G2: Velocities, setpoint / actual value systems, closed-loop control

7.4 Setpoint/actual-value system

Basic Functions

364 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

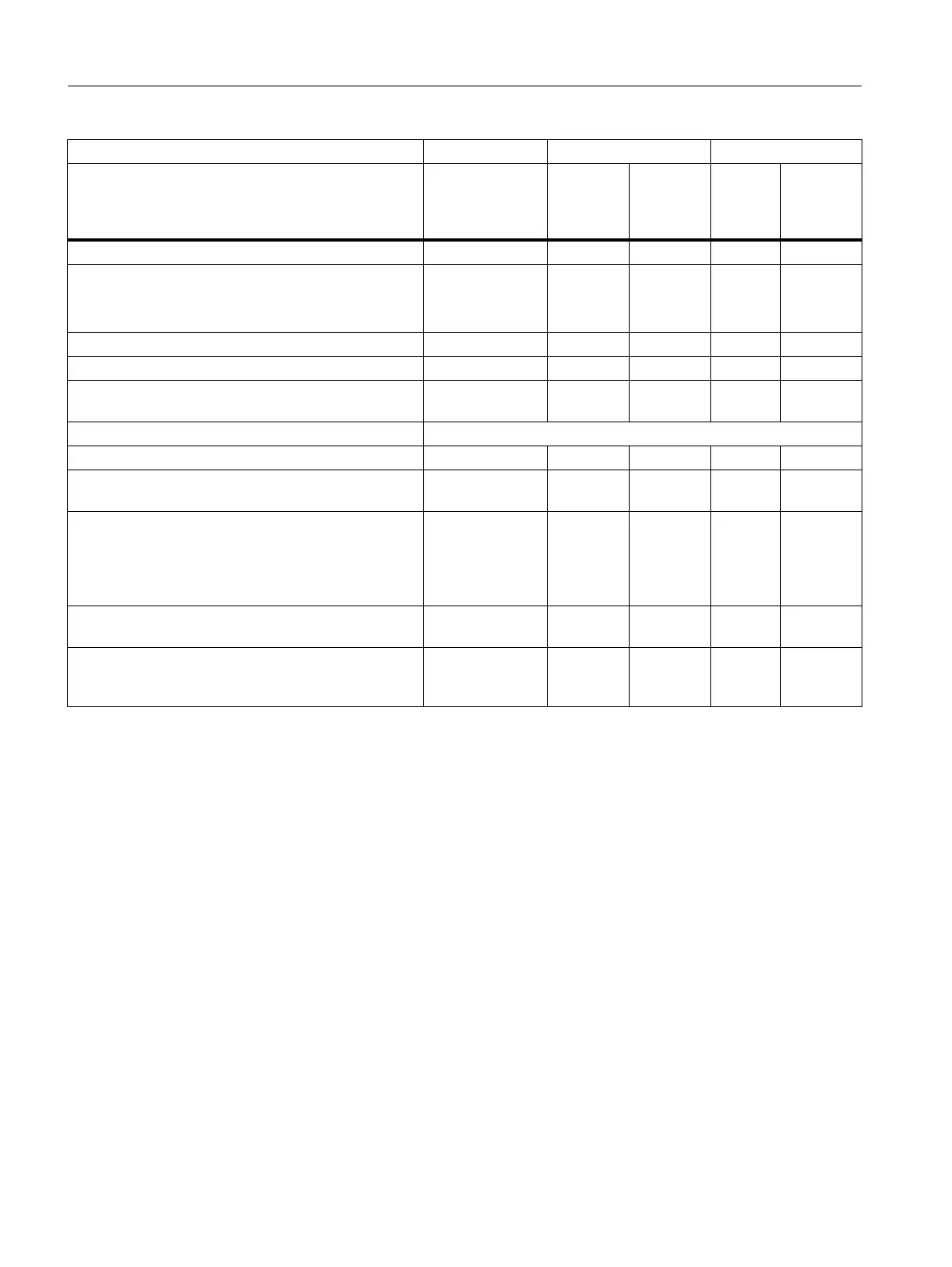

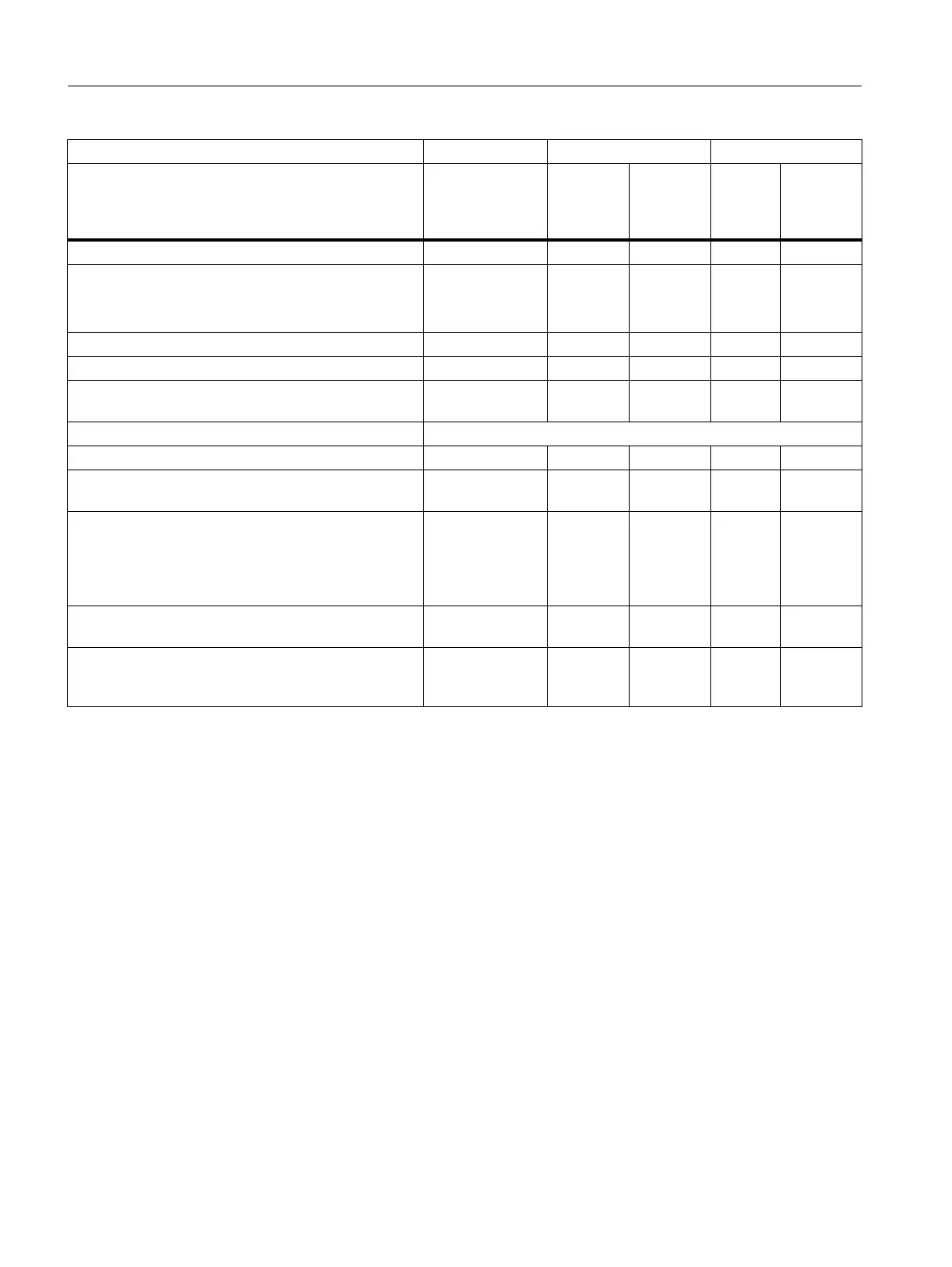

Machine data Linear axis Linear axis Rotary axis

Linear scale/

or as direct

measuring

system

Encoder

on

motor

Encoder

on

machine

and/or tool

Encoder

on

motor

Encoder

on

machine

and/or tool

MD30300 $MA_IS_ROT_AX 0 0 0 1 1

MD31000 $MA_ENC_IS_LINEAR[n]

MD31010 $MA_ENC_GRID_POINT_DIST[n]

MD34320 $MA_ENC_INVERS[n]

1

Spacing

◆

0

-

-

0

-

-

0

-

-

0

-

-

MD31040 $MA_ENC_IS_DIRECT[n] - / 1 0 1 0 1

MD31044 $MA_ENC_IS_DIRECT2[n] - / 1 0 1 0 1

MD31020 $MA_ENC_RESOL[n] - Pulses/

rev

Pulses/

rev

Pulses/

rev

Pulses/

rev

MD31025 $MA_ENC_PULSE_MULT[n] Encoder multiplication

MD31030 $MA_LEADSCREW_PITCH - mm/rev. mm/rev. - -

MD31050 $MA_DRIVE_AX_RATIO_DENOM[n] - Load

rev.

-/1 Load

rev.

●

MD31060 $MA_DRIVE_AX_RATIO_NUMERA[n] - Motor

rev. if

infeed

gear

available

-/1 Motor

rev.

●

MD31070 $MA_DRIVE_ENC_RATIO_DENOM[n] - Encoder

rev.

Encoder

rev.

Encoder

rev.

Encoder

rev.

MD31080 $MA_DRIVE_ENC_RATIO_NUMERA[n] - Motor-

side

encoder*

Motor

rev.

Motor

rev.

Load

rev.

- = Does not apply to this combination

* The encoder on the motor side is a built-in encoder and, therefore, does not have a

measuring gear unit.

The transmission ratio is always 1:1.

◆ For distance-coded measuring systems

● These machine data are not required for encoder matching (path evaluation).

However, they must be entered correctly for the setpoint calculation! Otherwise the

required servo gain factor (K

V

) will not be set. The load revolutions are entered into

machine data MD31050 $MA_DRIVE_AX_RATIO_DENOM and the motor revolutions

in machine data MD31060 $MA_DRIVE_AX_RATIO_NUMERA.

Loading...

Loading...