Function Manual

01/2017

149

ion of the power feed to the equipment is the responsibility of the machine manufacturer.

If the internal functions in the NC should not be executed in the predetermined sequence in the event of an

EMERGENCY STOP, then IS EMERGENCY STOP (DB2600.DBX0000.1) may not be set at any time up to the point that

an EMERGENCY STOP defined by the machine manufacture in the PLC user program is reached. As long as the

EMERGENCY STOP interface signal has not been set and no other alarm is active, all interface signals are

effective in

the NC. Any EMERGENCY STOP state defined by the manufacturer can therefore be assumed.

EMERGENCY STOP acknowledgment

Acknowledge EMERGENCY STOP

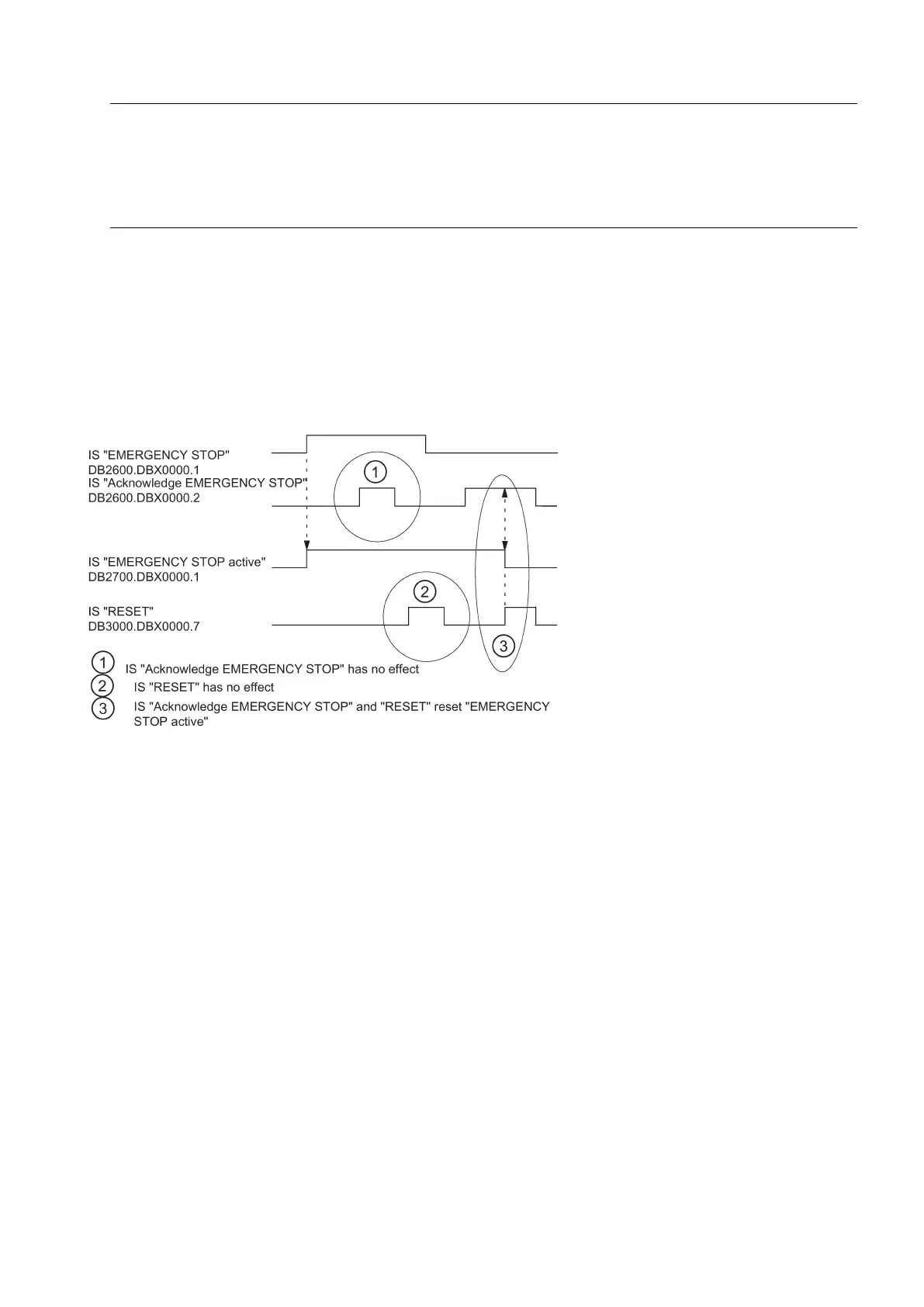

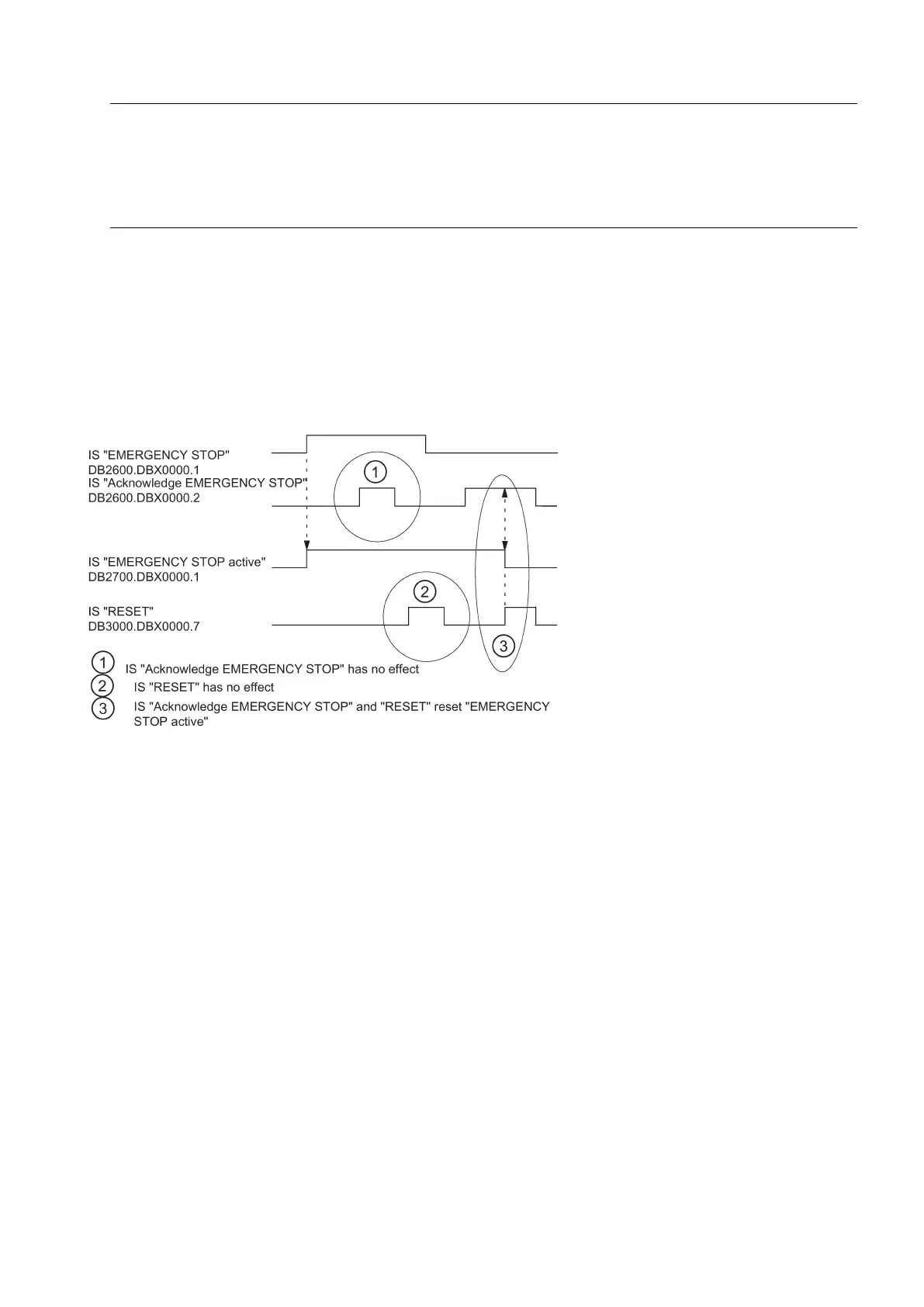

The EMERGENCY STOP state is reset only if IS "Acknowledge EMERGENCY STOP" (DB2600.DBX0000.2) followed by IS

"Reset" (DB3000.DBX0000.7) are set. It must be noted in this respect that IS "Acknowledge EMERGENCY STOP" and IS

"Reset" must be set (together) for a long enough period for IS "EMERGENCY STOP active" (DB2700.DBX0000.1) to be

reset.

Reset emergency stop:

Resetting the EMERGENCY STOP state has the following effects:

● IS "EMERGENCY STOP active" is reset.

● The controller enable is switched in.

● IS "Position control active" is set.

● IS "808D READY" is set.

● Alarm 3000 is cleared.

● The part program is aborted.

The PLC user program must switch the PLC I/O to the correct state for operation of the machine.

The EMERGENCY STOP state cannot be reset solely by IS "Reset" (DB3000.DBX0000.7) (see diagram above).

Power off/on (POWER ON) cancels the EMERGENCY OFF state unless IS "EMERGENCY OFF" (DB2600.DBX0000.1) is

still set.

Loading...

Loading...