Setting Mode Setting Using Calibration Password

5.4.7 Legal-For-Trade Identification, Sealing Locations and

Type

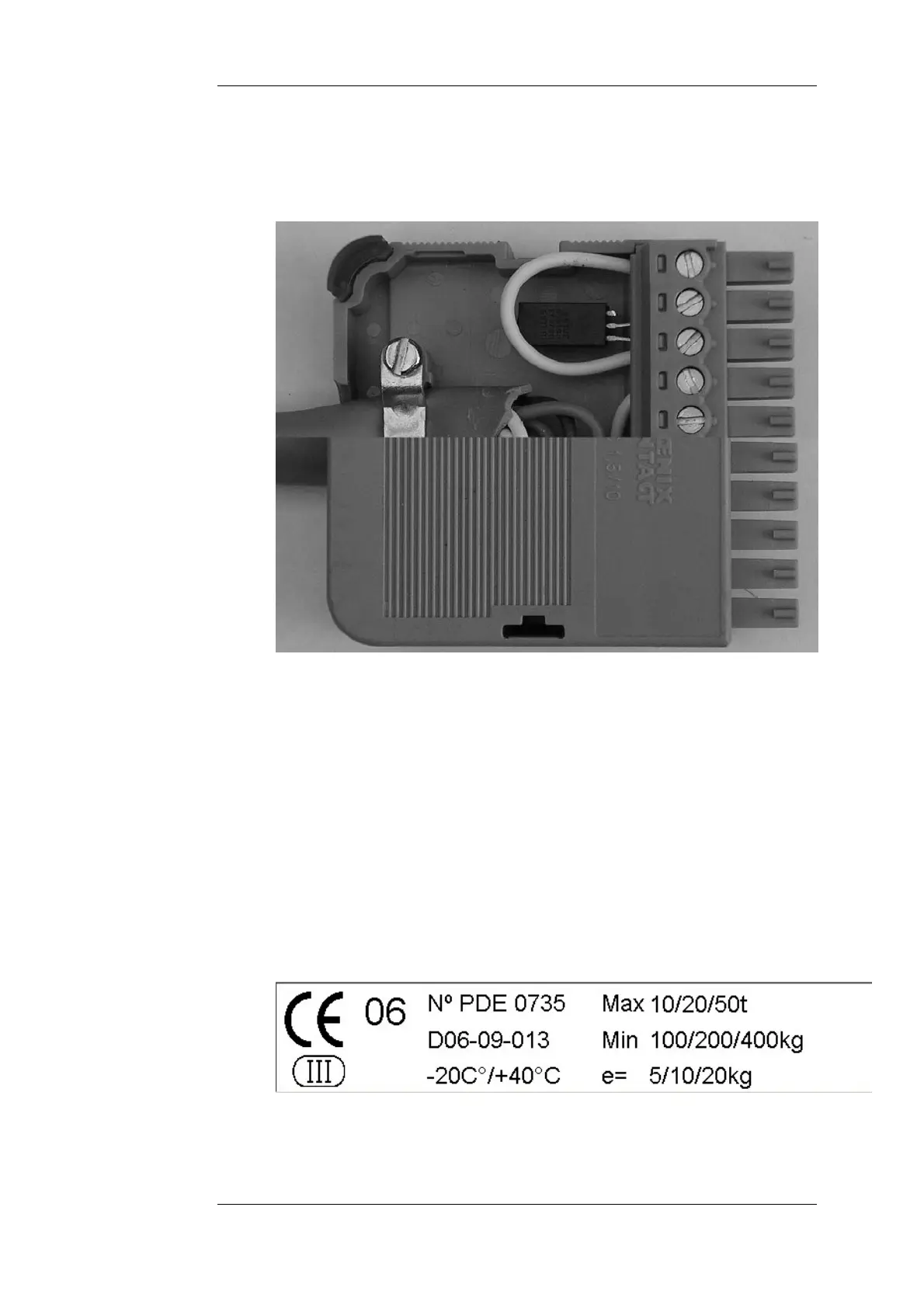

1. After completing adjustment, insert the write lockout jumper in the load cell

dongle (contacts 1-3; see the photograph):

