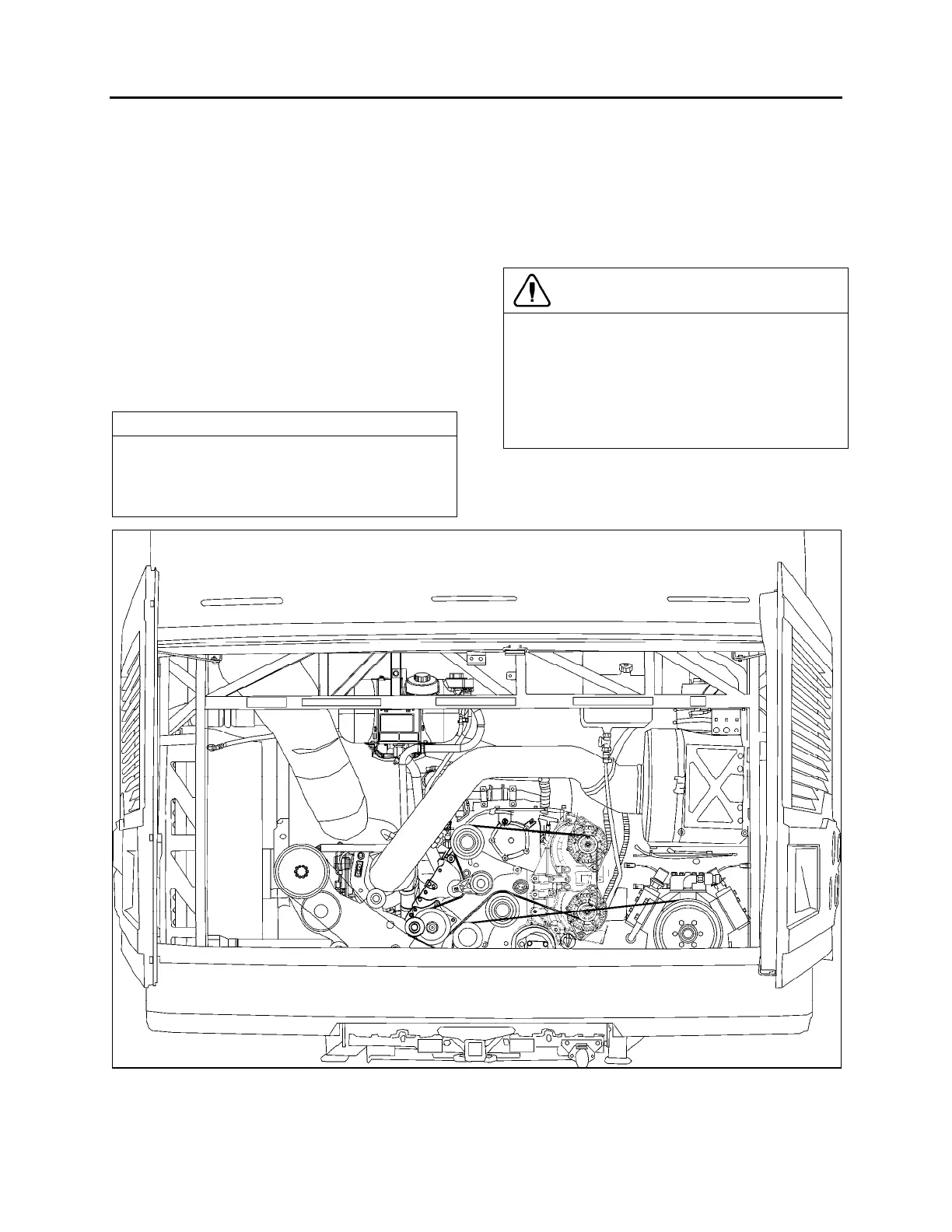

FIGURE 24: ENGINE COMPARTMENT X3 COACHES (TYPICAL) 01184_A

Loading...

Loading...