Replacing and Setting the Switch (222) and the

potentiometer (232)

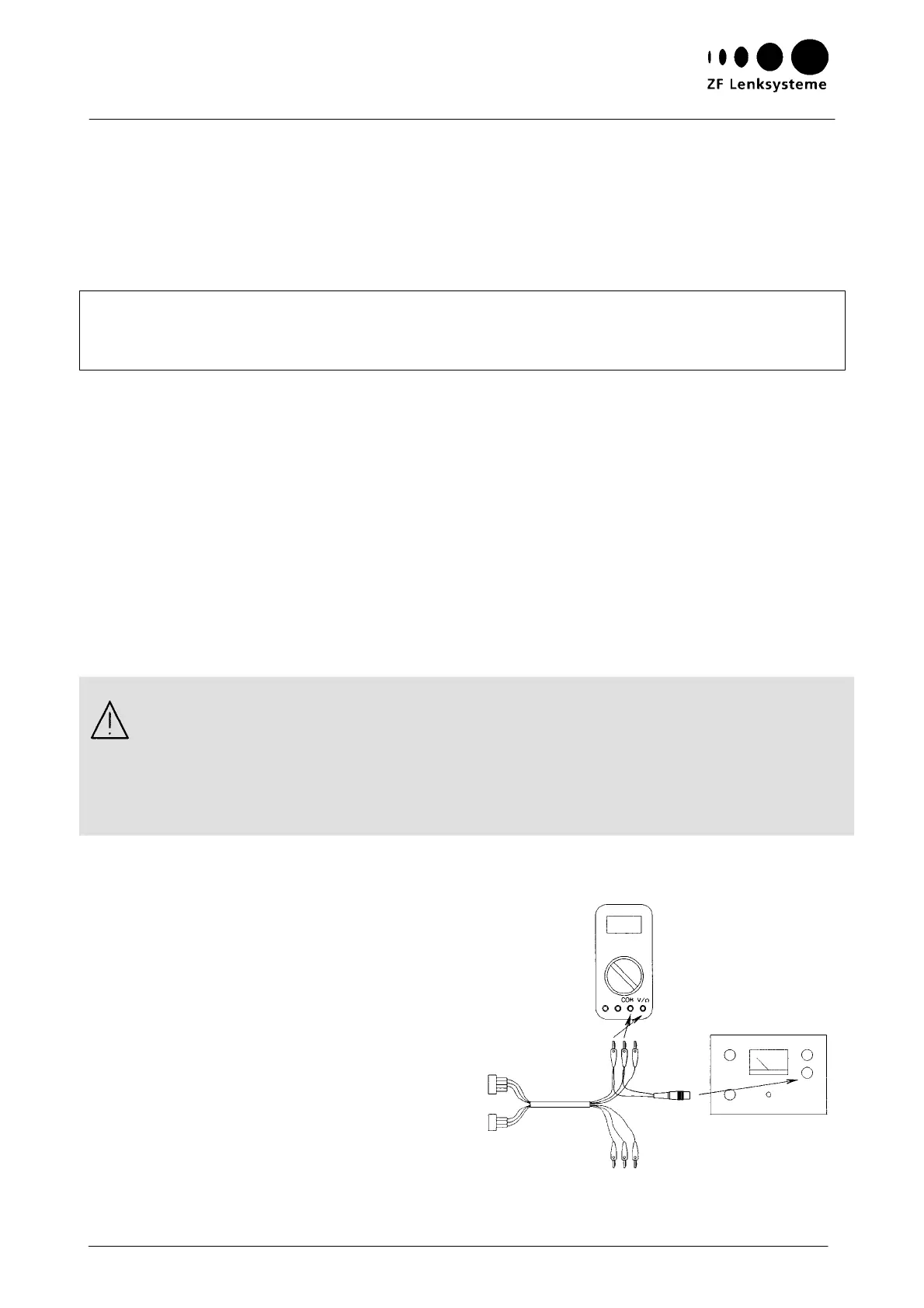

Fig. 19

Tool [6]

Cable colour

black

Cable colour

white

red

blue

red

blue

g

reen

green

Tool [7]

5 V

24 Instructions on Design, Operation, Maintenance and Inspection

2.2 Fitting the potentiometer (232) again

C

heck whether the steering gear is in mid-position.

Fit an O ring (232.1) to the potentiometer (232).

Place the deep groove of the potentiometer (232) drive on the carrier (230).

Note:

The slider of the potentiometer (232) being spring-loaded, it will return to its initial position when

disassembled.

Therefore, check whether the potentiometer (232) can be turned through 50

°

minimum to either

si

de when the steering gear is in mid-position.

Fasten the potentiometer (232) along with the spacing sleeves (233), the screening plate (234)

and the cap screws (235).

Tightening torque: 2.8 Nm

Check:

The installed position of the potentiometer (232) must be identical with the position as marked

during disassembly.

2.3 Setting the potentiometer (232)

Attention:

A maximum value of 6 V must not be exceeded for otherwise the potentiometer (232) would be

destroyed.

The tumbler switch of the Servotronictest tester (tool [7]) must not be switched to speedo position

as otherwise the potentiometer would be destroyed.

Rotate the steering gear to mid-position (dividing the total number of steering wheel turns in two).

Setting a voltage of 5V

Connect tools [6] and [7] (or use a suitable

transformer) and the Multimeter measuring

instrument as shown in Fig. 19 .

Switch the tumbler switch of the Servotronic-

test tester (tool [7]) to transducer position.

Continue adjusting the transducer regulator

until the Multimeter measuring instrument

reads 5V.

Loading...

Loading...