Function Manual

182 01/2017

Note

For representation in tables, it is assumed that geometry axes 1 to 3 are named X, Y, Z. The axis order (1st, 2nd and 3rd

g

eometry axis) but not the axis identifier determines the assignment between an offset and an axis.

Length compensation for tool type (SD42950 TOOL_LENGTH_TYPE)

Value of the setting data equal to 0:

The behavior corresponds to the standard definition: The lengths 1 to 3 in geometry and wear are assigned to the actual

(milling cutter / drill or turning tool).

SINUMERIK 808D/SINUMERIK 808D ADVANCED Programming and Operating Manual

Value of the setting data not equal to 0:

The assignment of the tool lengths is always independent of the actual tool type.

Value 1: Length assignment always as for milling tools.

Value 2: Length assignment always as for turning tools.

● The influence of these two setting data only refers to tool lengths. The tool radius is not affected.

● If SD42940 TOOL_LENGTH_CONST is set not equal to 0 and the value in SD42950 TOOL_LENGTH_TYPE is 1 or 2,

the related table for the assigned tool type (milling or turning tool) applies in SD42940.

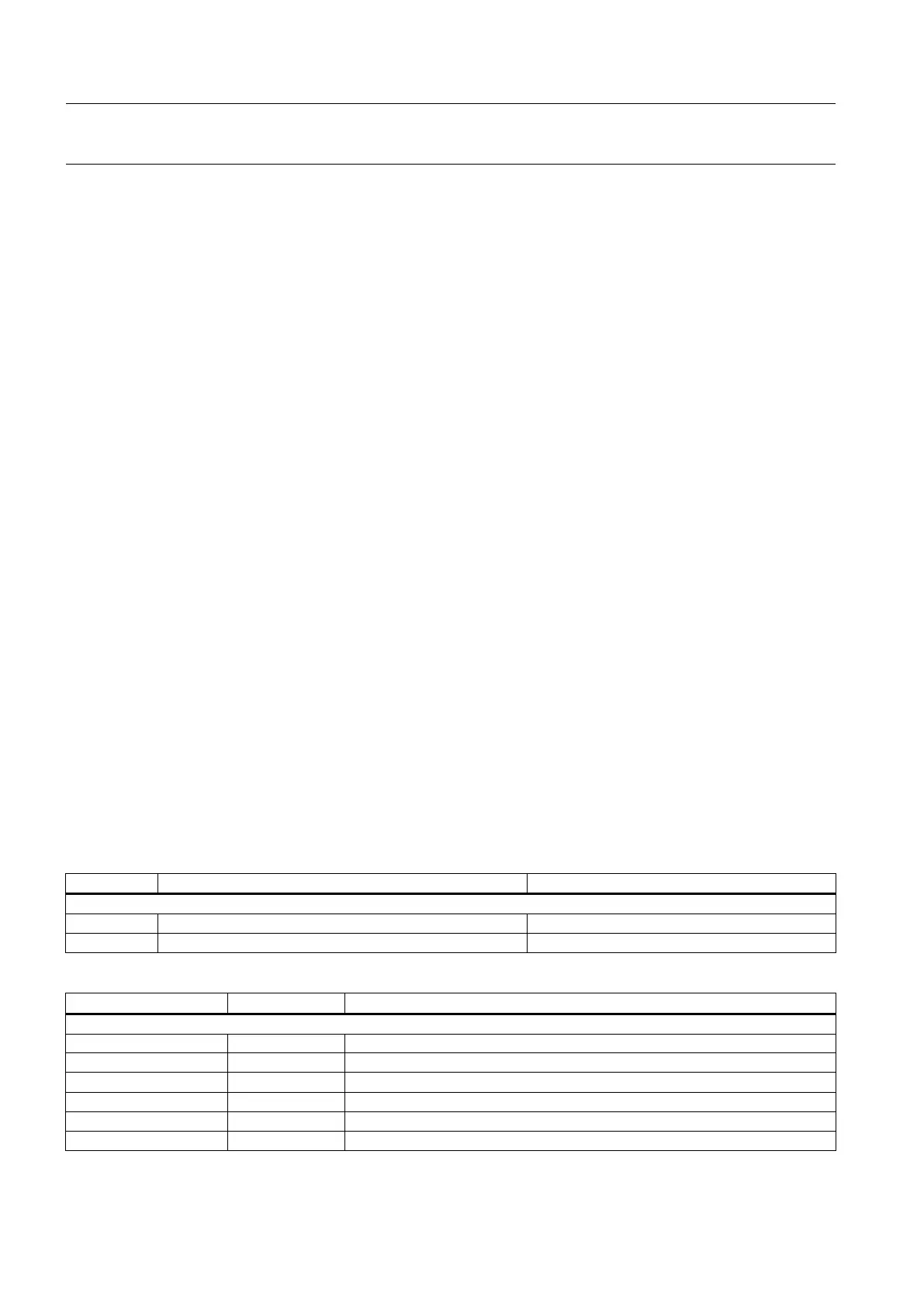

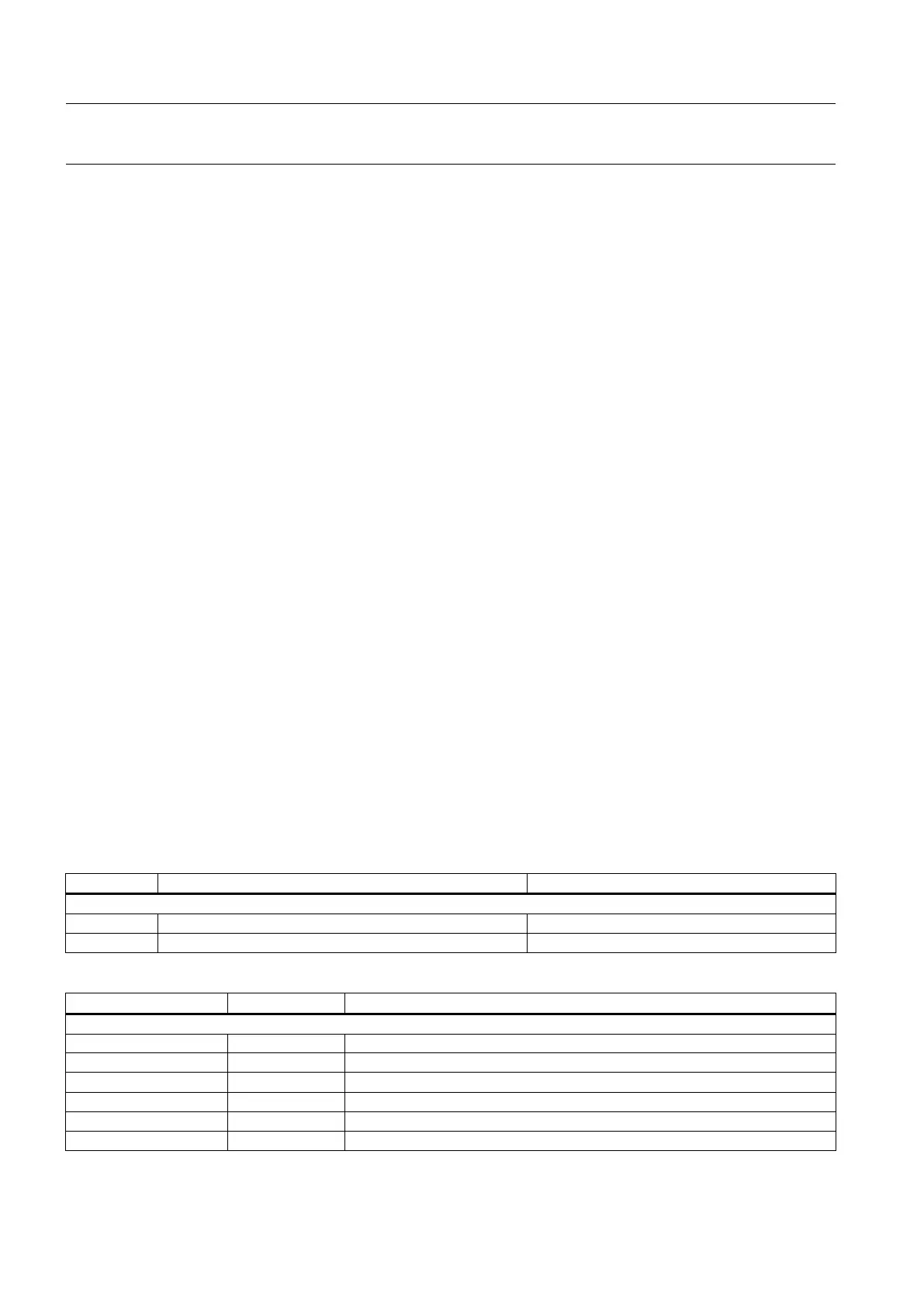

SD42940 TOOL_LENGTH_CONST =18

SD42950 TOOL_LENGTH_TYPE =2

Explanation:

The active tool with the active D number always behaves as a turning tool in the length compensation (-> SD42950 =2).

The length assignment is performed in all planes G17 to G19 as for G18 (-> SD42940=18):

Length 1 -> X axis

Length 2 -> Z axis

If Y axis exists: Length 3 -> Y axis

The tool radius acts according to the actual tool type and the active plane.

Definition of tool parameters

New tool offsets with M function

Deactivate workpiece counter

Loading...

Loading...