W1: Tool offset

18.4 Tool cutting edge

Basic Functions

Function Manual, 09/2011, 6FC5397-0BP40-2BA0

1455

• The tool and the tool adapter are measured separately but are installed on the machine in one unit (the tool

size and adapter size are entered separately in a cutting edge).

• The tool is used in a second tool fixture located in another position (e.g. vertical and horizontal spindle).

• The tool fixtures of a tool turret are located at different positions.

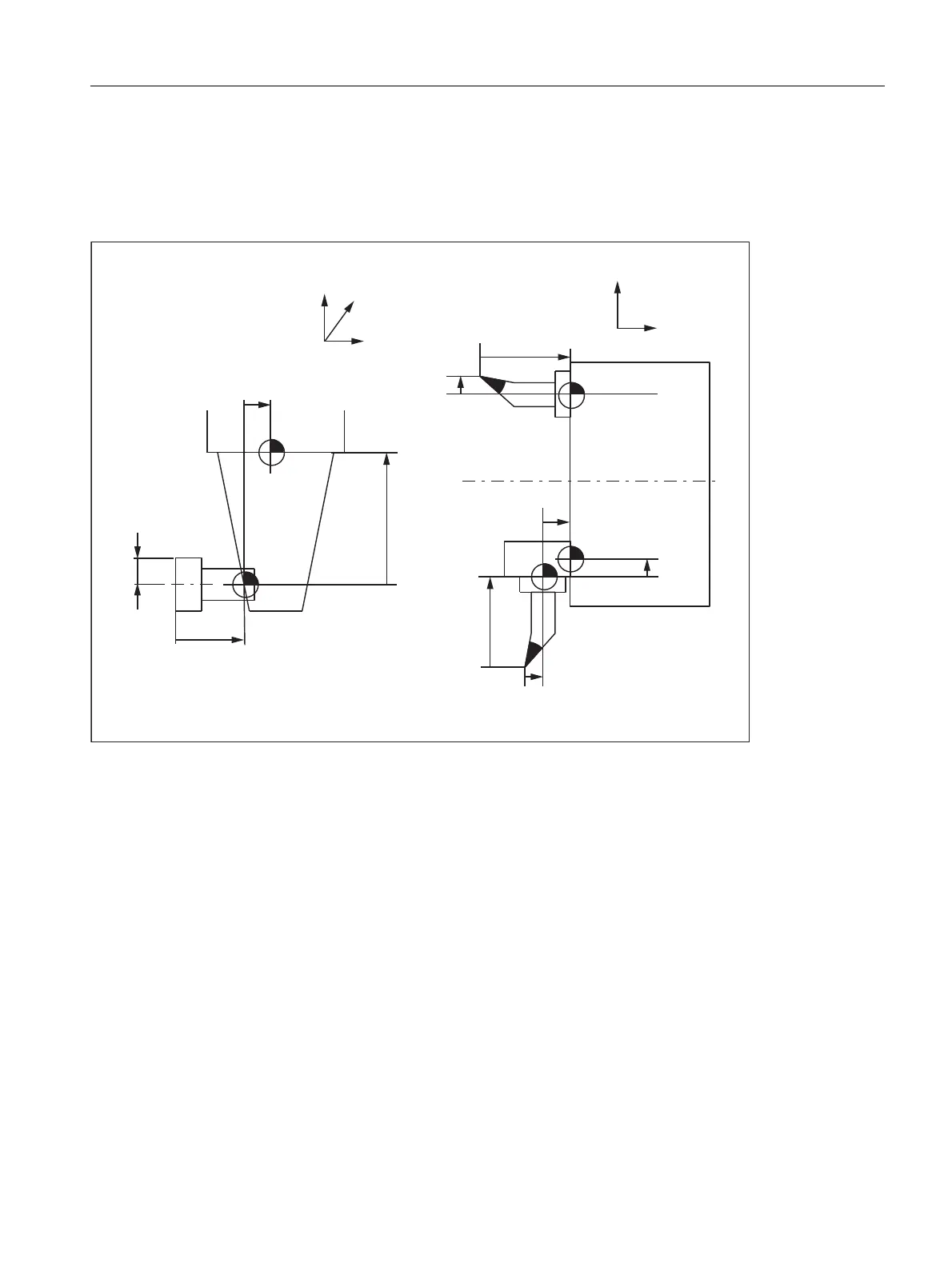

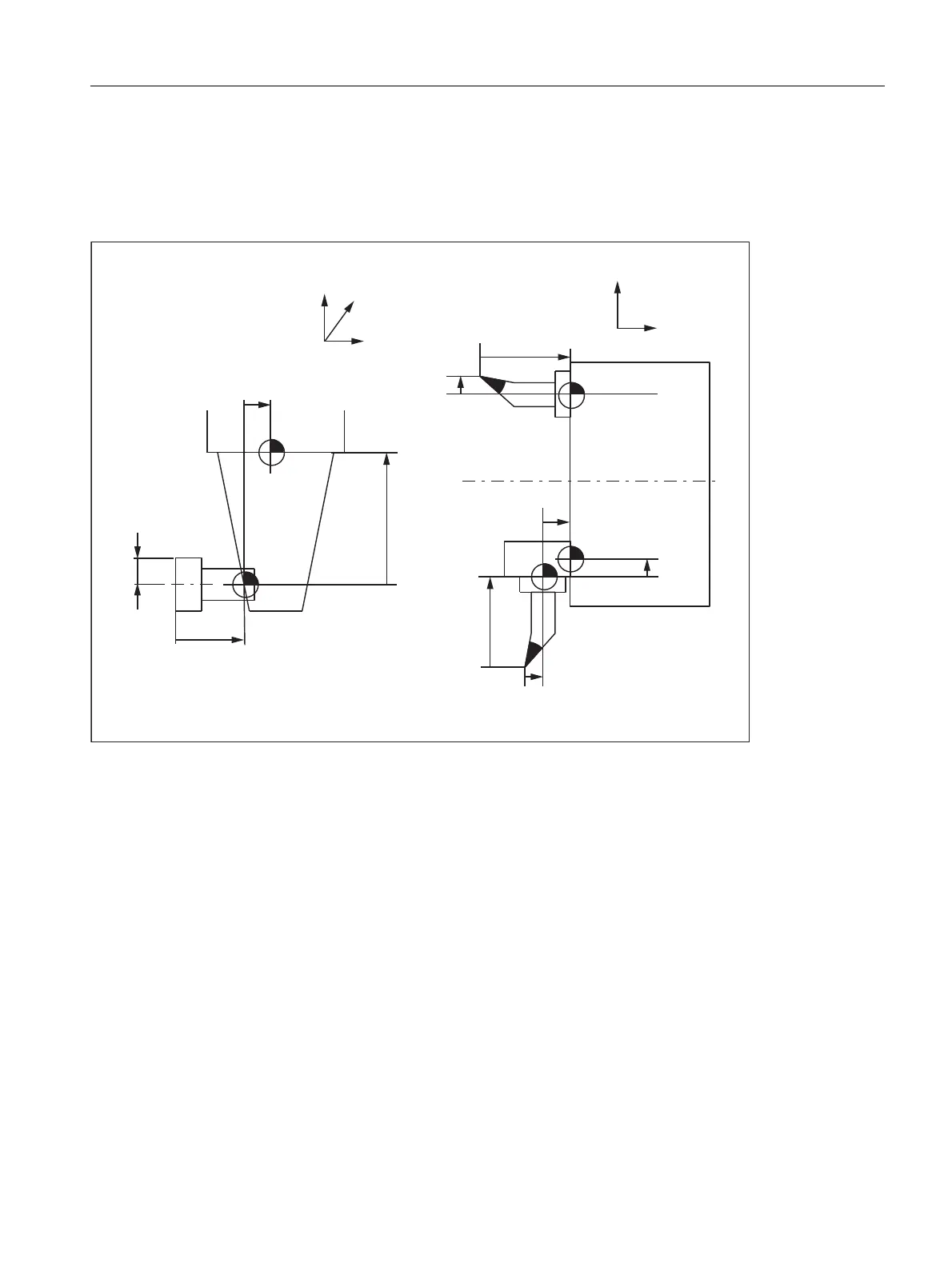

Figure 18-8 Application examples for base-dimension/adapter-dimension TLC

Tool basic length 1 to 3 (tool parameters 21 to 23)

In order that the discrepancy between the toolholder reference point F and the toolholder reference point F' can

be corrected on the three geometry axes (three dimensional), all 3 basic lengths are active irrespective of the tool

type. In other words, a twist drill (tool type 200) with a tool length compensation (length 1) can also have a tool

base dimension/adapter dimension in 3 axes.

References

Please refer to the following documentation for more information about base-dimension/adapter-dimension tool

length compensation:

• Programming Manual, Fundamentals

/HQJWK

/HQJWK

7XUQLQJFHQWHU

/HQJWK

/HQJWK

)7RROKROGHUUHIHUHQFHSRLQWV

)7RROKROGHUUHIHUHQFHSRLQWV

7RROEDVH

GLPHQVLRQ

OHQJWK

7RROEDVH

GLPHQVLRQ

OHQJWK

/HQJWK

5DGLXV

0LOOLQJPDFKLQH 7XUQLQJPDFKLQH

7RROEDVH

GLPHQVLRQ

OHQJWK

7RROEDVH

GLPHQVLRQ

OHQJWK

;

=

<

)

=

;

)

)

)

)

Loading...

Loading...