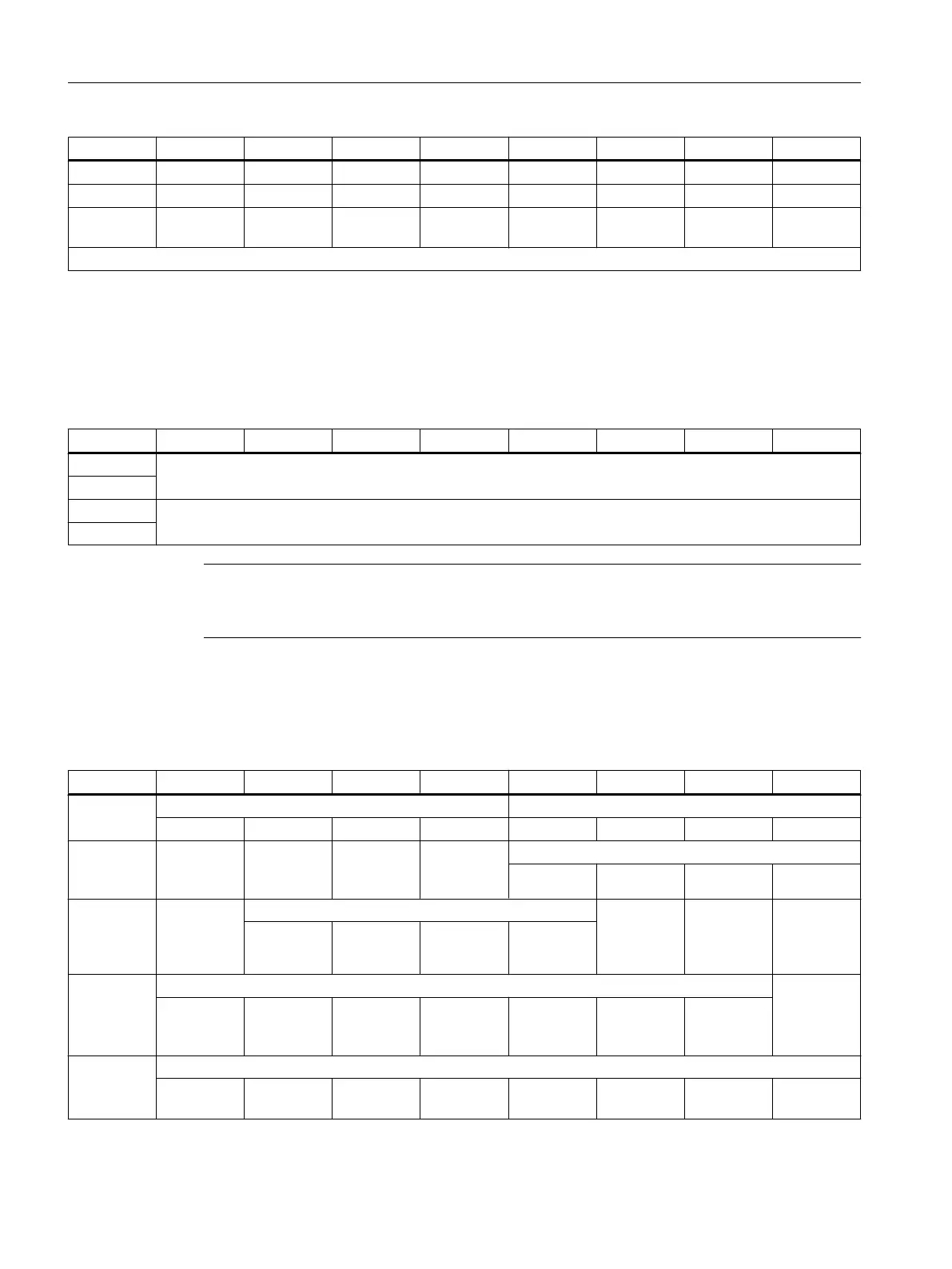

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

EB123 - - - - - - - KT-IN9

EB124 - - - - - - - -

EB125 - - - X31

pin 6

1)

X31

pin 7

1)

X31

pin 8

1)

X31

pin 9

1)

X31

pin 10

1)

Signals marked with * are inverse signals.

1) If the 4-stage spindle override rotary switch on X31 is replaced by a 5-stage rotary switch, the information here can be

measured in 5 stages.

