Function Manual

118 01/2017

Commissioning

Circularity test

It is recommended that the circularity test be used for the commissioning of the friction compensation with constant injected

value, as described above. The commissioning sequence is divided into the following steps:

1. Perform circularity test

friction compensation

2. Perform circularity test

friction compensation and initial parameter values

3. Perform circularity tests with friction compensation and modified parameter values

4. Complete circularity tests with friction compensation and optimized parameter values

Circularity test without friction compensation

A circularity test without friction compensation should be performed to determine the initial quality of the circular contour at

the quadrant transitions. To do this, switch off the friction compensation temporarily:

MD32500 FRICT_COMP_ENABLE[ <axis> ] = 0

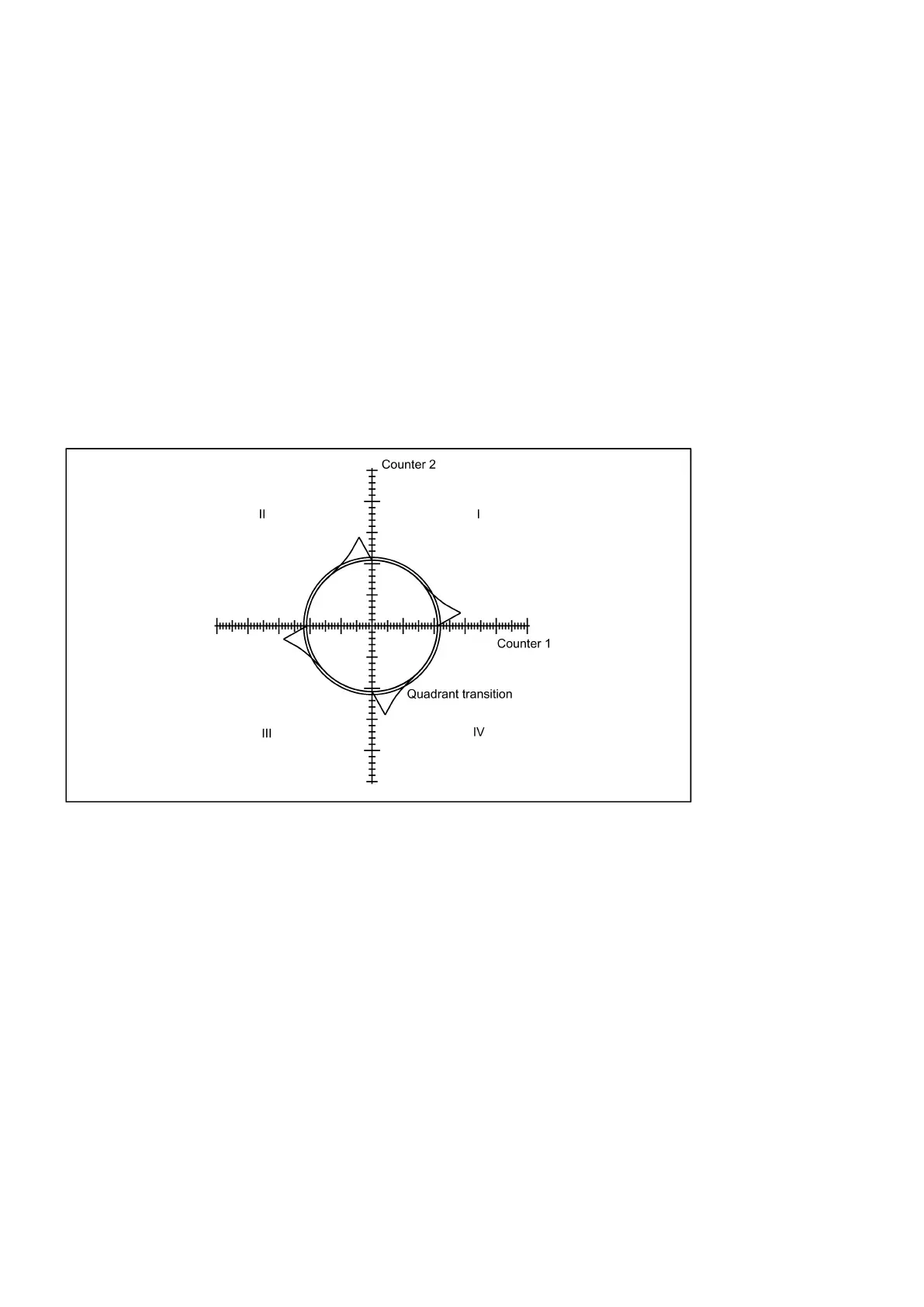

The following figure shows a typical example of quadrant transitions without friction compensation:

