W1: Tool offset

18.6 Toolholder with orientation capability

Basic Functions

1514 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

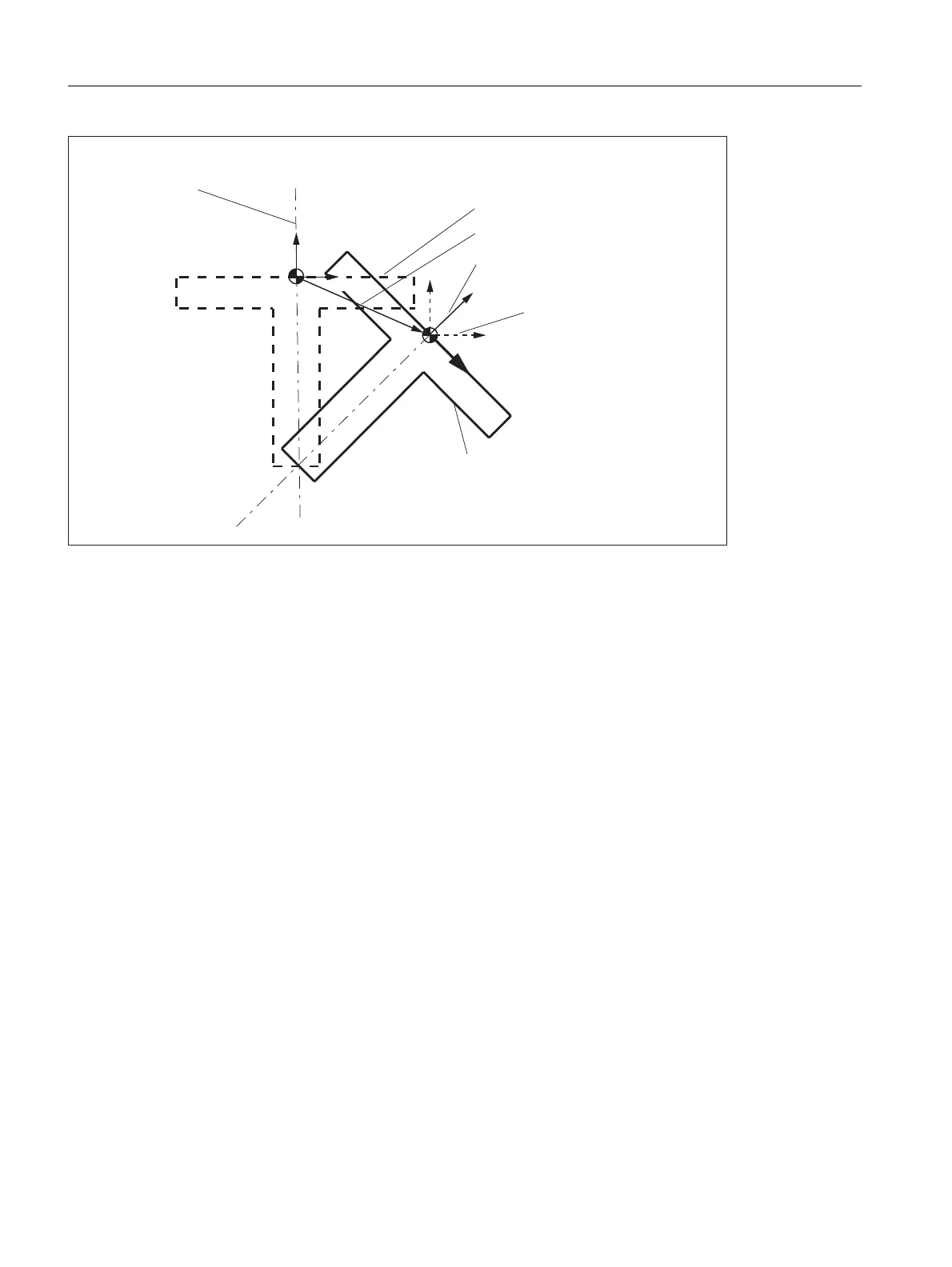

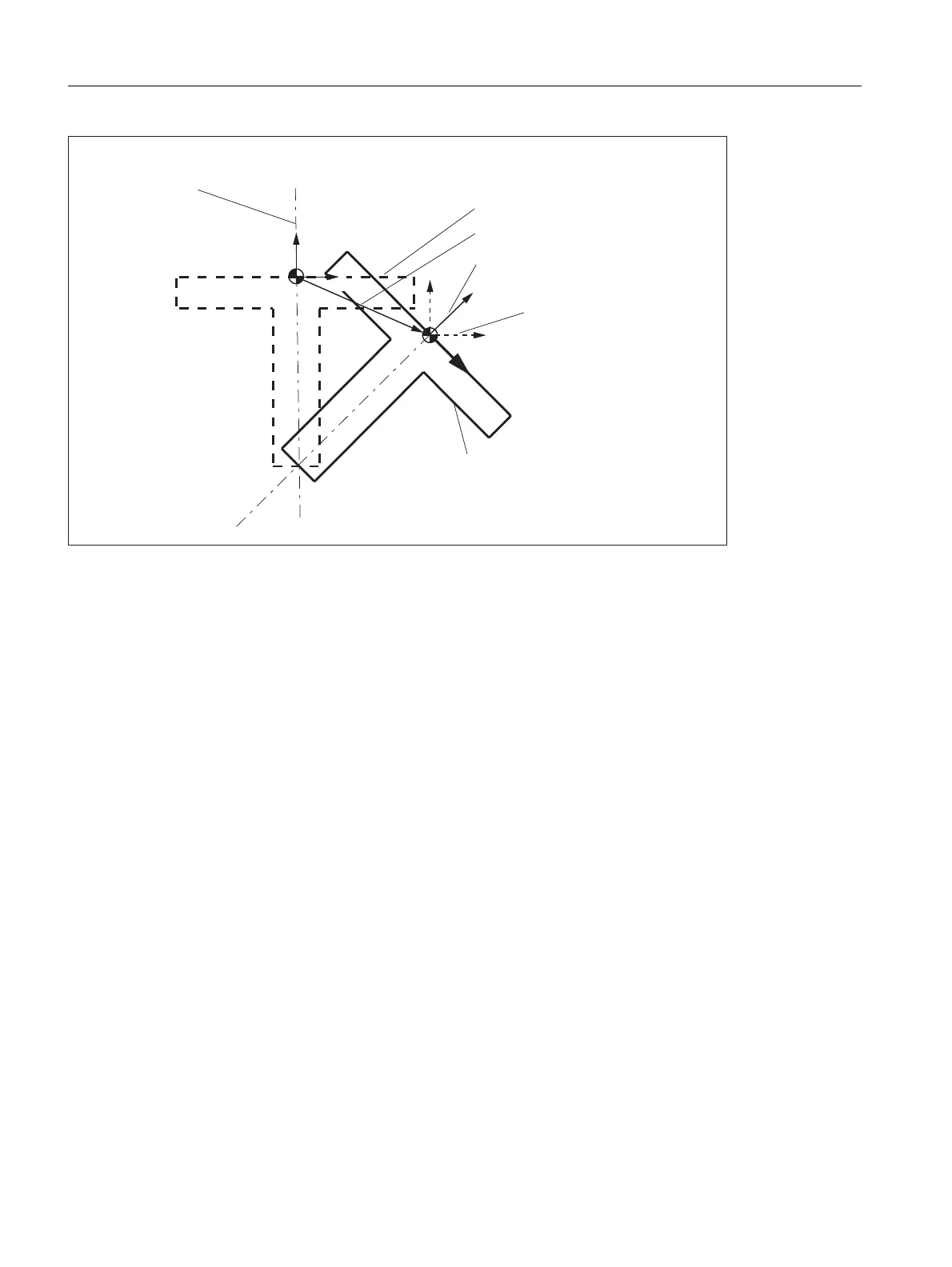

Figure 18-43 Zero offset on activation of a rotary table with TCARR

Example

On the machine in the figure, the rotary axis of the table is pointing in the positive Y direction. The table is rotated

by +45 degrees. PAROT defines a frame, which similarly describes a rotation of 45 degrees about the Y axis. The

coordinate system is not rotated relative to the actual environment (marked in the figure with "Position of the

coordinate system after TCARR"), but is rotated by -45 degrees relative to the defined coordinate system (position

after PAROT). If this coordinate system is defined with ROT Y-45, for example, and if the toolholder is then

selected with active TCOFR, an angle of +45 degrees will be determined for the rotary axis of the toolholder.

Rotary table

With rotary tables (kinematic types P and M), activation with TCARR similarly does not lead to an immediate

rotation of the coordinate system (see figure), i.e. even though the zero point of the coordinate system is offset

relative to the machine, while remaining fixed relative to the zero point of the workpiece, the orientation remains

unchanged in space.

Activation of kinematic types P and M

With kinematics of type P and M the selection of a toolholder activates an additive frame (table offset of the

toolholder with orientation capability), which takes into account the zero point offset as a result of the rotation of

the table.

The zero offset can be written to a dedicated system frame $P_PARTFR. For this, the bit 2 must be set in the

machine data:

MD28082 $MC_MM_SYSTEM_FRAME_MASK (System frames (SRAM))

The basic frame identified by following machine data is then no longer required for the zero offset:

2ULJLQDOSRVLWLRQRIWDEOH

3RVLWLRQRIWDEOHDIWHUURWDWLRQ

)UDPHRIIVHW

3RVLWLRQRIFRRUGLQDWHV\VWHP

DIWHU3$527

3RVLWLRQRIFRRUGLQDWHV\VWHP

DIWHU7&$55

2ULJLQDOSRVLWLRQRI

WKHFRRUGLQDWH

V\VWHP

=

;

=

;

=

;

Loading...

Loading...