HRX-OM-X037

Chapter 2 Name and Function of Parts

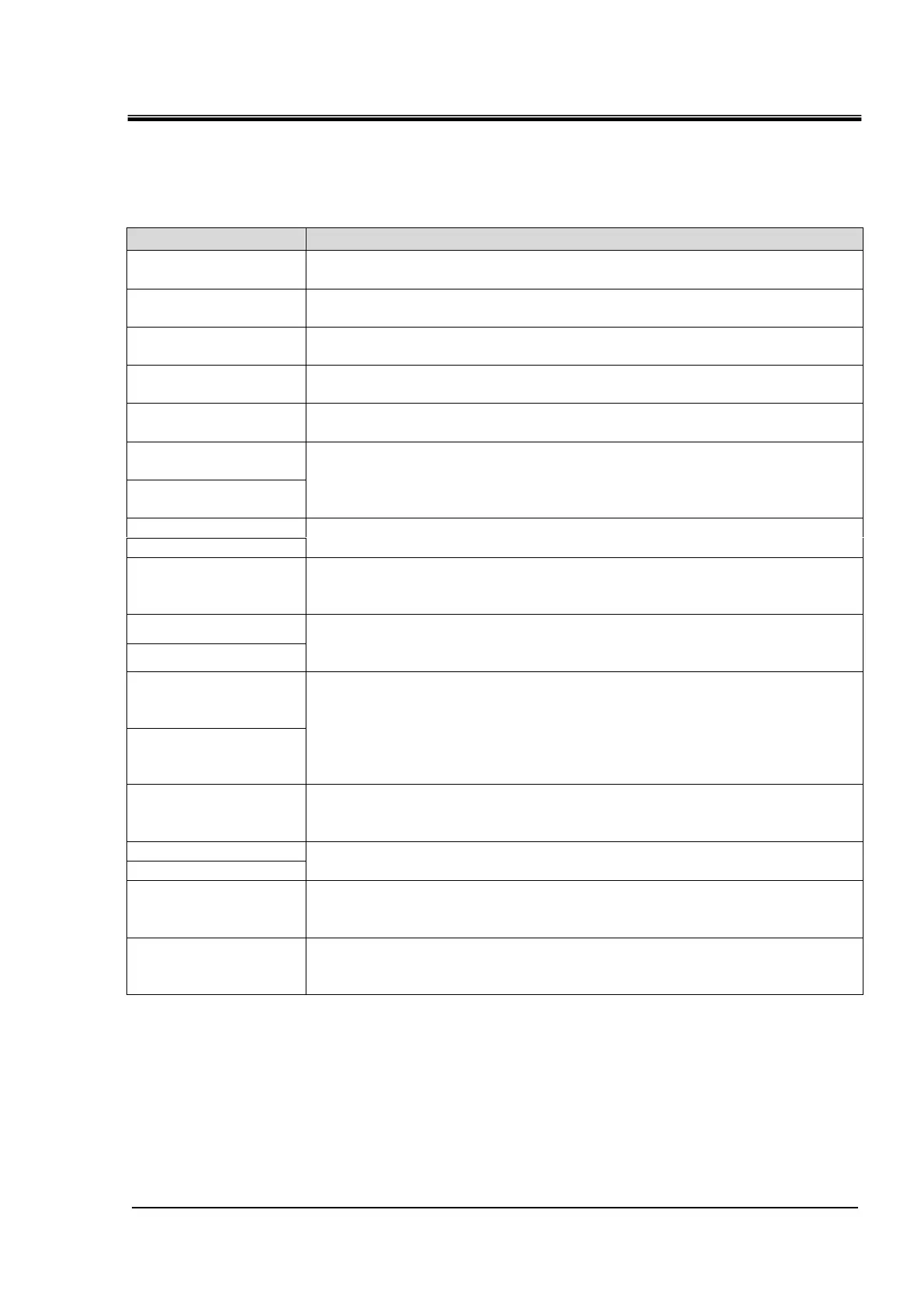

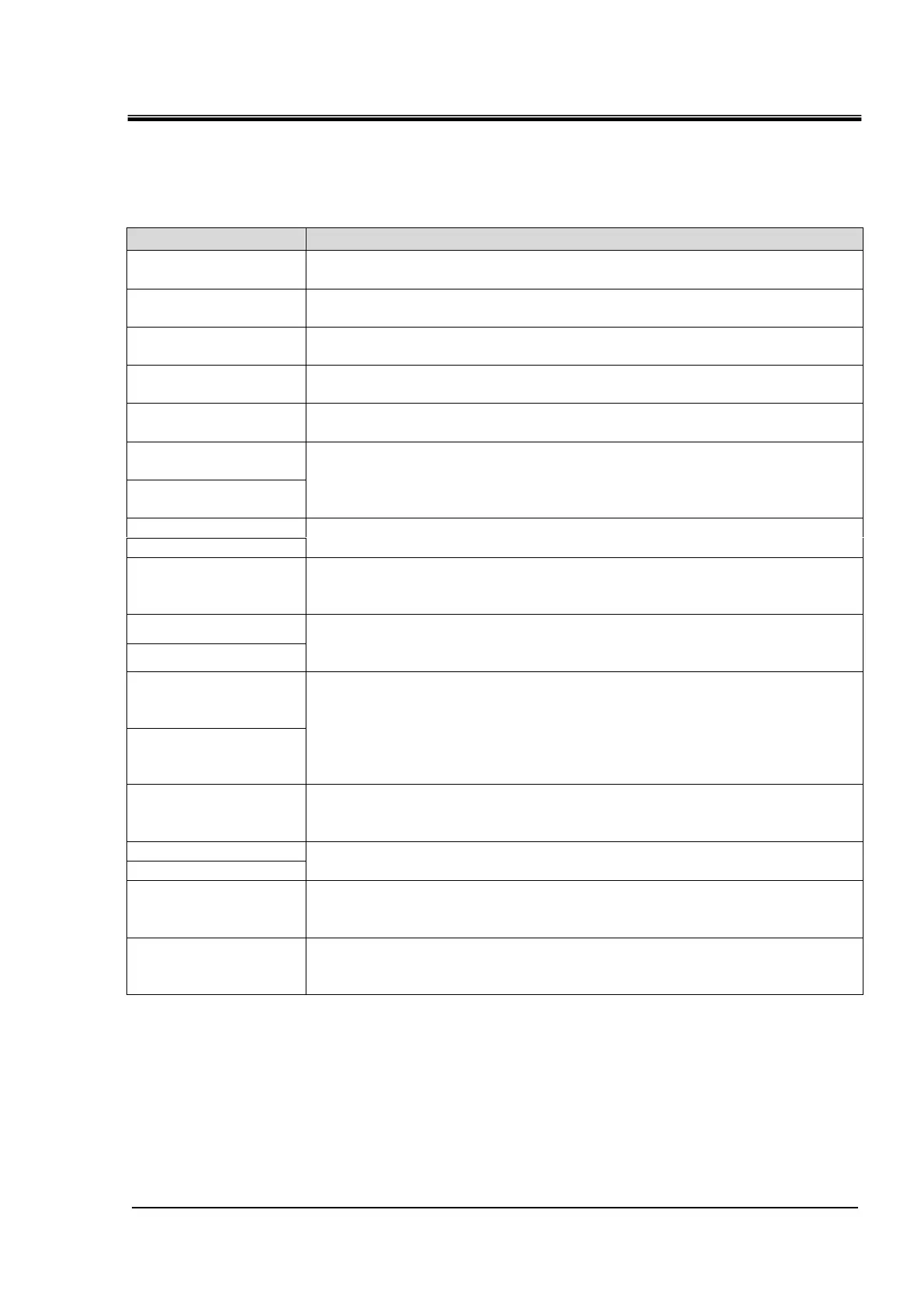

HRL Series 2.3 Function of Parts

2.3 Function of Parts

The function of parts is as follows.

Table 2.3-1 Function of parts

Operational settings for the product. Example: Run and stop product.

Performance setting

Indicates the circulating fluid level of the tank. Confirm the level is

between HIGH and LOW. For details, refer to “3.5 Circulating Fluid Supply”.

Shows the product information, such as model number and serial

number. For details, refer to ‘’1.4 Product Label’.

Circulating fluid

outlet port (CH1)

The circulating fluid flows out from the outlet port.

For laser source.

Circulating fluid

outlet port (CH2)

The circulating fluid flows out from the outlet port.

For optical systems.

Circulating fluid

return port (CH1)

The circulating fluid returns to the return port.

Circulating fluid

return port (CH2)

This drain port to drain the circulating fluid out of the tank.

Inserted to prevent dust and contamination clinging to the air cooled

condensers directly.Clean the filter periodically.

For details, refer to “8.2.2 Monthly check”.

Insert the power cable to the power cable entry and connect it

to the power terminal. For details, refer to “3.3.2 Electrical wiring”

and “3.3.3 Preparation and wiring of power supply cable”.

Insert the signal cable to the signal cable entry and connect it to

the signal connectors. For details, refer to “3.3.5 Wiring of the Run/Stop

signal input”, “3.3.6 Wiring of the contact output signal”, “3.3.7 Wiring of

analog output signal”,“3.3.8 RS-485 communication wiring”,

“3.3.9 RS-232C communication wiring” or the Operation

Manual Communication Function.

Earth leakage breaker

/ Breaker handle

Shuts off the power supply to the internal equipment of the product.

(Parts energized remained in the product.)

Refer to “3.3.2 Electrical wiring” for the earth leakage breaker.

Supply circulating fluid to the tank.

Facility water inlet

(For Water-cooled

type)

A facility water inlet to which the facility water is fed through piping.

The pressure of facility water should be in a range of 0.3 to 0.5MPa.

Facility water outlet

(For Water-cooled

type)

A facility water outlet from which the facility water returns to the user’s

machine through piping.

Loading...

Loading...