Function Manual

134 01/2017

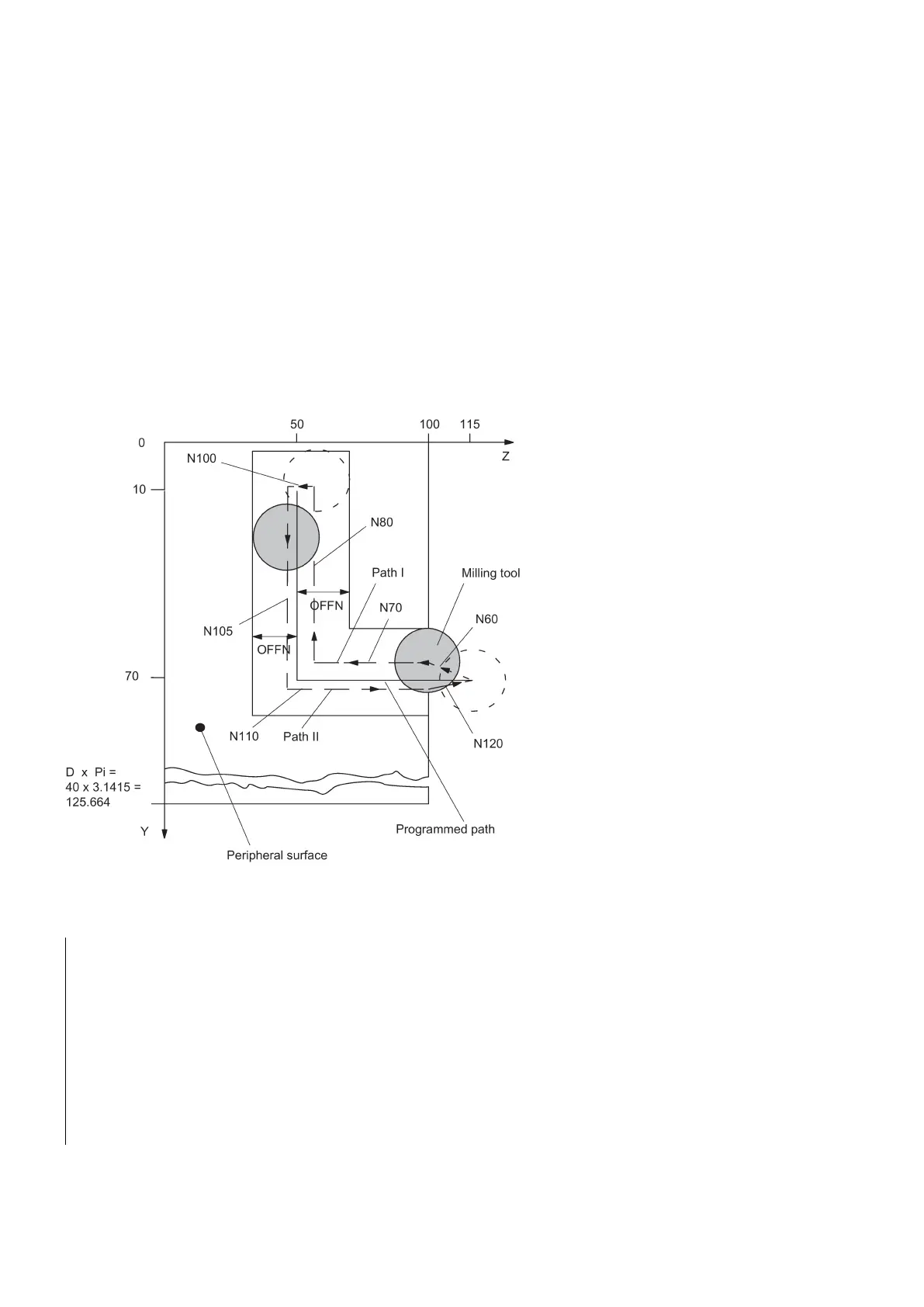

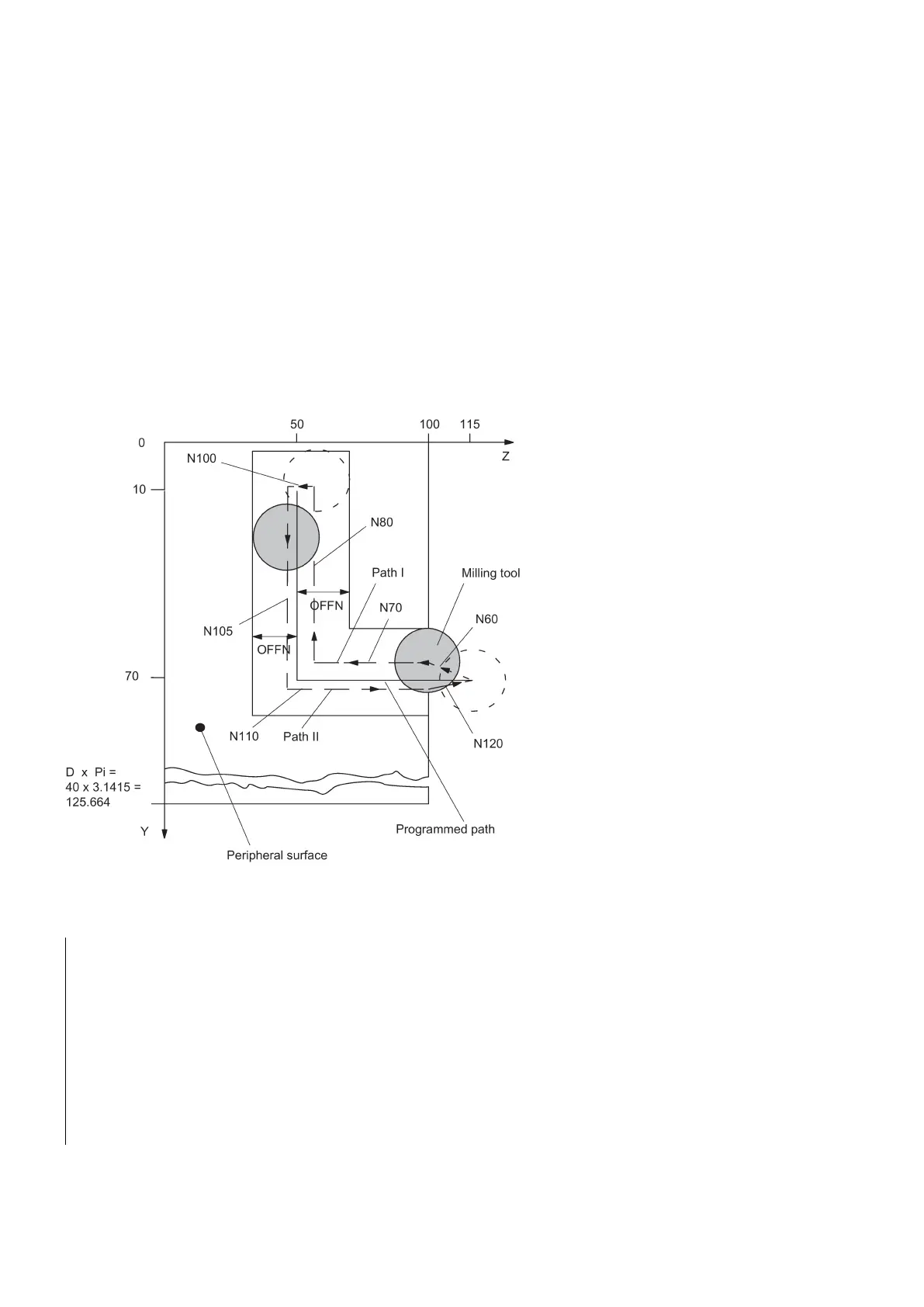

Programming example, TRACYL

Machining grooves with groove wall compensation

MD24100_TRAFO_TYPE_1 = 513

It is possible to machine a groove which is wider than the tool by using address

to program the compensation

direction (G41, G42) in relation to the programmed reference contour and the distance of the groove side wall from the

reference contour.

The tool radius in relation to the groove side wall is automatically taken into account with G41, G42. The full functionality of

the plane tool radius compensation is available (steady transition at outer and inner corners as well as solution of bottleneck

problems).

Groove with groove wall offset - figure as example:

TRACYL is used for the milling of grooves on a peripheral cylinder surface. During this process, the "Path I" and "Path II"

sections are processed using different OFFN values.

CC is the channel axis name of the rotary axis, milling radius of T1, D1: 8.000 mm

; set offset compensation and feedrate mode

; move to a safe position

; programming in radius mode

; transformation selection, reference diameter

; for surface: diameter 40 mm

; enable the second spindle as main spindle

; rotate the milling cutting tool

; machining plane is cylinder surface Y/Z

; X move to position with feedrate 200 mm/min

; tool radius compensation left of contour

Loading...

Loading...