DCO Setup and Calibration

The ‘G2xxx Value-Line devices take a slightly different approach. Rather than trimming the

silicon, as is done with the ‘FR5xxx devices, the factory stores calibration values into each

device’s Flash memory (INFOA section) during device test.

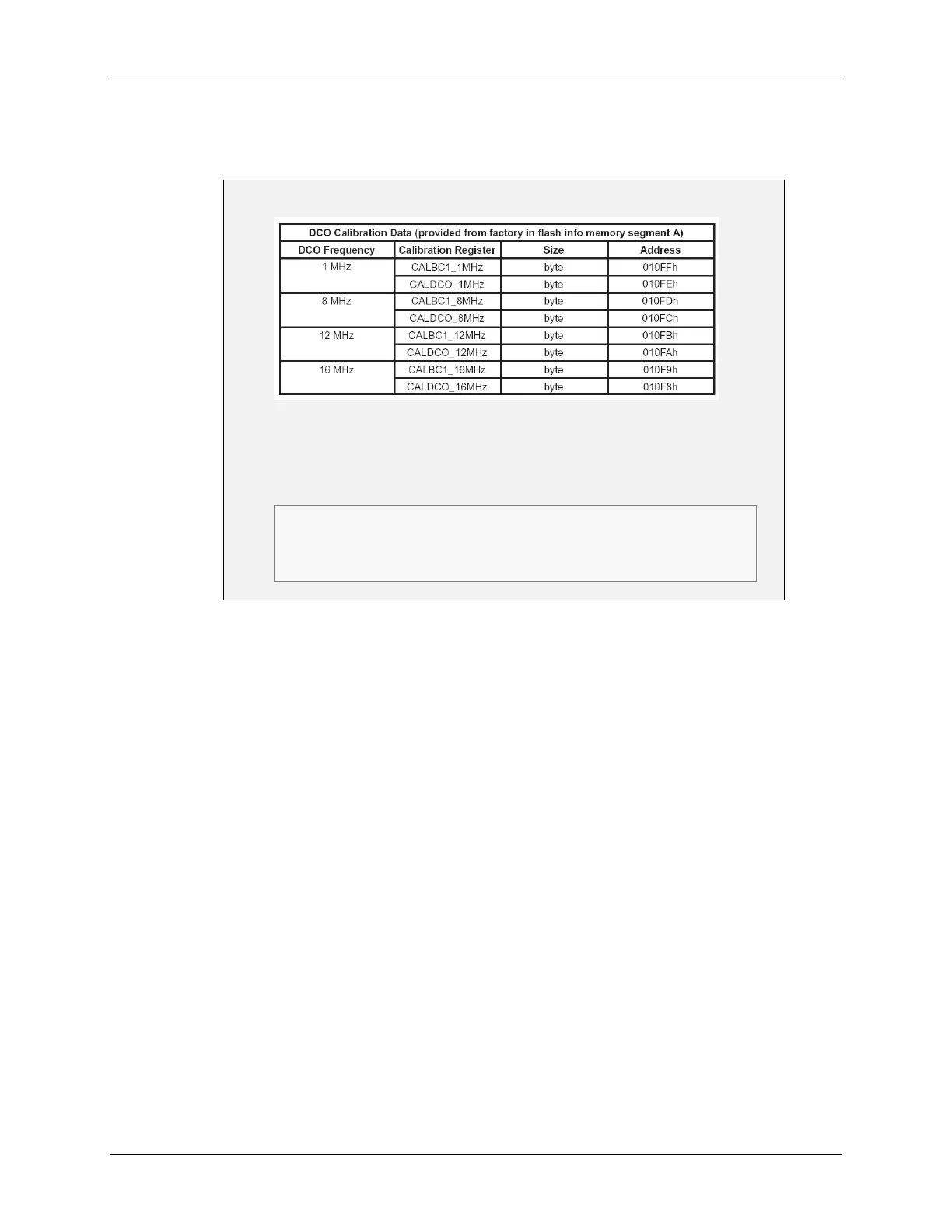

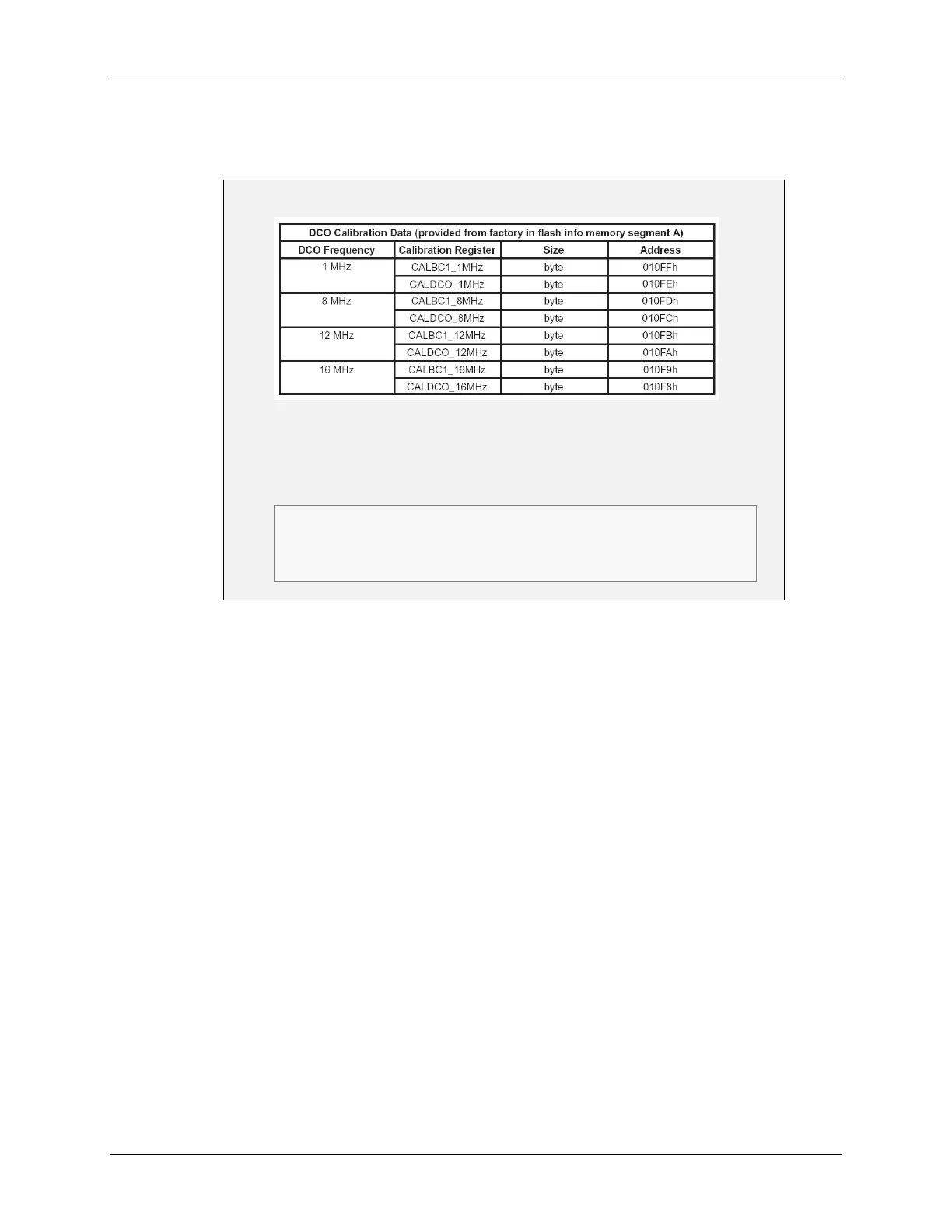

‘G2xxx DCO – Calibration Constants

// Setting the DCO to 1MHz

if (CALBC1_1MHZ ==0xFF || CALDCO_1MHZ == 0xFF)

while(1); // Erased calibration data? Trap!

BCSCTL1 = CALBC1_1MHZ; // Set range

DCOCTL = CALDCO_1MHZ; // Set DCO step + modulation

Most G2xx devices provide pre-calibrated clock settings – applying

these sets the Range, DCO, and MCO values

Clock (and ADC) calibration values are calculated at the factory and

stored into Flash memory (INFOA)

G2xx1 provide 1MHz calibration; G2xx2/3 provides all 4 frequencies

Basically, the device tester measures the silicon to determine what value of DCO and MOD is

required to run the DCO at a set of pre-determined frequencies. These calibration values are

stored into INFOA memory by the tester. You can then copy the appropriate calibration constant

from Flash into your DCO control register to run the clock at a specified frequency.

MSP430 Workshop - MSP430 Clocks & Initialization 4 - 27

Loading...

Loading...