Function Manual

176 01/2017

Rapid traverse G0

Application

The rapid traverse movement G0 is used for rapid positioning of the tool, but not for direct workpiece machining. All axes

can be traversed simultaneously. This results in a straight path.

For each axis, the maximum speed (rapid traverse) is defined in machine data MD32000 MAX_AX_VELO. If only one axis

traverses, it uses its rapid traverse. If, for example, two axes are traversed simultaneously, the path velocity (resulting

velocity) is selected to achieve the maximum possible path velocity under consideration of both axes.

If, for example, two axes have the same maximum velocity and also travel the same path, the path velocity = 1.41 * max.

axis velocity.

The feedrate F is not relevant for G0. It is, however, kept in the memory.

In "AUTO" operating mode, the feedrate override switch also applies to the rapid traverse through the following operations:

->

The active function is displayed with ROV in the status line. HMI to PLC sets the IS "Feedrate override for rapid traverse

selected" (DB1700.DBX0001.3). The PLC user program must place this signal on the IS "Rapid traverse override active"

(DB3200.DBX0006.6).

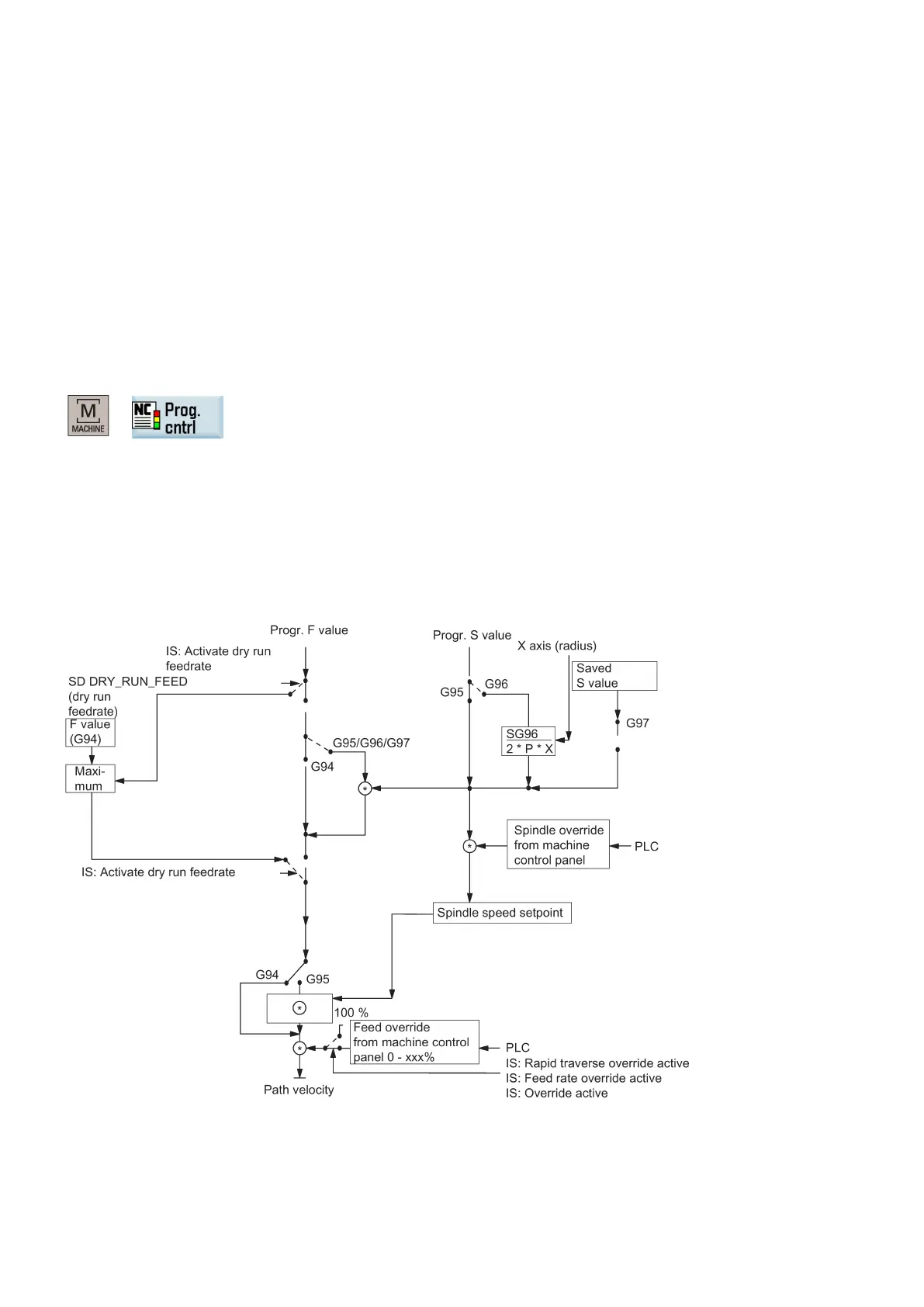

Possibilities for programming and controlling the feedrate:

Loading...

Loading...