IV-10

HYDRAULIC UNITSHST PUMP

DISASSEMBLY AND ASSEMBLY

General Cautions

• Carry out disassembly and assembly operations

in a clean place and provide clean containers to

place the disassembled parts in.

• Before disassembly, clean around the ports and

remove the paint from each joint using a wire

brush.

• Clean all disassembled parts in cleaning solvent.

Use a lint free cloth, or air dry the parts.

• Make match marks on each part so that they will

be assembled in the same positions when as-

sembled.

• Replace all seals with new ones each time the

hydraulic units is disassembled.

• Check each part to make sure there is no abnormal

wear or seizing and use sandpaper, etc. to remove

any burrs, sharp edges, etc.

• Do not turn adjusting screws if not required.

• Apply hydraulic oil to sliding surfaces and apply

a thin coating of grease to seals when assembling

them.

Disassembly

Pump

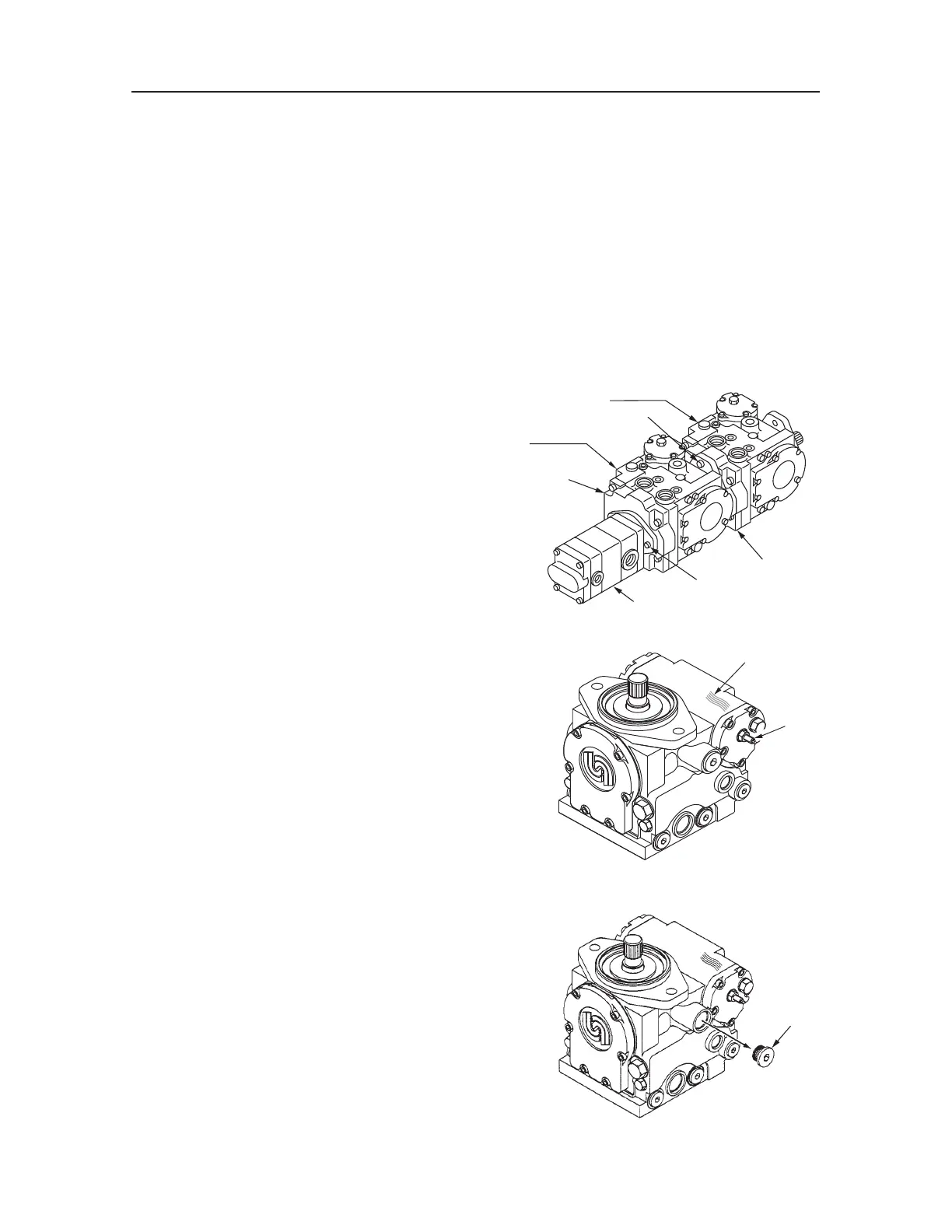

1. Disassemble the pumps P1 and P2, and the gear

pump.