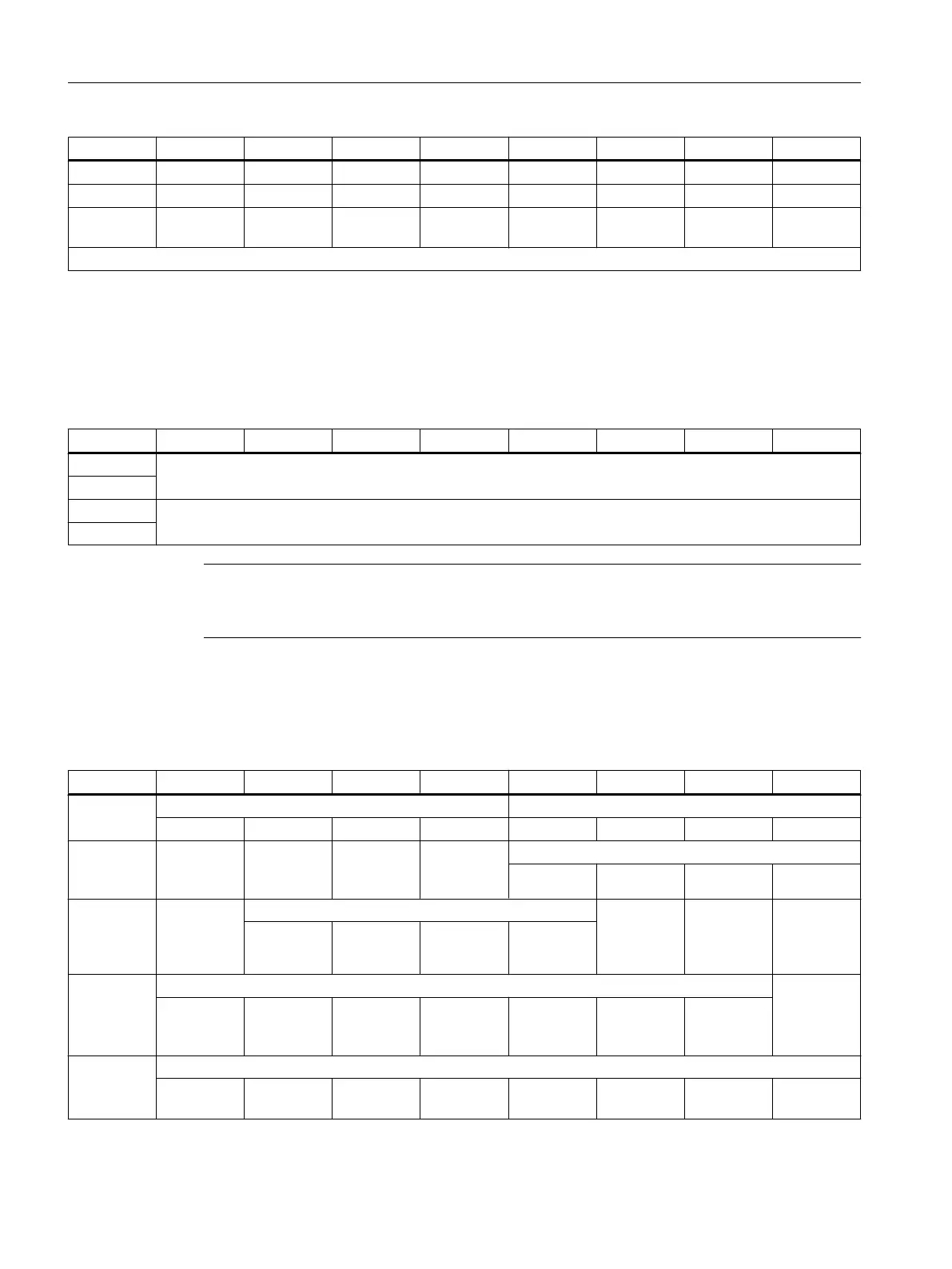

Input image of the handwheel

Table 7-14 Input image for handwheel data

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

EB m + 0 Handwheel 1 counter status

(16-bit signed, low-order byte equals byte m + 0)

EB m + 1

EB m + 2 Handwheel 2 counter status

(16-bit signed, low-order byte equals byte m + 2)

EB m + 3

Note

Within the SINUMERIK control, the handwheel data is processed directly by the NC and is not

available to the PLC.

Output image

Table 7-15 Output image MCP 483C PN

Byte Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

AB112 Machine function Operating mode

1000 INC 100 INC 10 INC 1 INC JOG TEACH IN MDI AUTO

AB113

Feed

start

*Feed

stop

NC

start

*NC

stop

Machine function

REPOS REF. var. INC 10000 INC

AB114 Direction

key

-

R13

Axis selection

Single

block

Spindle

start

*Spindle

stop

X

R1

4. axis

R4

7. axis

R7 R10

AB115 Axis selection Direction

key

+

R15

Z

R3

5. axis

R5

Drive com‐

mand in

MCS/WCS

R11

9. axis

R9

8. axis

R8

6. axis

R6

AB116 Freely assignable customer keys

T9 T10 T11 T12 T13 T14 T15 Y

R2

Anschließbare Komponenten

7.3 MCP 483C PN

PPU and components

132 Manual, 05/2015, 6FC5397-2DP40-3BA4

Loading...

Loading...