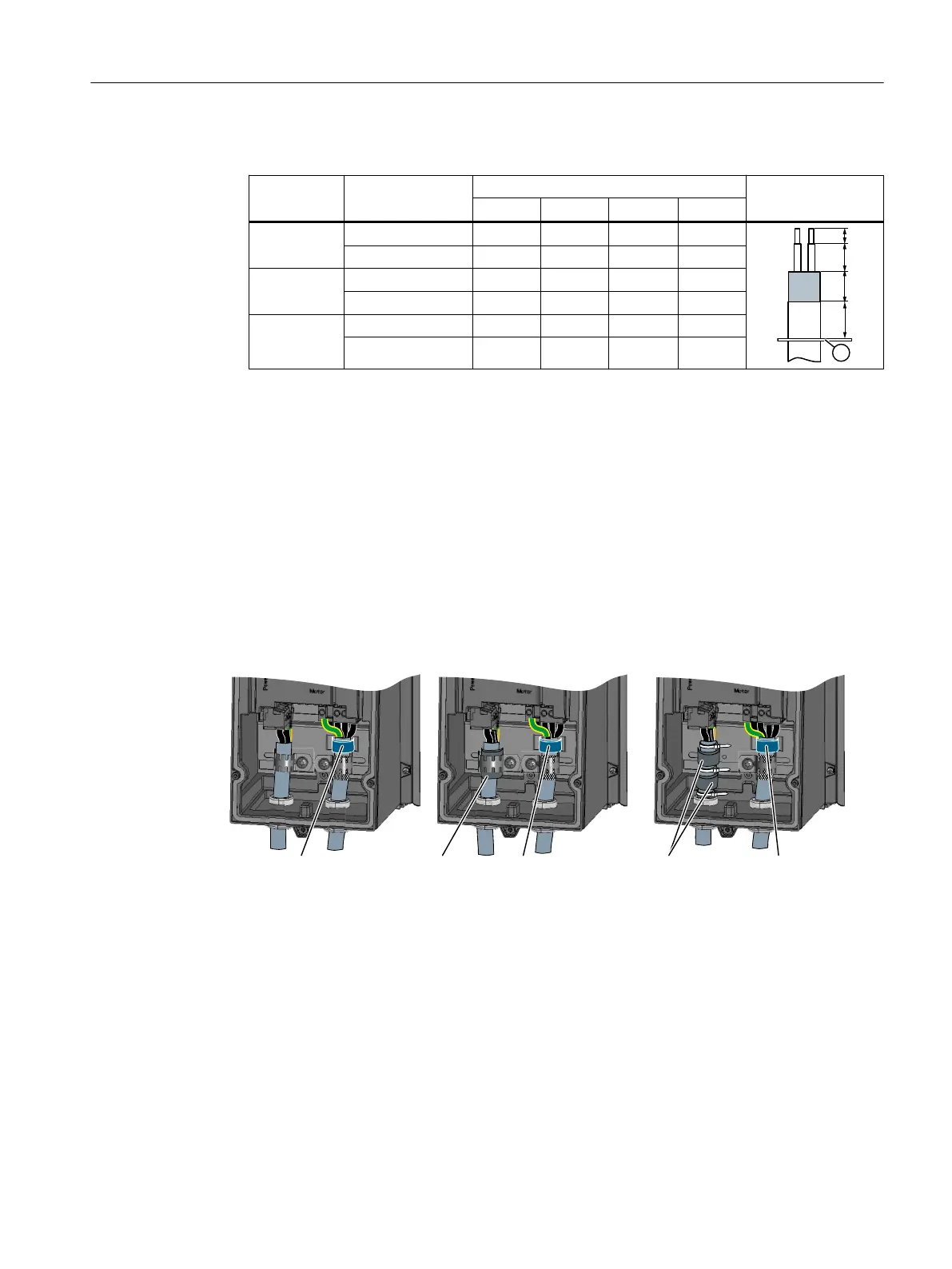

3. Prepare the mains and motor cables for connection in accordance with the table below.

Inverter Connection Dimensions Explanation

A B C

1)

D

FSA Mains cable 10 mm 60 mm - 90 mm

Motor cable 10 mm 60 mm 10 mm 60 mm

FSB Mains cable 10 mm 60 mm - 50 mm

Motor cable 10 mm 50 mm 10 mm 40 mm

FSC Mains cable 10 mm 50 mm - 70 mm

Motor cable 10 mm 50 mm 10 mm 40 mm

1)

Cable shield

① Bolting plate

4. Assemble the cable glands with the prepared cables and EMC cable glands for the control

cables.

5. Seal any unused bushings with a rubber sleeve.

6. Secure the bolting plate to the inverter enclosure. Tightening torque: 2 Nm

Make sure that the seal of the bolting plate is not damaged.