• Before starting, make match marks on the

components to be disassembled for accurate

later reassembling.

a. Remove the two cap screws (25), and remove

the gear pump (2) from the A pad adapter

(3). Then remove the O-ring from the A pad

adapter (3).

b. Remove the two bolts (4) to separate the

hydraulic pumps P1 and P2 from each other.

Then remove the O-ring from the B pad

adapter (1).

c. Attach the directional marker on the hous

-

ing.

• The directional marker should be attached

on the side from which the tie bolt (16) for

neutral adjustment projects.

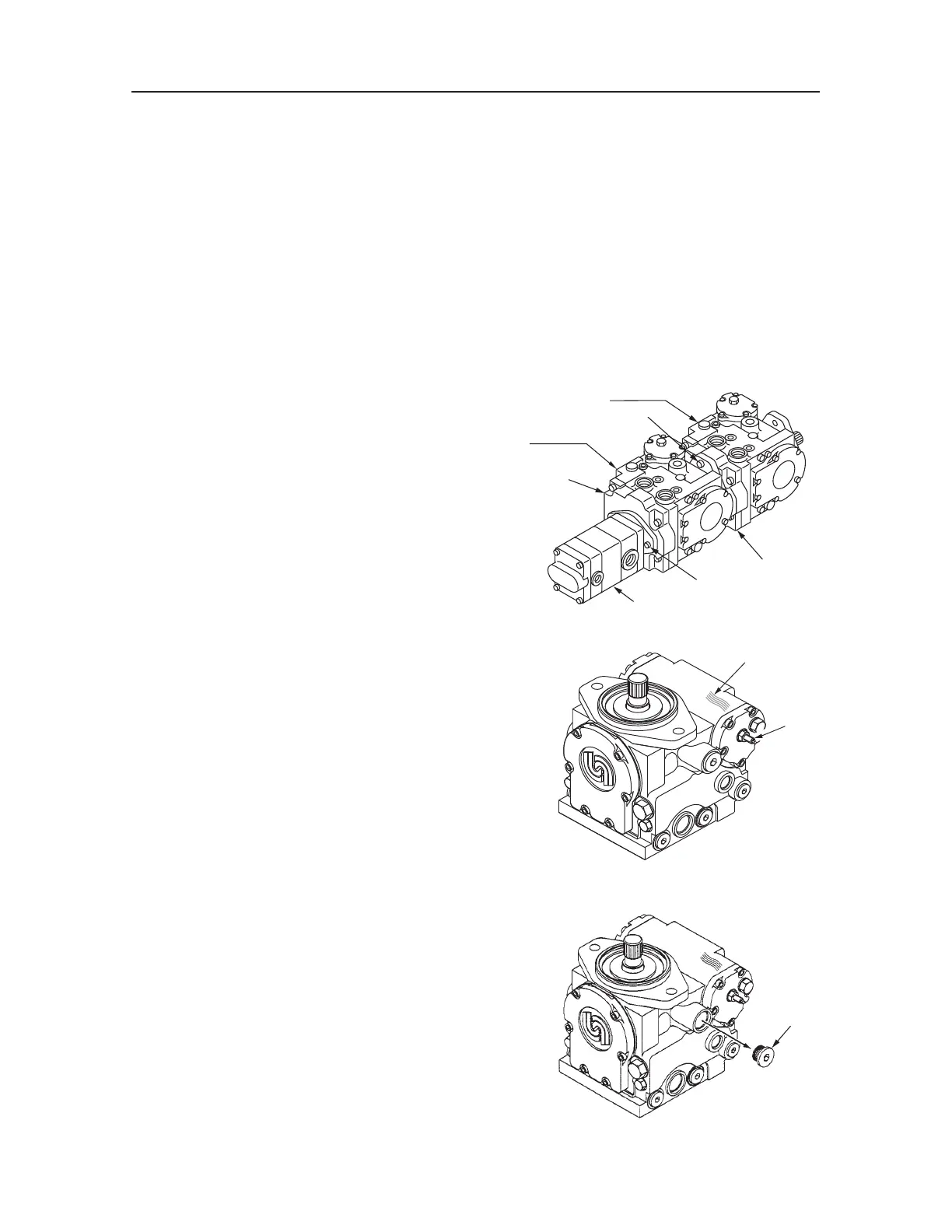

2. Remove the drain plug (5).

S3F305E

Pump P1

Pump P2

1

2

4

3

25

S3F306E

16

Mark

Loading...

Loading...