Function Manual

01/2017

31

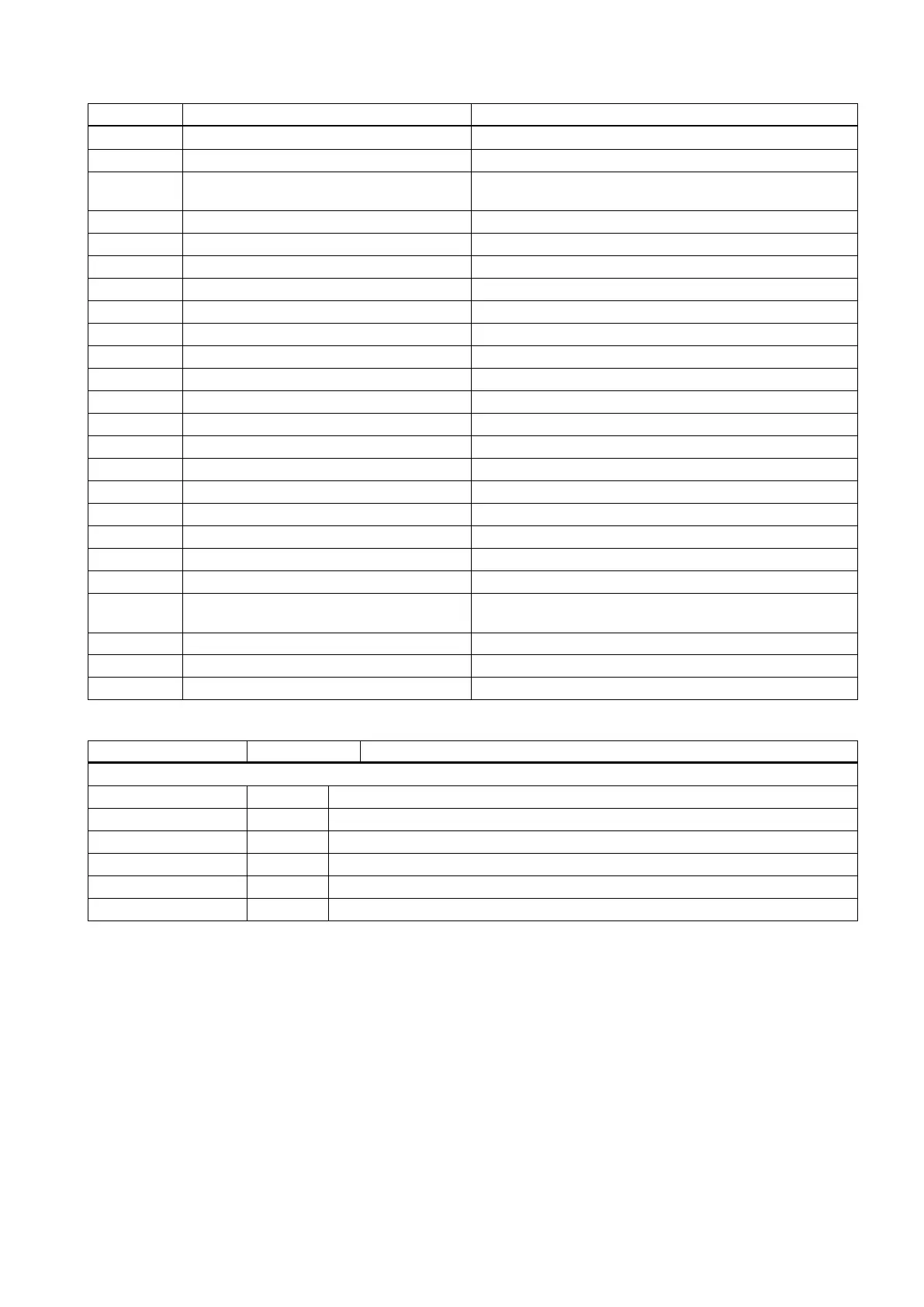

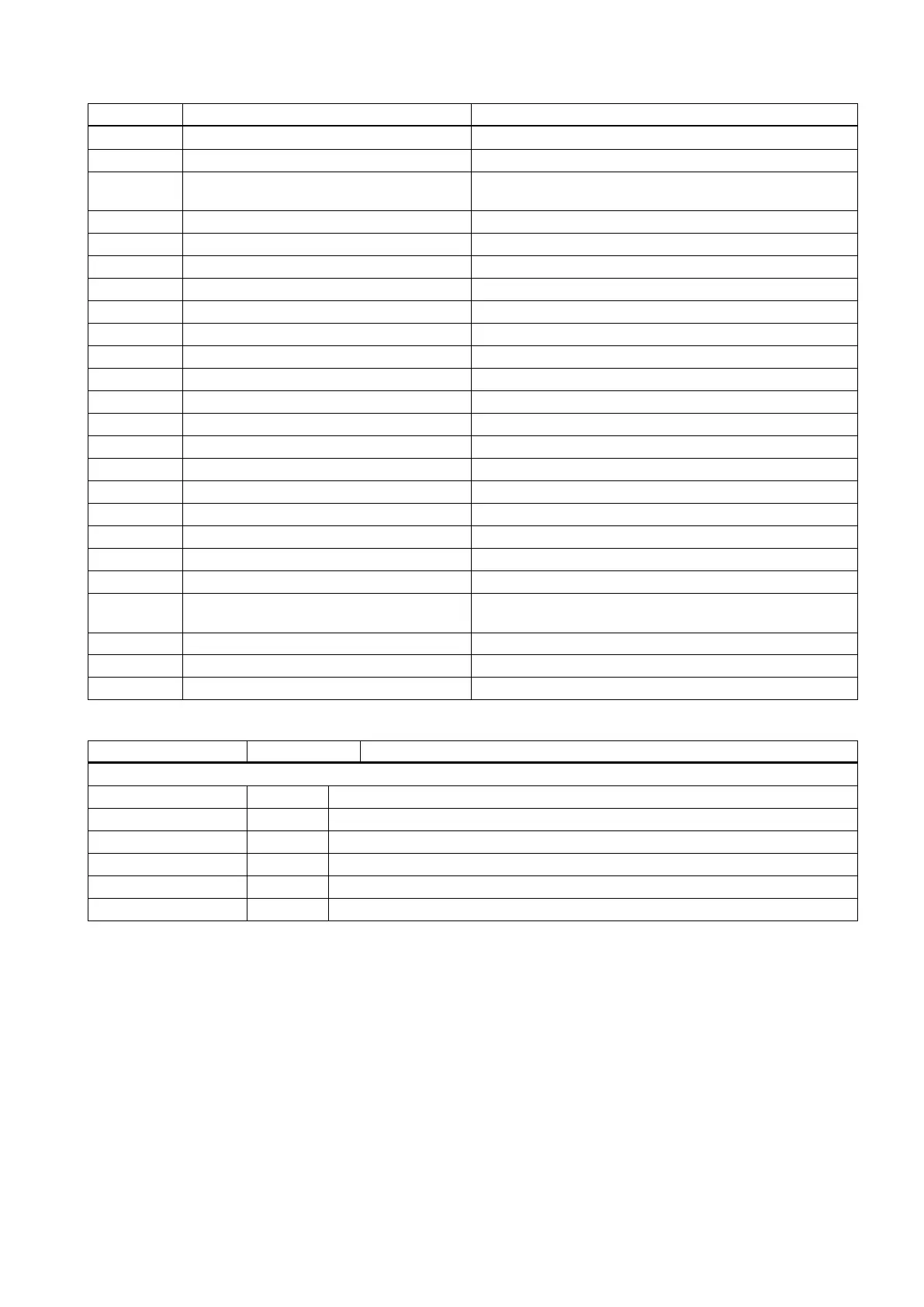

32810 EQUIV_SPEEDCTRL_TIME [n] Equivalent time constant speed control loop for feedforward

Time delay exact stop fine

Delay time standstill monitoring

Clamping tolerance with "Clamping active" interface signal

Maximum velocity/speed "Axis/spindle stationary"

1. Minus software limit switch

1. Plus software limit switch

2. Minus software limit switch

36130 POS_LIMIT_PLUS2 2. Plus software limit switch

Threshold value for velocity monitoring

Encoder limit frequency resynchronization

Tolerance band contour monitoring

36500 ENC_CHANGE_TOL High backlash values /

Maximum tolerance for actual position value changeover

Braking behavior at hardware limit switch

Length of the braking ramp for error states

Cutout delay controller enable

Axis/spindle-specific

Position measuring system 1

Hardware limit switch minus / hardware limit switch plus

2. Software limit switch minus / software limit switch plus

Encoder limit frequency exceeded 1

Referenced/synchronized 1

Continuous path mode, exact stop, and LookAhead (B1)

5.1

For continuous path control, the CNC processes a part program block by block. Only when the functions of the current block

have been completed, is the next block processed. Various requirements with respect to machining or positioning require

different block change criteria. There are two ways that the path axes can behave at block boundaries.

The first way is called "exact stop" and means that all path axes must have reached the set target position depending on an

exact-stop criterion before the next block change is initiated. To be able to fulfill the criterion, the path axes must reduce the

path velocity at every block change which, however, delays the block change.

Loading...

Loading...