Then switch on the friction compensation with constant compensation value:

MD32500 FRICT_COMP_ENABLE[ <axis> ] = 1

Circularity test with friction compensation and initial parameter values

It is recommended that a relatively small compensation value, as well as a time constant of just a few position control cycles,

be set as initial parameter values, e.g.:

● MD32520 $MA_FRICT_COMP_CONST_MAX[ <axis> ] = 10 [mm/min]

● MD32540 $FRICT_COMP_TIME[ <axis> ] = 0.008 [ms]

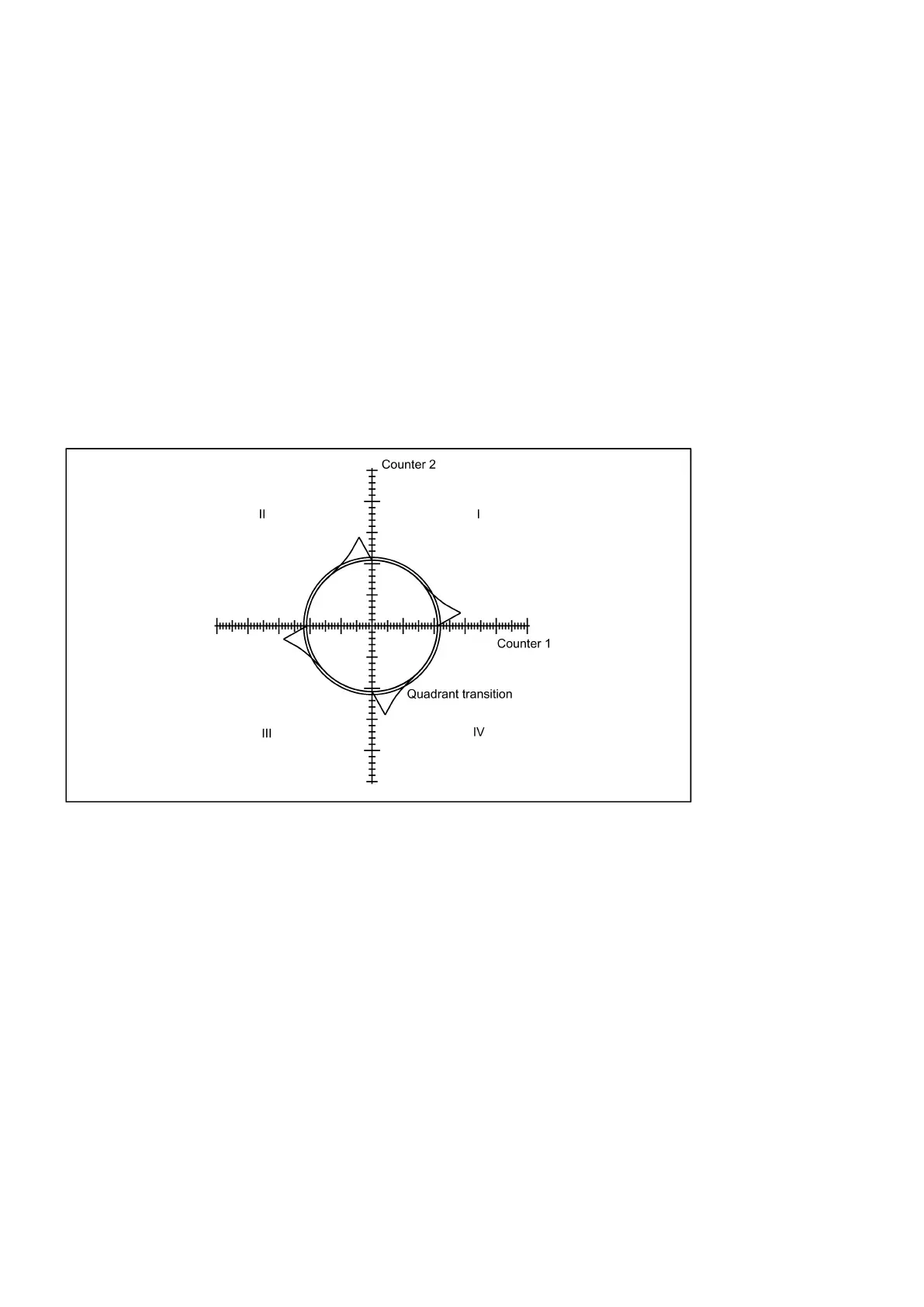

The circularity test performed with these parameter values provides an initial assessment of the friction compensation.

Loading...

Loading...