Function Manual

174 01/2017

If the available path for run-in or run-out is limited, it may be necessary to reduce the spindle speed so that this path is

sufficient. In this case, the run-in and run-out paths can be specified separately in the program to achieve favorable cutting

values and short machining times or to simplify the handling of this issue.

If no values are specified, the values from the setting data (SD) apply. The specifications in the program are written in

SD42010 THREAD_RAMP_DISP[0] ... [1].

If this path is not sufficient for traversing at the configured axis acceleration, the axis is overloaded in terms of acceleration.

Alarm 22280 ("Programmed run-in path too short") is then issued for the thread run-in. The alarm is purely for information

and has no effect on part program execution.

The run-out path acts as an approximate distance at the end of the thread. This achieves a smooth change in the axis

movement when retracting.

DITS= ...: Run-in path of the thread

DITE= ...: Run-out path of the thread

SINUMERIK 808D/SINUMERIK 808D ADVANCED Programming and Operating Manual

Only paths, and not positions, are programmed with DITS and DITE.

With the part program instructions, the setting data SD42010 THREAD_RAMP_DISP[0], ...[1] defines the following

acceleration response of the axis during thread cutting ([0]-run-in, [1]-run-out):

● SD42010 = < 0 to -1:

Starting/braking of the feedrate axis at configured acceleration rate. Jerk according to current BRISK/SOFT programming.

● SD42010 = 0:

Abrupt starting/braking of the feedrate axis on thread cutting.

● SD42010 = > 0:

The thread run-up/deceleration distance is specified. To avoid technology alarm 22280, the acceleration limits of the axis

must be observed in case of very small run-in and run-out paths.

Note

DITE acts at the end of the thread a

s an approximate distance. This achieves a smooth change in the axis movement.

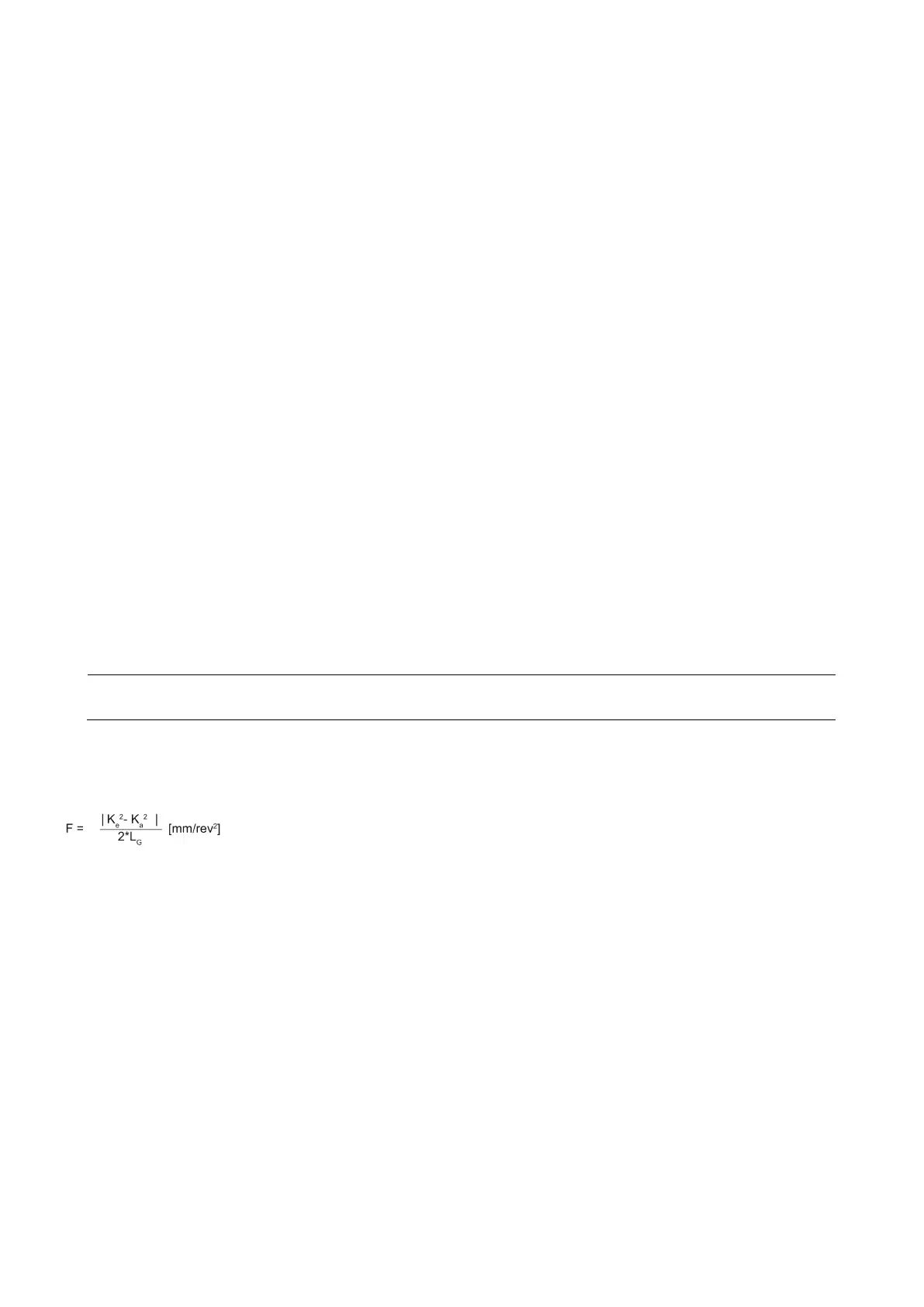

Pitch change F with G34, G35

If you already know the starting and final lead of a thread, you can calculate the pitch change F to be programmed according

to the following equation:

The identifiers have the following meanings:

Pitch of axis target point coordinate [mm/rev]

Initial pitch (progr. under I and K) [mm/rev]

Feedrate for G63 (tapping with compensation chuck)

Feedrate F

In the case of G63 it is necessary to program a feedrate F. It must be suitable for the selected spindle speed S (programmed

or set) and for the pitch of the drill:

Feedrate F [mm/min] = speed S [rev/min] x pitch [mm/rev]

The compensation chuck absorbs possible path differences of the drill axis to a limited extent.

SINUMERIK 808D/SINUMERIK 808D ADVANCED Programming and Operating Manual

Loading...

Loading...