Function Manual

01/2017

21

The values to be written must be entered in the range DB120x.DBB1008...11 in the data type specific for the appropriate

variable.

If necessary, the values are converted (e.g. NCL floating-point values (64-bit) into the PLC format (32-bit) and vice versa). A

loss of accuracy results from the conversion from 64-bit to 32-bit REAL. The maximum accuracy of 32-bit REAL numbers is

approximately 10

7

.

Result, variable-specific part

A result is reported for each variable in the job.

If the read process was successful, "Variable valid" (DB120x.DBX3000.0) is set to 1; the access result DB120x.DBB3001 is

0.

When reading, the data as of DB120x.DBB3004 is entered type-specifically.

In case of error, DB120x.DBX3000.0 remains "0", and an entry is made in the access result DB120x.DBB3001:

● 0: No error

● 3: Illegal access to object

● 5: Invalid address

● 10: Object does not exist

The range DB120x.DBB3004...07 is not relevant for writing.

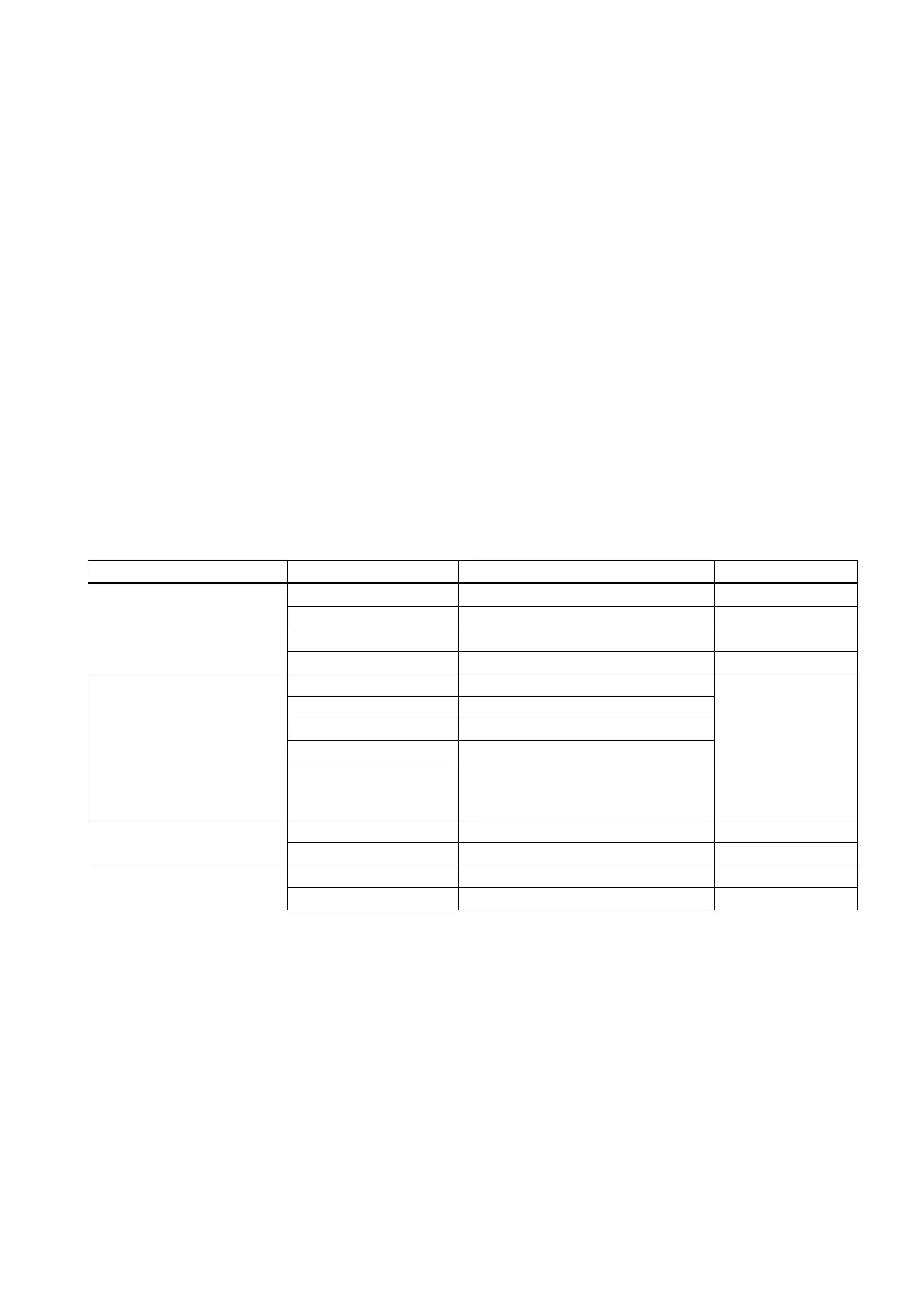

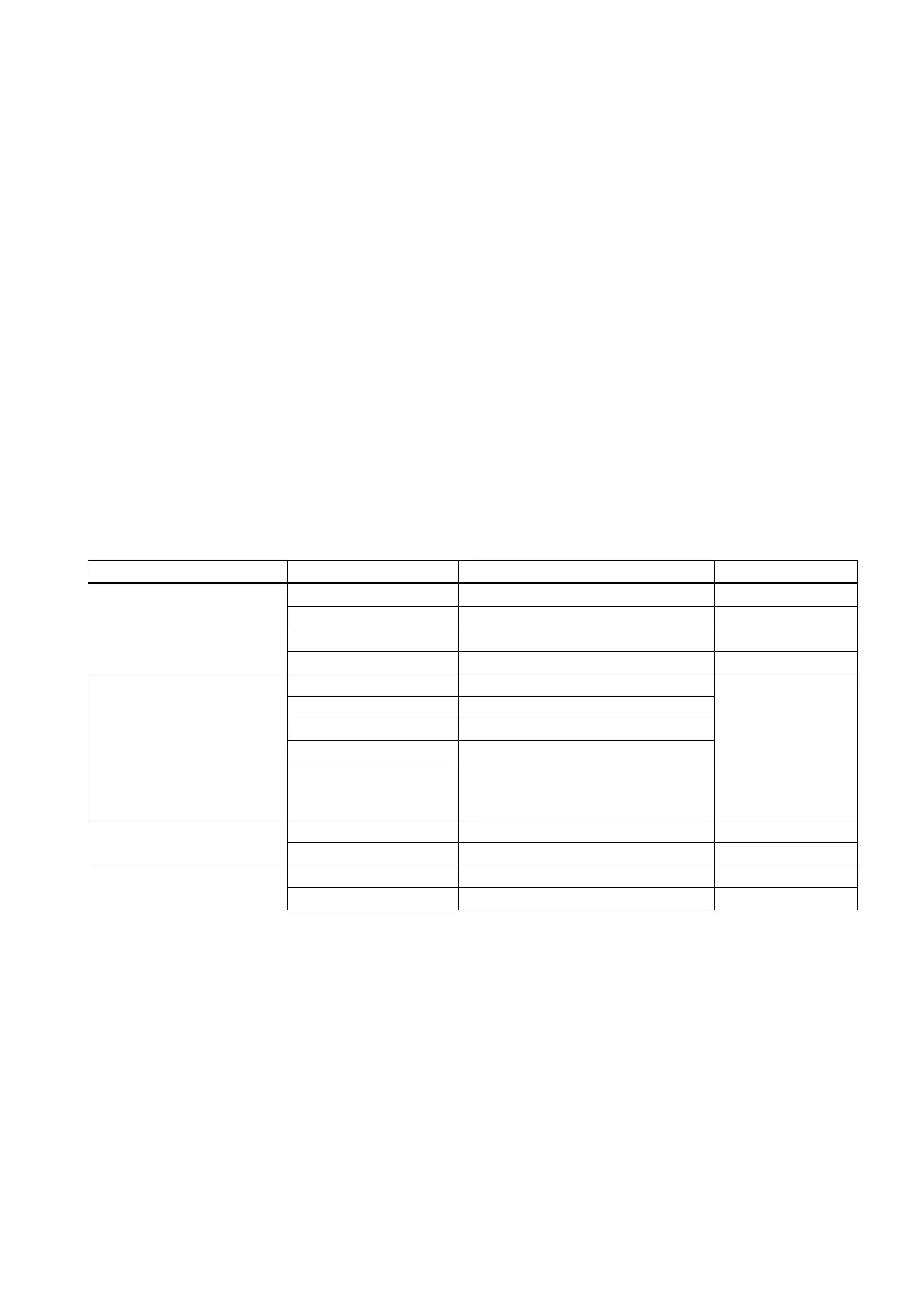

Relevant interface signals

Job, global part

Job, variable-specific part

See Section "NC

variable (Page 21)"

Column index, NCK variable

DB120x.DBB3004/

DB120x.DBW3004/

Value of NCK variable, data type de-

pends on variable index

Job, global part

Result, variable-specific part

NC variable

Variable cuttEdgeParam

Compensation value parameters and cutting edge list with D numbers for a tool.

The meanings of the individual parameters depend on the type of the tool in question. Currently, totally 25 parameters are

reserved for each tool edge (but only a part of them is loaded with values). To be able to remain flexible for future extensions,

it is not recommended to use a fixed value of 25 parameters for calculation, but the variable value 'numCuttEdgeParams'

(variable index 2).

For a detailed description of the tool parameters, please refer to Chapter "Tool Offset (Page 180)".

Loading...

Loading...