IV-34

HYDRAULIC UNITSGEAR PUMP

DISASSEMBLY AND ASSEMBLY

General Cautions

• Carry out disassembly and assembly operations

in a clean place and provide clean containers to

place the disassembled parts in.

• Before disassembly, clean around the ports and

remove the paint from each joint using a wire

brush.

• Clean each of the disassembled parts with a clean

-

ing oil such as diesel fuel.

• Make match marks on each part so that they will

be assembled in the same positions when as-

sembled.

• Replace all seals with new ones each time the

pump is disassembled, coating them lightly with

grease.

• Check each part to make sure there is no abnormal

wear or seizing and use sandpaper, etc. to remove

any burrs, sharp edges, etc.

• Adjust adjustment screws only when required.

Following is an explanation of the gear pump disas-

sembly procedure.

Follow the procedure used to disassemble the gear

pump in reverse order when reassembling it.

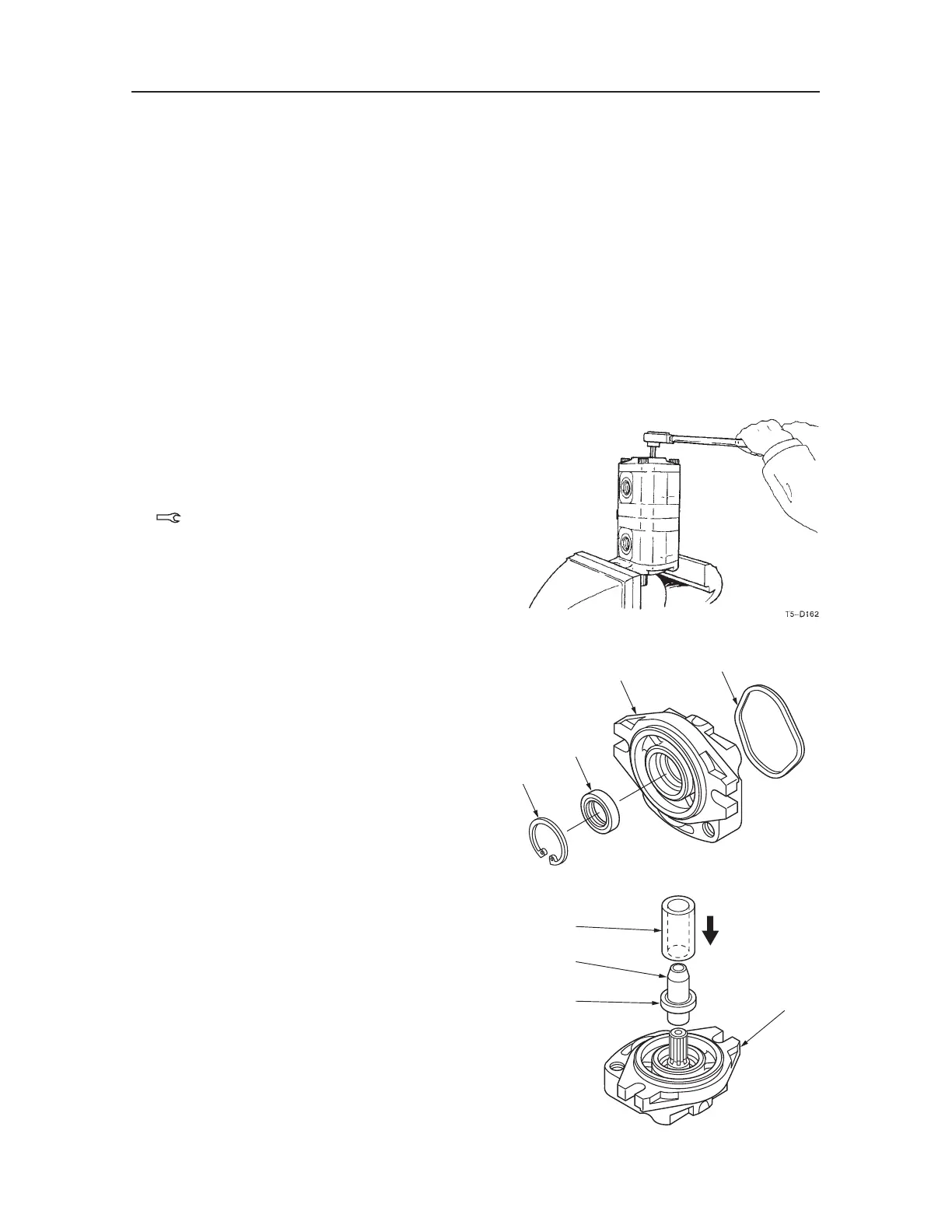

1. Remove the cap screws.

Screw: 88~93 N·m

2. Remove the flange.

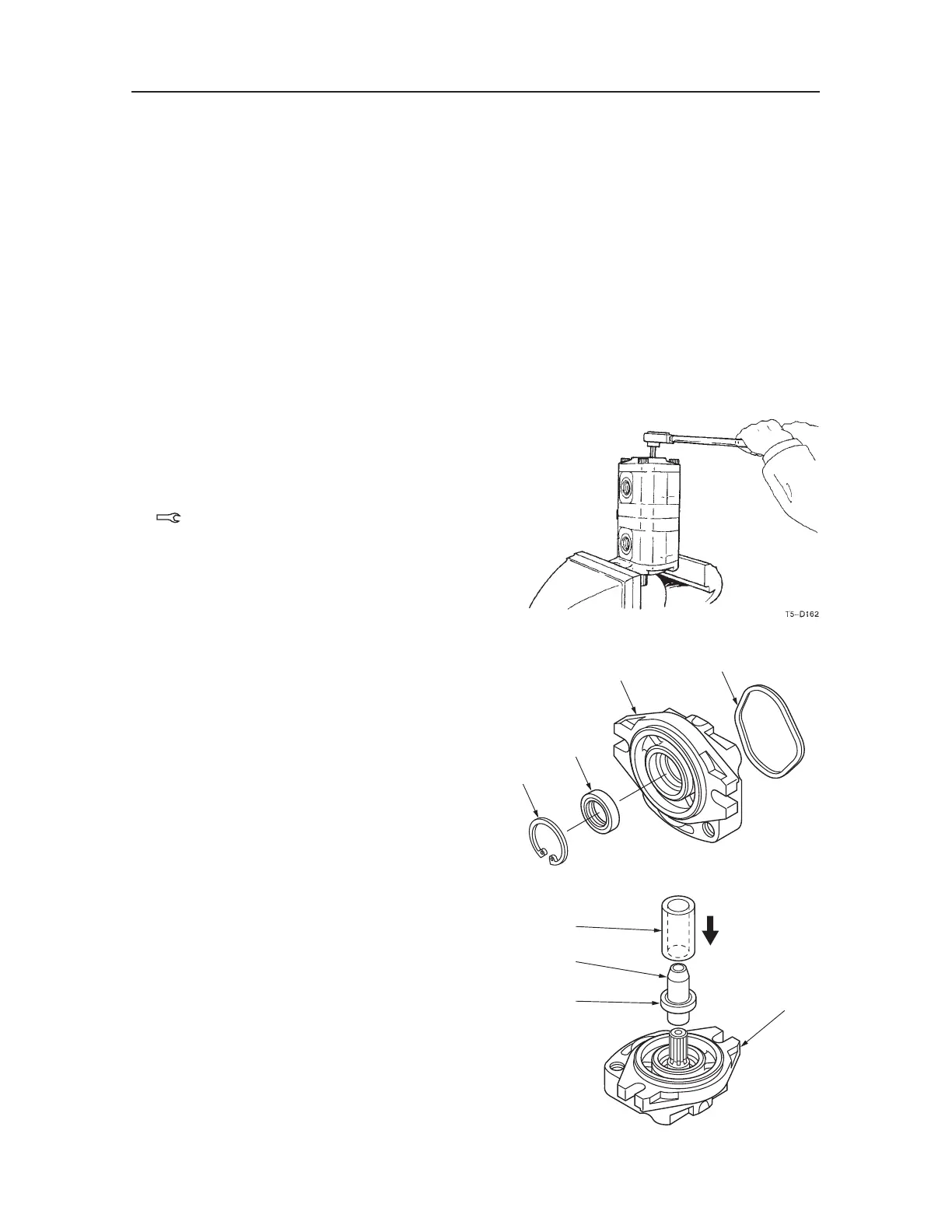

3. Remove gasket (2) from flange (1).

4. Remove snap ring (3) and oil seal (4) from flange

(1).

• Be careful not to scratch or otherwise damage

the flange.

• When re-assembling, install the oil seal using

the jigs A and B.

T7D151

2

1

4

3

T7D152

B

A

4

1

Loading...

Loading...