W1: Tool offset

18.6 Toolholder with orientation capability

Basic Functions

Function Manual, 09/2011, 6FC5397-0BP40-2BA0

1507

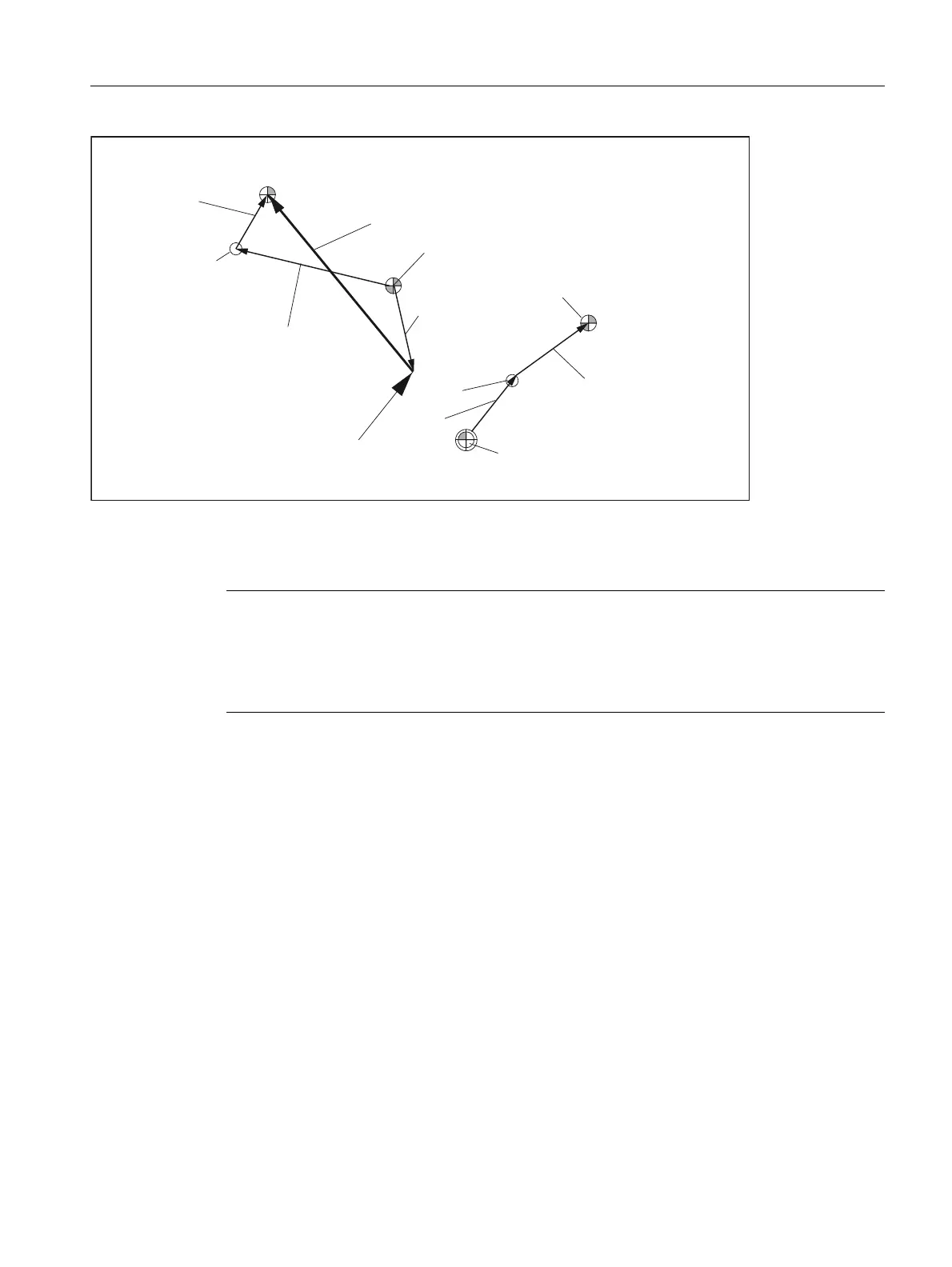

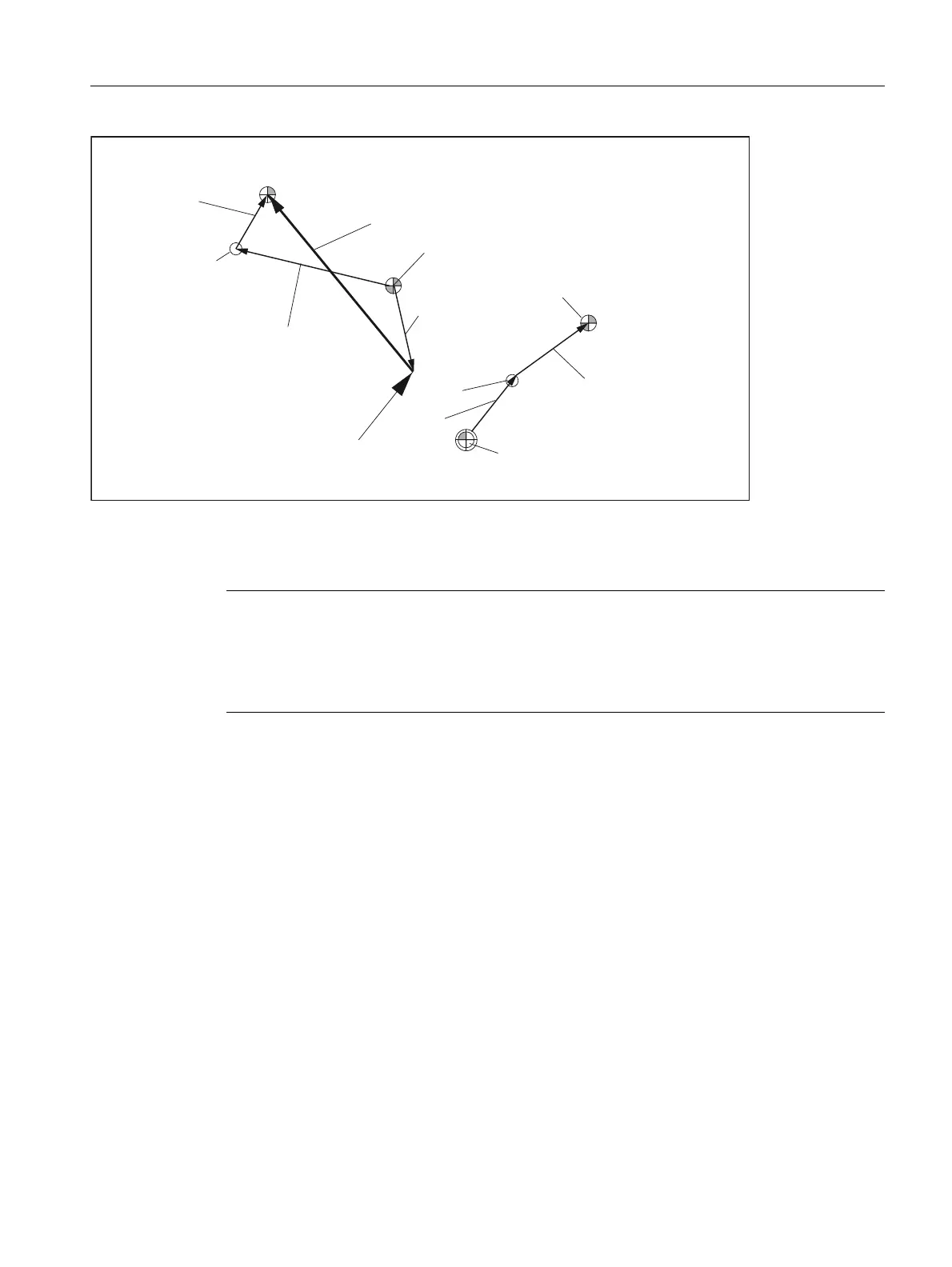

Figure 18-41 Kinematic sequence with extended kinematics

The following kinematic type is defined for machines with a rotary tool and rotary workpiece:

$TC_CARR23 using letter M (extended kinematics)

Rotary tool types T and M

For machine kinematics with a rotary tool (types T and M), the toolholder component with orientation capability,

which describes the tool or head component (as opposed to the table component), acts, in conjunction with the

active tool, as a new overall tool.

Fine offset

The offset vectors l

1

to l

4

and the offsets of the rotary axes v

1

and v

2

can be represented as the sum of a basic

value and a fine offset. The fine offset parameters assigned to the basic values are achieved by adding a value of

40 to the index of the basic value.

Note

On machines with extended kinematics it is generally useful, as with machines where only

the table can be rotated, for the machine reference point and the reference point of the table

to be identical. The (open) chain component to describe the table (see figure) is then closed.

In this special case, the following formula applies: l

3

= - l

4

7RROOHQJWK

ZHDU

WRROEDVHGLPHQVLRQ

5HVXOWLQJWRROOHQJWKFRPSHQVDWLRQ

5HIHUHQFHSRLQWRIWKHWRROKROGHU

7RRORULHQWDWLRQ

5HIHUHQFHSRLQWRIWKHWRRO

0DFKLQHUHIHUHQFHSRLQW

5HIHUHQFHSRLQWRIWKHWRROWDEOH

O

O

Y

˞

O

O

Y

˞

Loading...

Loading...