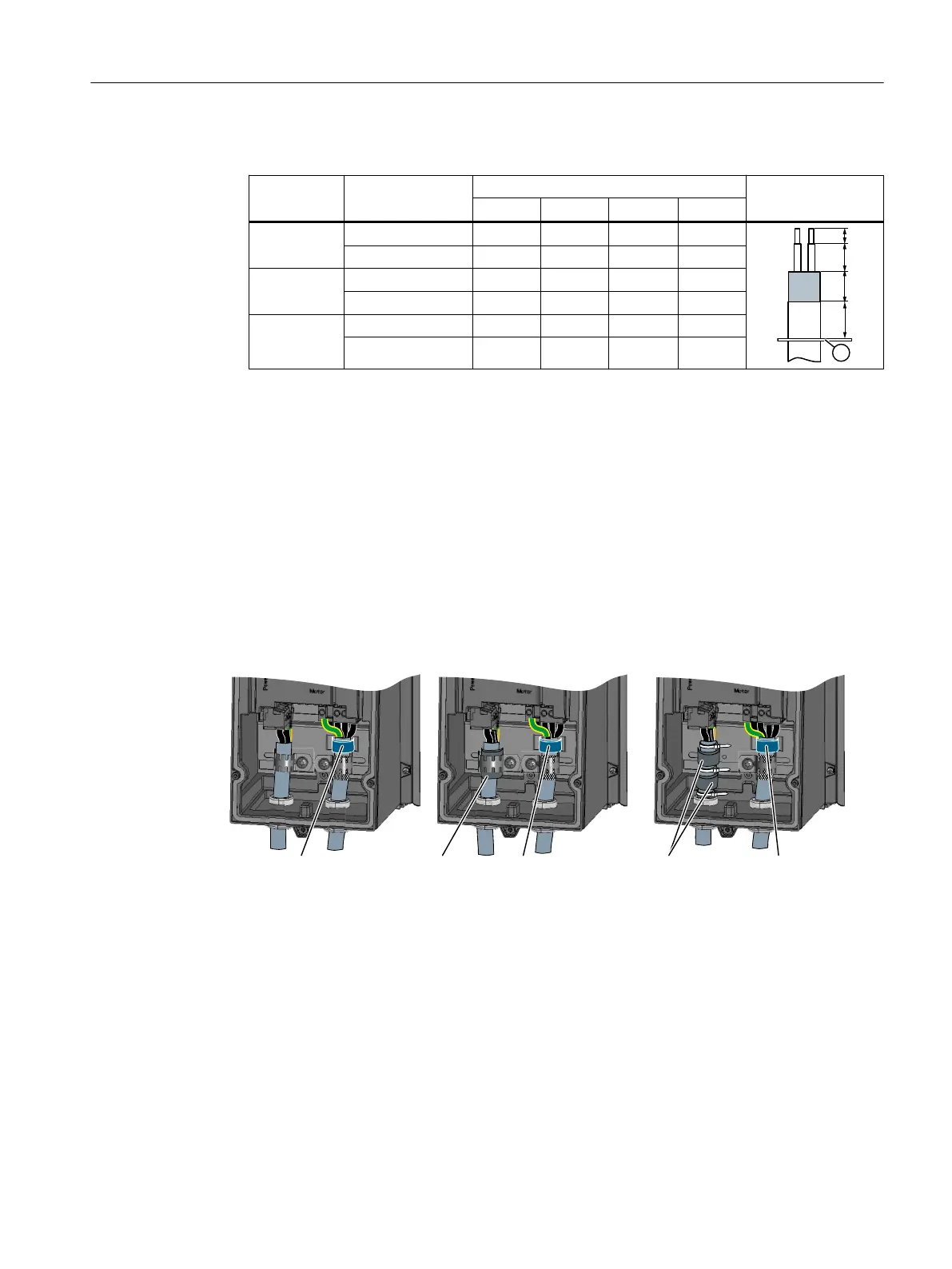

7. Where necessary, fit the supplied ferrite ring onto the motor cable.

Ferrite rings are required to be able to comply with the limit values of IEC 61800-3, Category

C1 with reference to grid-bound interference voltages when using Power Modules with

integrated line filters.

If you use cables > 25 m, the requirements of Category C1 are no longer satisfied.

JUD\IHUULWHULQJV

IRUWKHOLQHFDEOH

%OXHIHUULWHULQJIRU

WKHPRWRUFDEOH

%OXHIHUULWHULQJIRU

WKHPRWRUFDEOH

%OXHIHUULWHULQJIRU

WKHPRWRUFDEOH

JUD\IHUULWHULQJ

IRUWKHOLQHFDEOH

)6&)6$)6%

Figure 4-14 Ferrite rings for the mains and motor cables

Installing

4.4 Connecting the line supply and motor

Converter with the CU230P-2 Control Units

Operating Instructions, 09/2017, FW V4.7 SP9, A5E34257946B AE 91

Loading...

Loading...