Function Manual

100 01/2017

● Number of workpieces specified by the user:

$AC_SPECIAL_PARTS

This counter allows users to make a workpiece counting in accordance with their own definition. Alarm output can be

defined for the case of identity with $AC_REQUIRED_PARTS (workpiece target). Users must reset the counter

themselves.

The first output of the M command for counting after resetting the counter applies as start point. This M command is set in

MD27880 PART_COUNTER or MD27882 PART_COUNTER_MCODE for the relevant counter.

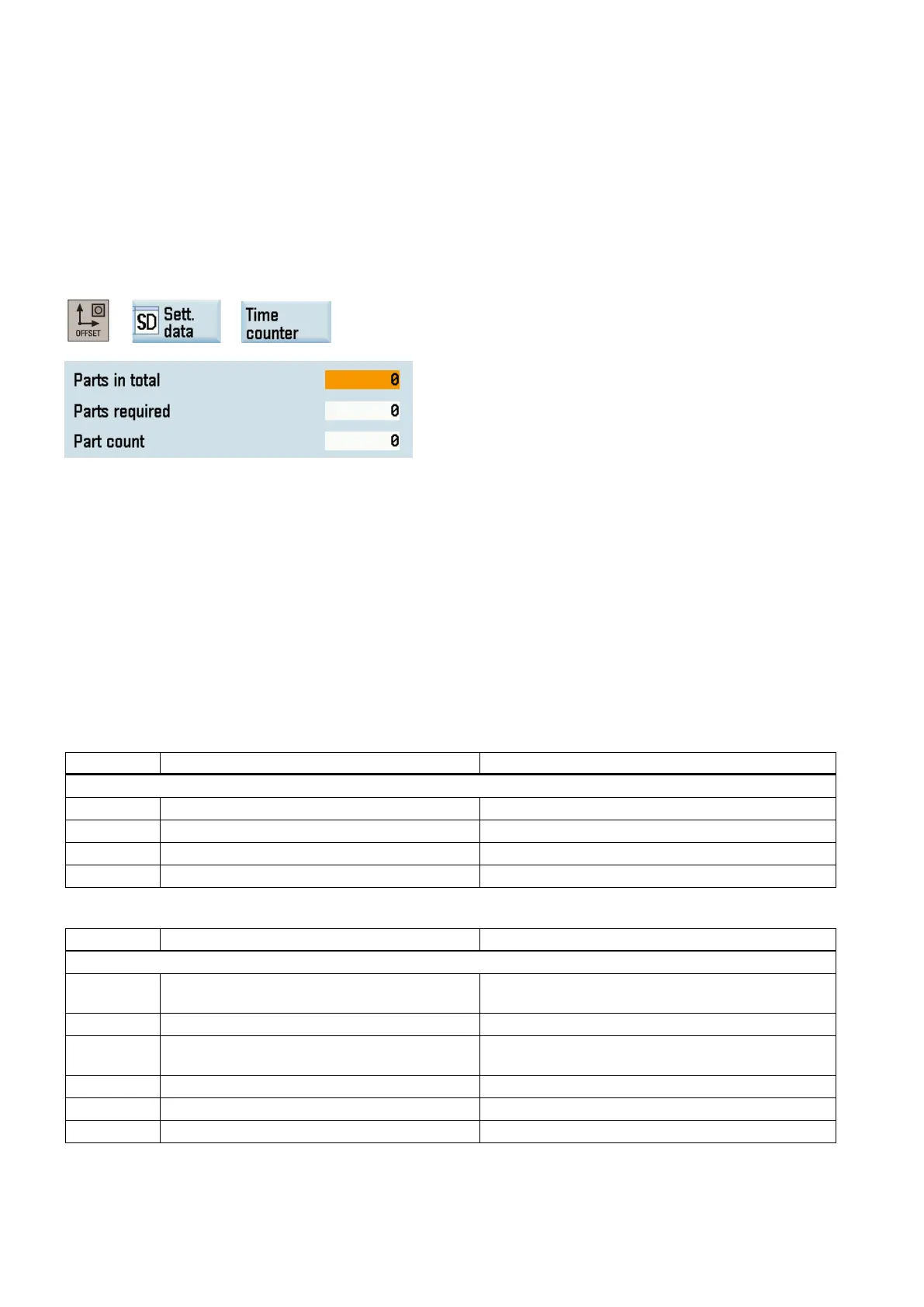

The contents of the counters are visible on the screen after you perform the following operations:

-> -> ->

●

= $AC_TOTAL_PARTS

●

= $AC_REQUIRED_PARTS

●

= $AC_ACTUAL_PARTS

($AC_SPECIAL_PARTS not available for display)

"Part count" is also visible in the information line of the "AUTO" window of the machining operating area.

SINUMERIK 808D/SINUMERIK 808D ADVANCED Programming and Operating Manual

Machine data

NC-specific machine data

10702 IGNORE_SINGLEBLOCK_MASK Prevent single-block stop

Block search parameter settings

Ignore stop conditions for ASUP

Priorities for ASUP_START_MASK

Basic machine data of the channel

20050 AXCONF_GEOAX_ASSIGN_TAB[n] Assignment between geometry axis and channel axis

Geometry axis name in channel [GEOaxis no.]: 0...2

20070 AXCONF_MACHAX_USED[n] Machine axis number valid in channel [channel axis

AXCONF_CHANAX_NAME_TAB[n]

Channel axis name in channel [channel axis no.]: 0...4

Geometry axis with transverse axis function

PROG_EVENT_IGN_SINGLEBLOCK

Prog events ignore the single block

Loading...

Loading...