P3: Basic PLC Program for SINUMERIK 840D sl

13.13 Block descriptions

Basic Functions

962 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

• T number of the tool

The location where the tool is positioned traverses;

the "tool identifier", "duplo number", "location number_from" and

"magazine number_from" parameters are irrelevant (i.e. values "" , "-0001", "-0001","-0001").

or

• Tool identifier and duplo number

The location where the tool is positioned traverses;

the "T number", "location number_from" and "magazine number_from" parameters are irrelevant (i.e. value "-

0001" each).

or

• Direct specification of the location in the "location_number_from" and "magazine_number_from" parameters

The tool-qualifying parameters T number, "tool identifier" and "duplo number" are irrelevant (i.e. values "-

0001", "", "-0001").

PI service: TMPCIT

Function: Set increment value for workpiece counter

Incrementing the workpiece counter of the spindle tool

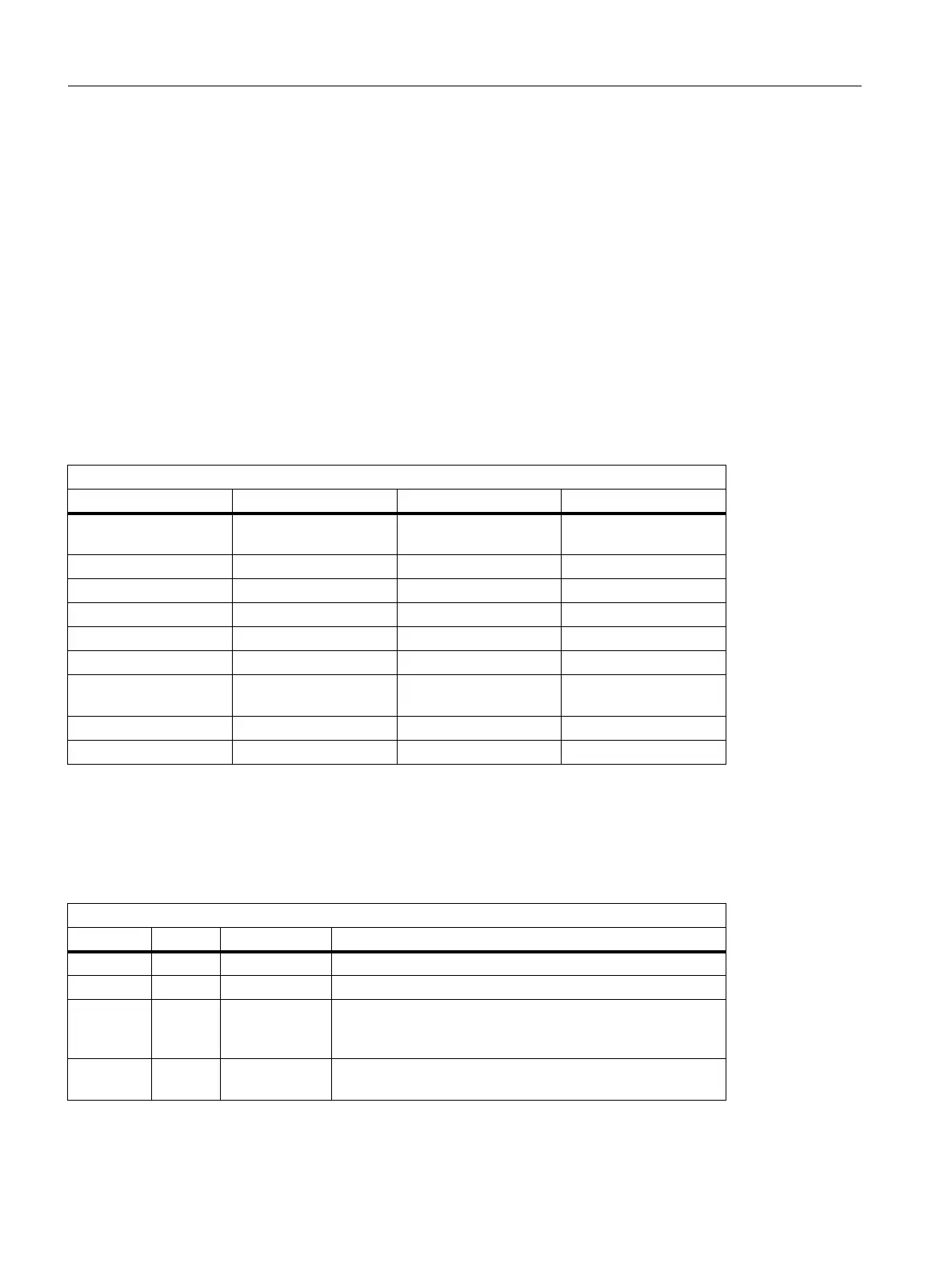

Parameterization

Signal Type Value range Meaning

PIService ANY PI.TMPOSM Position magazine

location or tool

Unit INT 1 ... 10 TOA

Addr1 STRING max. 32 characters Tool identifier

WVar1 INT T number

WVar2 INT Duplo number

WVar3 INT Location_number_from

WVar4 INT Magazine_number_fro

m

WVar5 INT Location number_ref

WVar6 INT Magazine number_ref

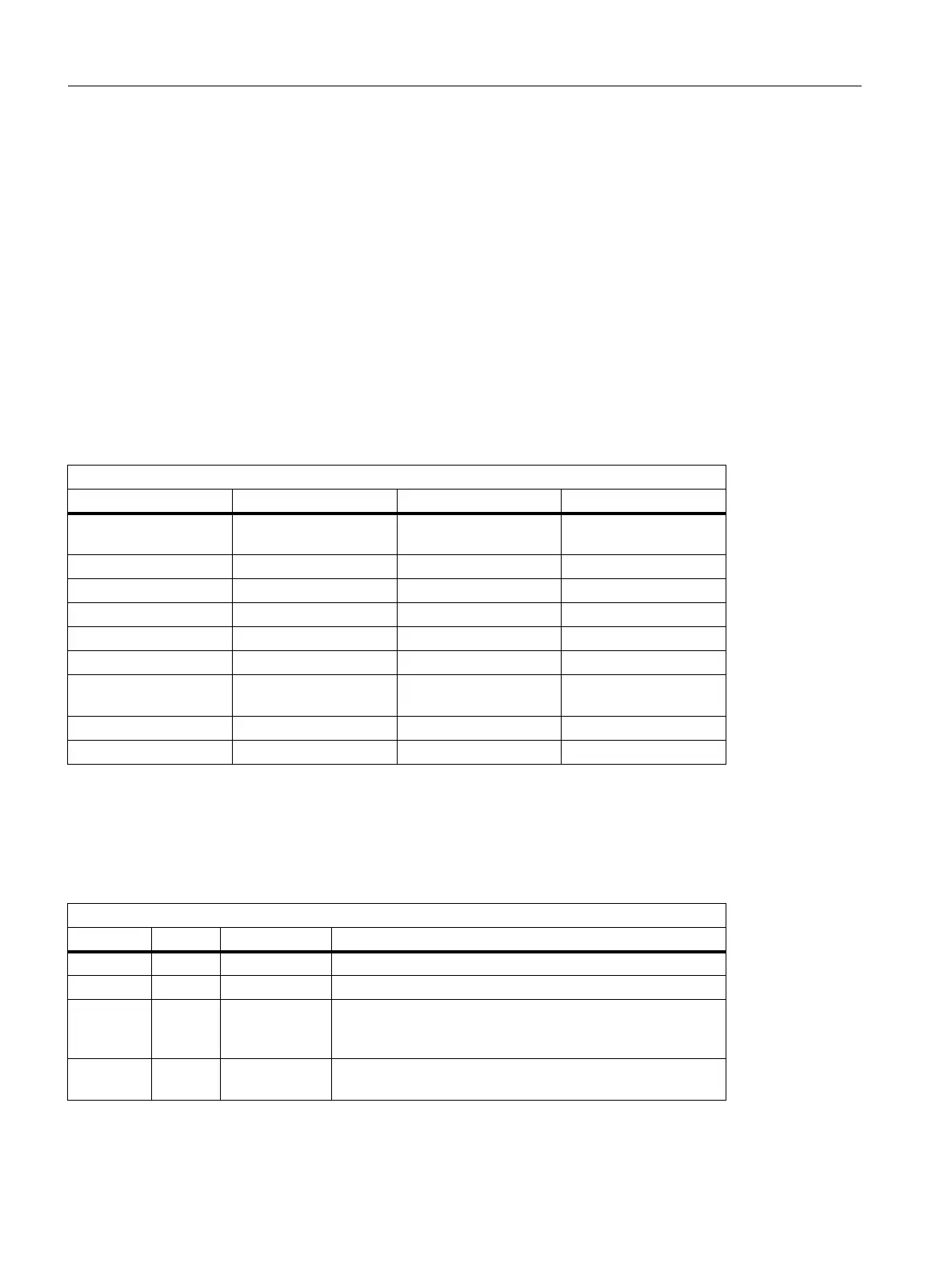

Parameterization

Signal Type Value range Meaning

PIService ANY PI.TMPCIT Set increment value for workpiece counter

Unit INT 1 ... 10 TOA

WVar1 WORD 0 ... max. Spindle number; corresponds to the type index in the

location data with spindle location type of the buffer

magazine in channel.000 = main spindle

WVar2 WORD 0 ... max. Increment value; indicates the number of spindle revolutions

after which the workpiece counter is incremented

Loading...

Loading...