2. The dongle is locked and protected via an adhesive label.

3. The scale casing is protected without locking.

4. A verification plate is placed on the outside of the casing (preferably on the

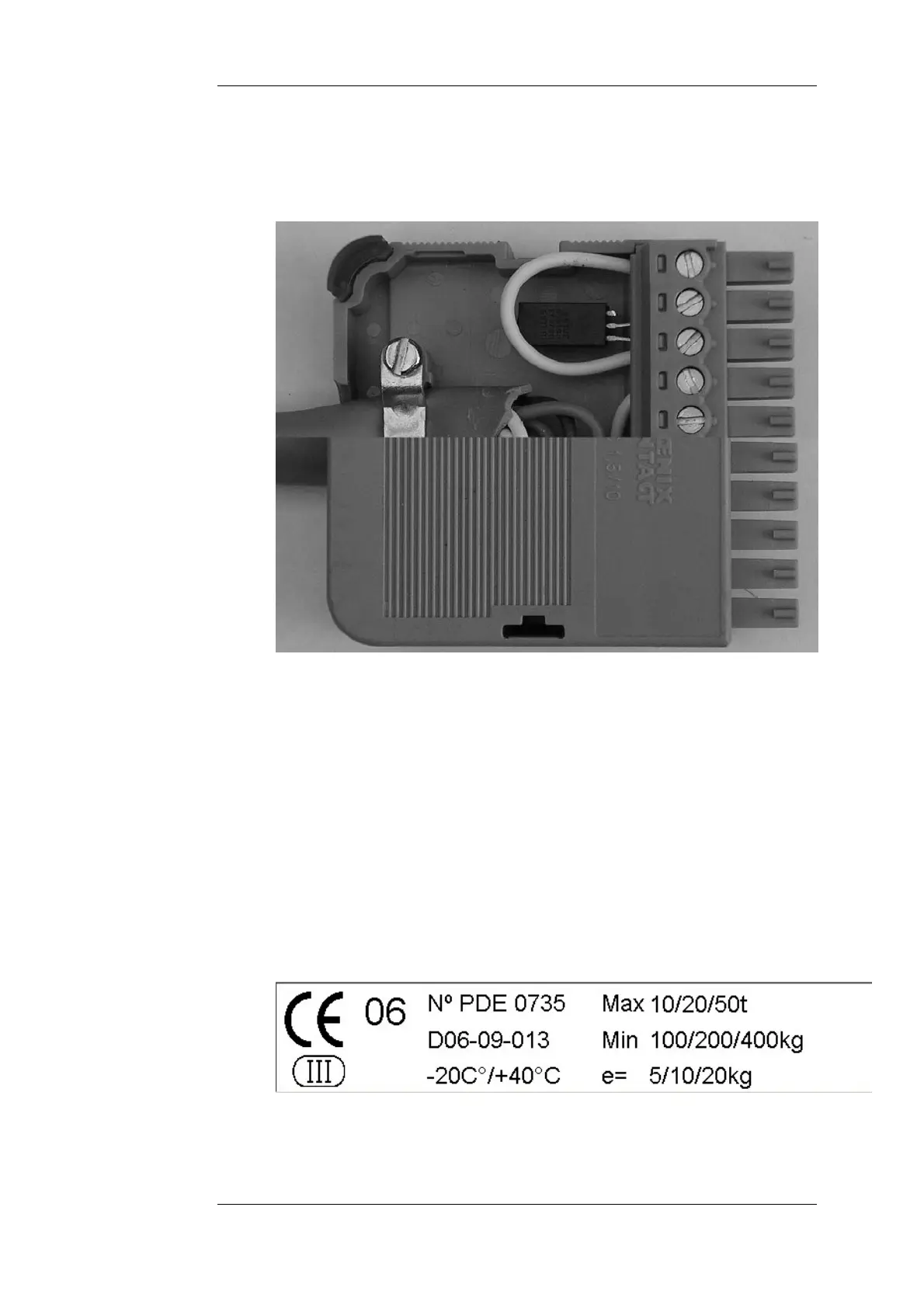

front side above the keyboard) with the data below:

Min Minimum Load

Max Maximum Load

e Resolution

III or IIII Scale Accuracy Class

D06-09-xx No. of EC Type Approval

CEyy with yy = Year of Initial Verification, last 2 figures (06->2006)

The easiest way to make a varification plate is with Schenck's DISOFORM software.

The picture below shows a sample print-out:

If the verification plate is not made of material that is destroyed when detached, it has

cation stamp (the green M) is also applied.

to be protected by an adhesive label.

5. The EC verifi

DISOMAT

®

Opus – Operating Manual 0630 BV-H2313 GB

© Schenck Process GmbH, Darmstadt - 91 -

Loading...

Loading...