W1: Tool offset

18.5 Tool radius compensation 2D (TRC)

Basic Functions

Function Manual, 09/2011, 6FC5397-0BP40-2BA0

1471

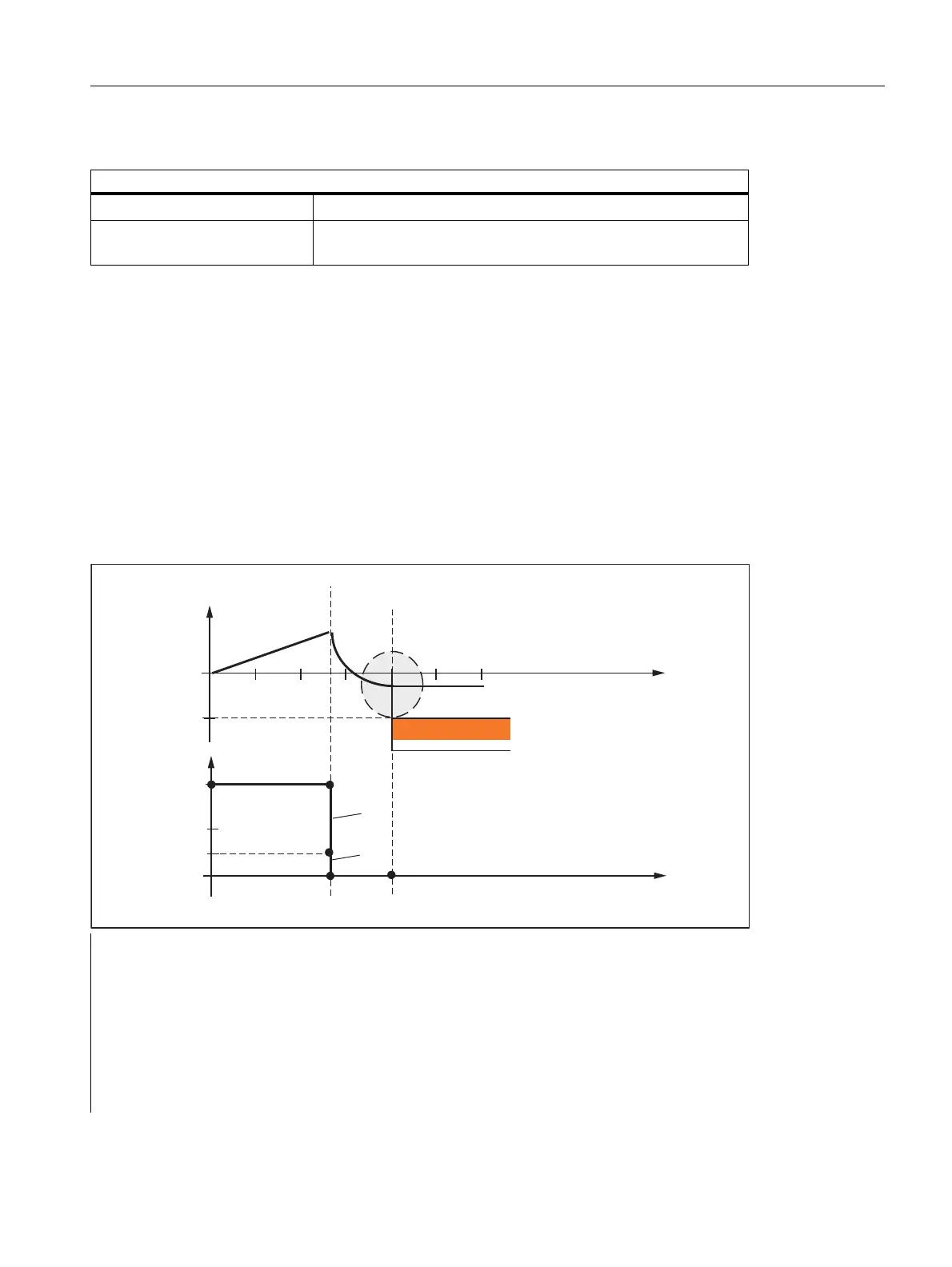

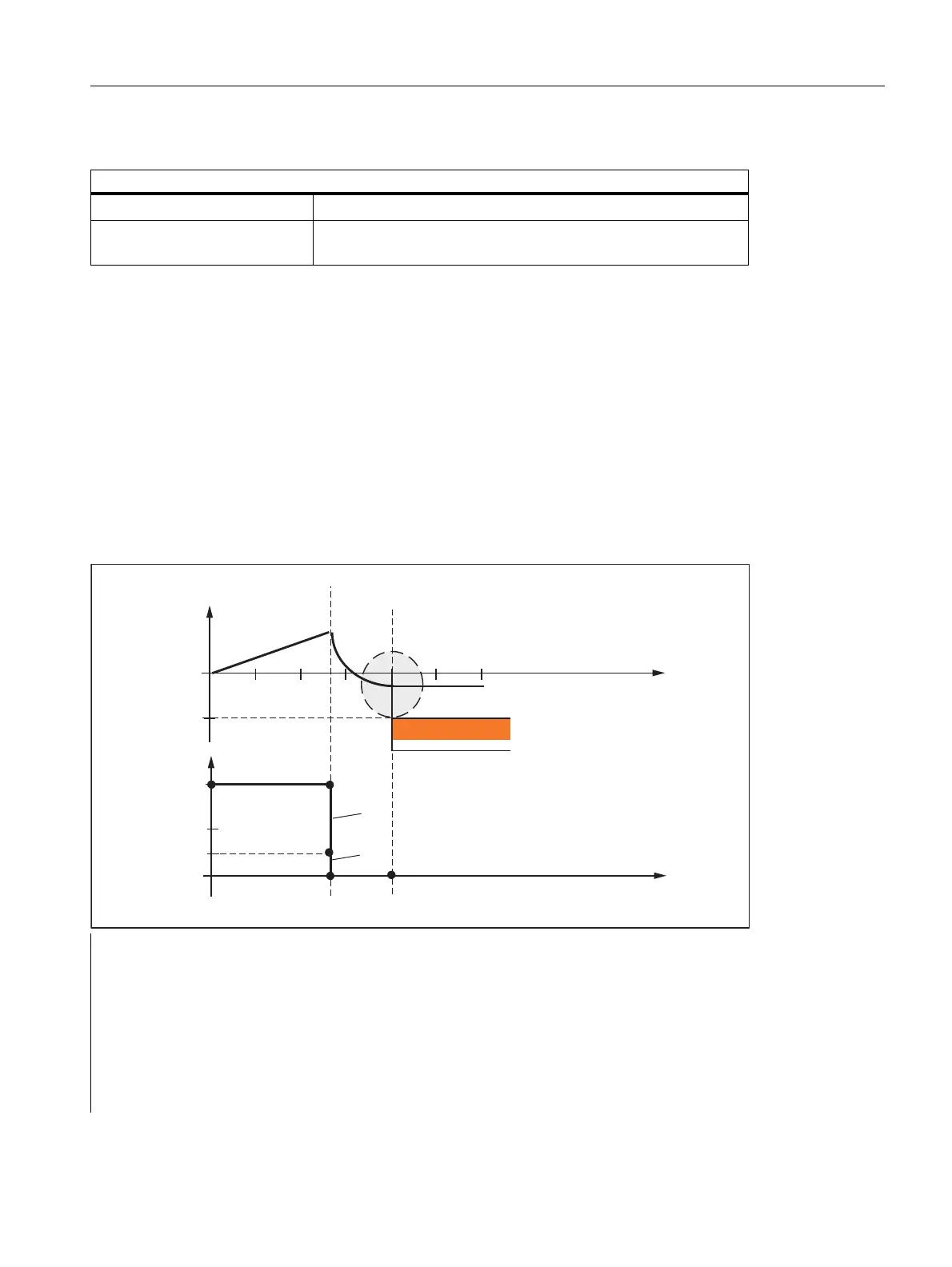

Programming the feedrate with FAD

If FAD is not programmed, this part of the contour is traversed at the velocity, which is active modally from the

preceding block, in the event that no F command defining the velocity is programmed in the SAR block.

Programmed response:

Example:

FAD programmed with ...

G340

Feedrate from P

2

or P

3

to P

4

.

G341

Feedrate of the infeed movement perpendicular to the machining

plane from P

2

to P

3

.

FAD=0 or negative → Alarm Output

FAD=...

→ Programmed value acts in accordance with the active G code

of group 15 (feed type; G93, G94, etc.)

FAD=PM(...)

→ Programmed value is interpreted as linear feed (like G94),

irrespective of the active G code of group 15

FAD=PR(...)

→ Programmed value is interpreted as revolutional feed (like

G95), irrespective of the active G code of group 15

$TC_DP1[1,1]=120 ;Milling tool T1/D1

$TC_DP6[1,1]=7 ;Tool with 7mm radius

N10 G90 G0 X0 Y0 Z20 D1 T1

N20 G41 G341 G247 DISCL=AC(5) DISR=13FAD 500 X40 Y-10 Z=0 F2000

N30 X50

N40 X60

...

3

))

)

*

;

;

3

3

33

*

=

<

Loading...

Loading...