Function Variants Filling Scale

This items reflects a typical operating sequence of a Filling Scale.

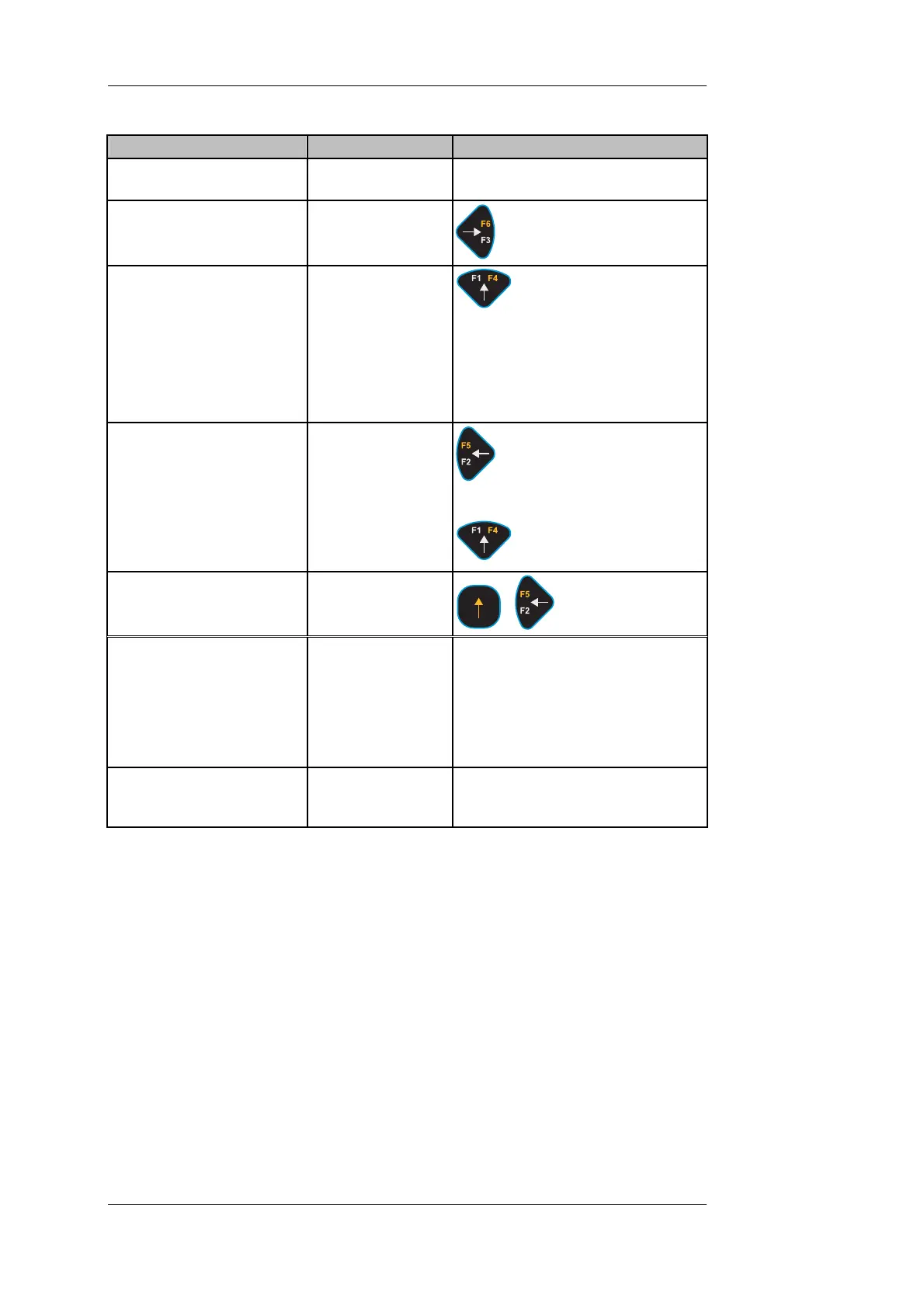

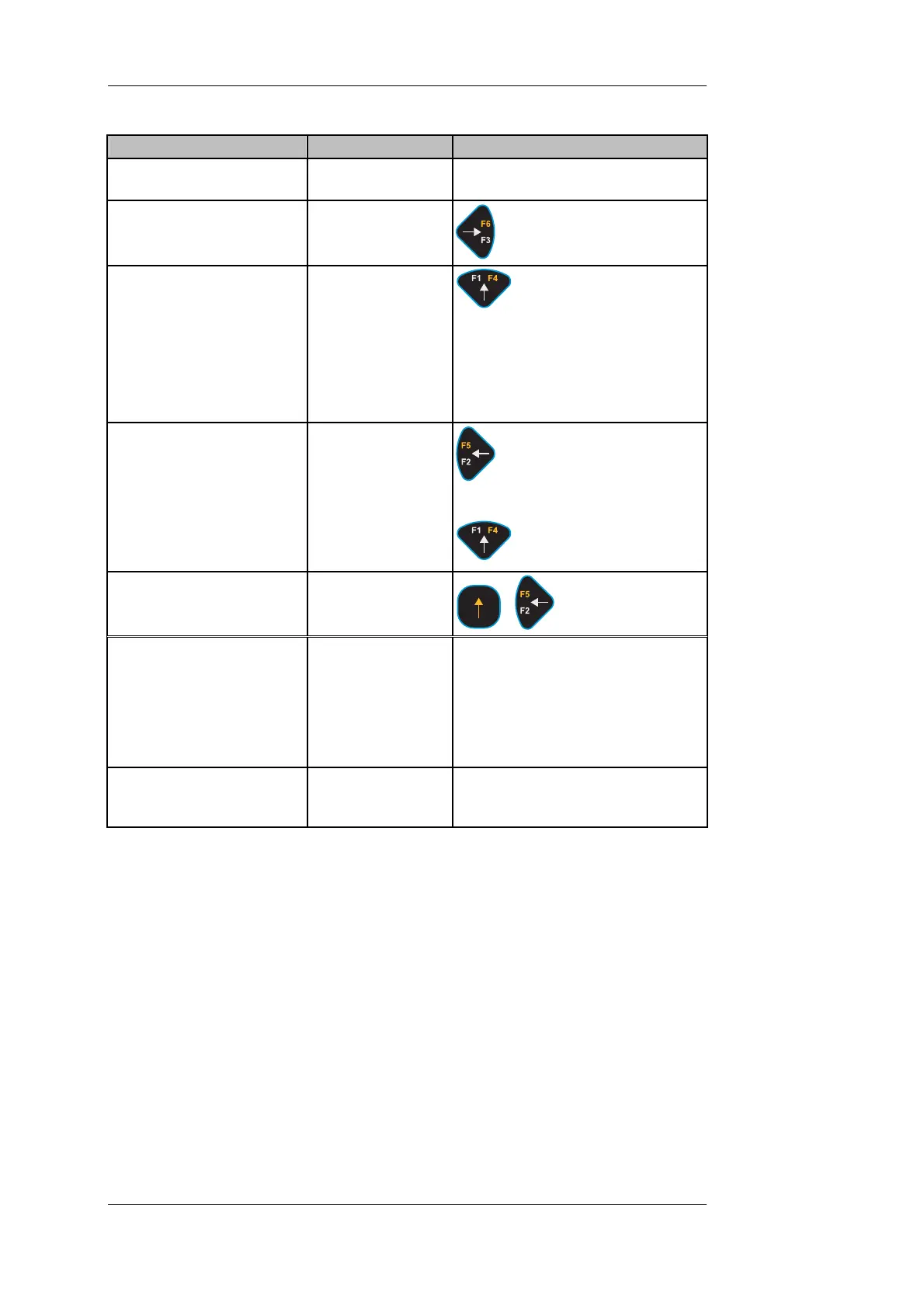

Action

Display (e.g.) Key(s); Comments

1. DISOMAT must be in

home position!

G 3.5 kg

2. Select material type and

enter setpoint.

'MatSet' key

3. Start filling

apr. 1sec.

0.0 kg

G 3.5 kg

Net T

'Start' key

Scale waits for n

automatically.

Scale is tared.

Filling continues auto

o-motion and tares

matically until

s ached. etpoint is re

4. If required, stop filling.

lashes for 20 sec.)

filled

W4004:Filling

Stopped

(f

Net T 55.5 kg

weight already

'Stop' key

Continue filling with

'Start' key

5. If required, abort filling. illing

Aborted

W4104:F

+

'Abort' key

6. Terminate filling. T 59.0 kg

g operation can start after

Net Filled weight and filling operation

are balanced and printed. Weighing

is complete.

Filled weight is displayed for a set

timeout; then, GROSS is displayed.

Next fillin

timeout.

7. Discharge hopper -

per is automatically

discharged.

If filled weight exceeds MAX value

-> weigh hop

Alternatively, you can also

•

terial is to be filled. In this case, the taring

operation before filling is omitted.

perform a mere GROSS weighing. This function is used, if a hopper

containing a residual amount of ma

BV-H2313 GB 0630 DISOMAT

®

Opus – Operating Manual

- 98 - © Schenck Process GmbH, Darmstadt

Loading...

Loading...