W1: Tool offset

18.4 Tool cutting edge

Basic Functions

1450 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

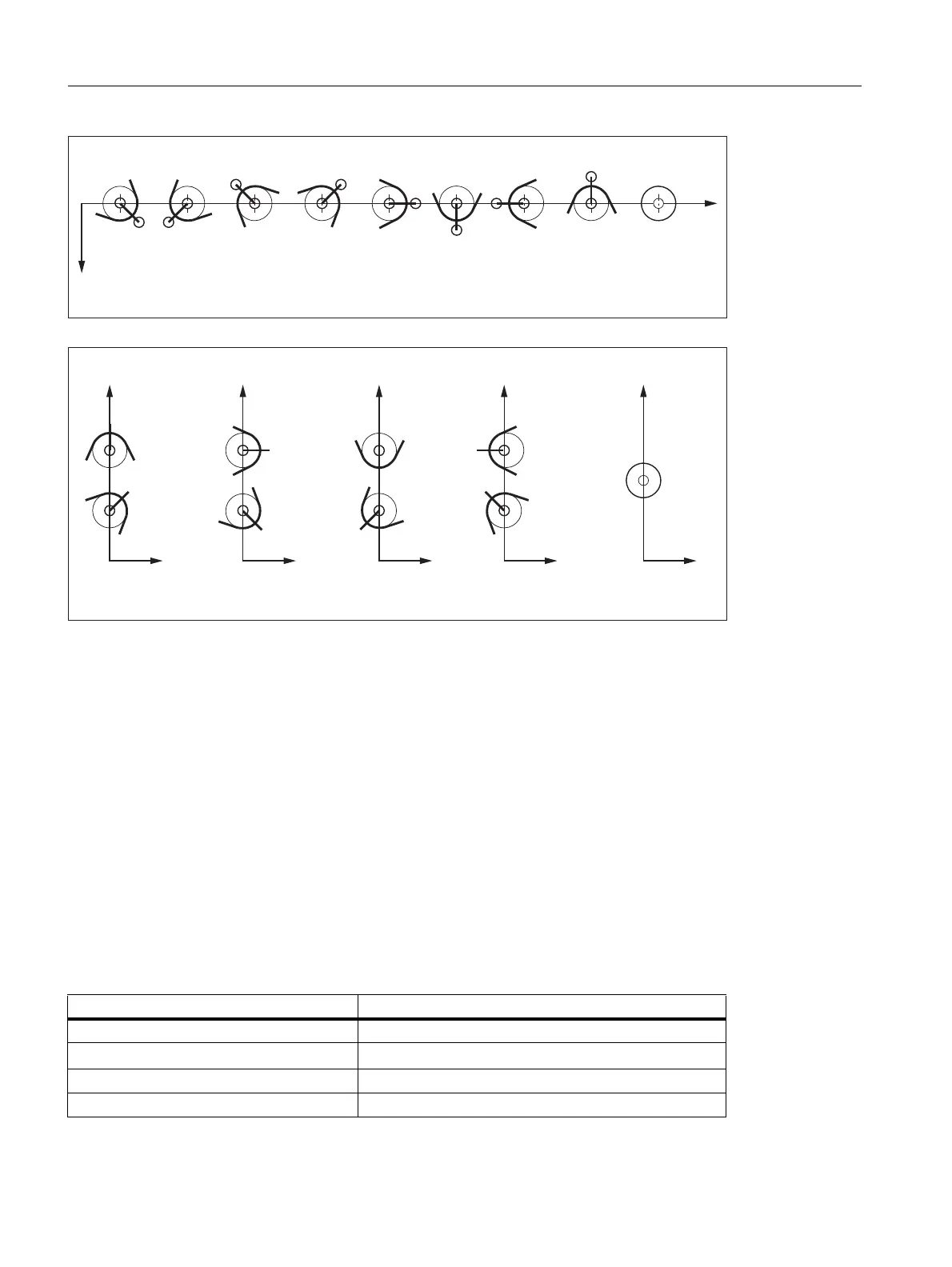

Figure 18-6 Tool parameter 2 (P2): Machining in front of the turning center

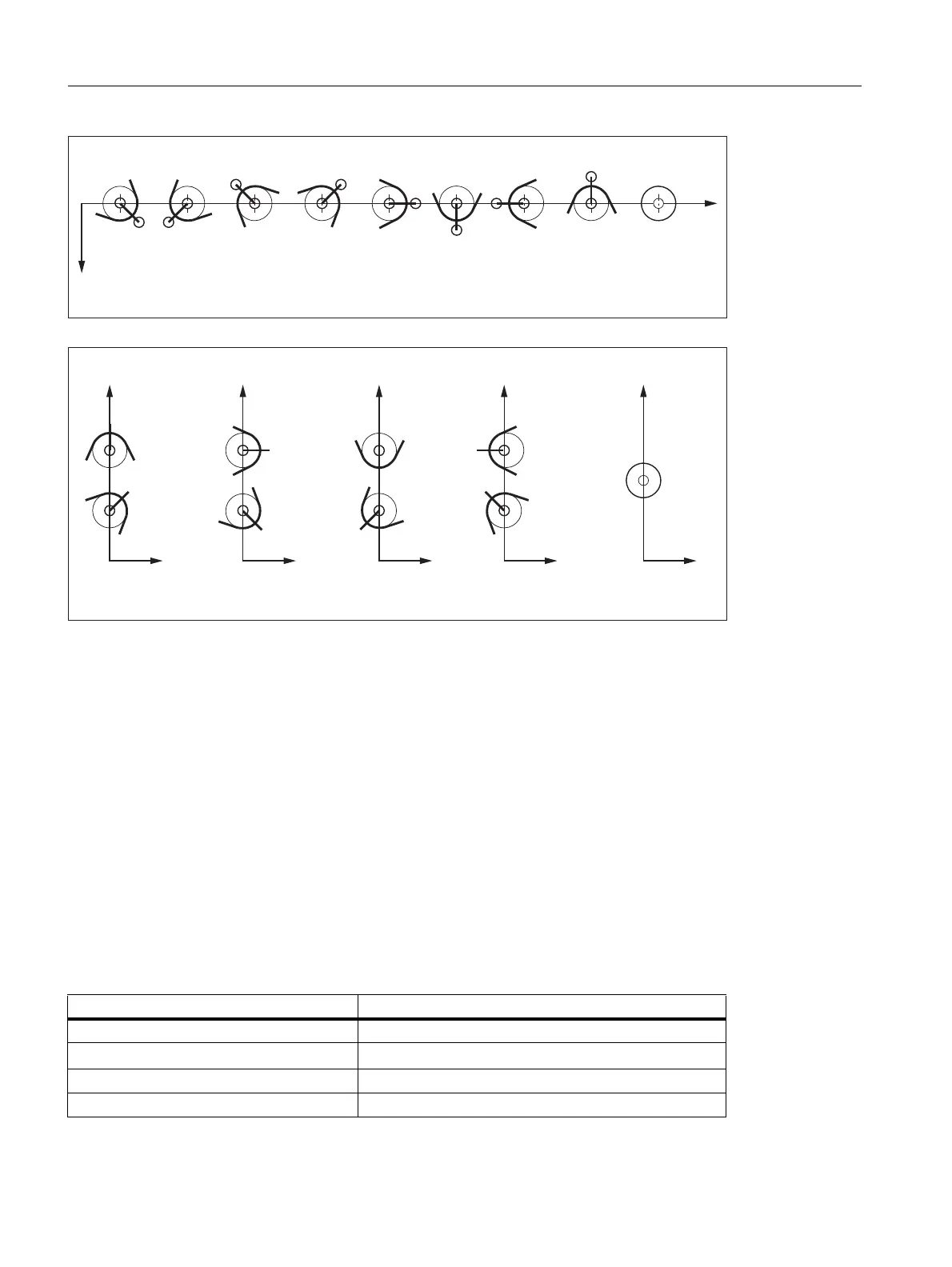

Figure 18-7 Tool parameter 2 (P2): Cutting edge position for vertical boring and turning mills

Special points to be noted

• If the cutting edge center point S is used instead of point P as a reference point to calculate the tool length

compensation, the identifier 9 must be entered for the cutting edge position.

• The identifier 0 (zero) is not permitted as a cutting edge position.

18.4.4 Tool parameters 3 - 5: Geometry - tool lengths

Description

The lengths of the tools are required for the geometry tool length compensation. They are input as tool lengths 1

to 3 in the tool parameters 3 to 5. The following length specifications must be entered as a minimum for each tool

type:

Tool type Required tool lengths

Tool type 12x, 140, 145, 150: Tool length 1

Tool type 13x: Tool length 1 to 3 (depending on plane G17-G19)

Tool type 2xx: Tool length 1

Tool type 5xx: Tool length 1 to 3

3 3 3 3 3 3 3

3 6

3 3

;

=

3

6

;

=

3 3

3

3 3

3 3

3 6

3

3

3

6

;

=

;

=

;

=

;

=

Loading...

Loading...