GP3 Drum-Maintenance

WARNING

When performing this drum maintenance,

do the following:

• Ensure that there Is adequate

ventilation in the area.

• Use protective gloves at all times.

« Do not smoke.

• Wash your hands when the procedures

are completed.

CAUTION

These procedures must be completed in the

shortest possible time in order to reduce the

effects of light shock.

Washing Procedure

Washing Materials:

• Drum Maintenance Kit

• Film Remover

1. Remove the Drum Assembly from the

Xerographic Module (REP 9.2).

2. Put on gloves.

3. Gently remove any dry ink/toner and

developer from the surface of the drum,

using a dry polyurethane pad.

4. Apply Film Remover to a clean

polyurethane pad.

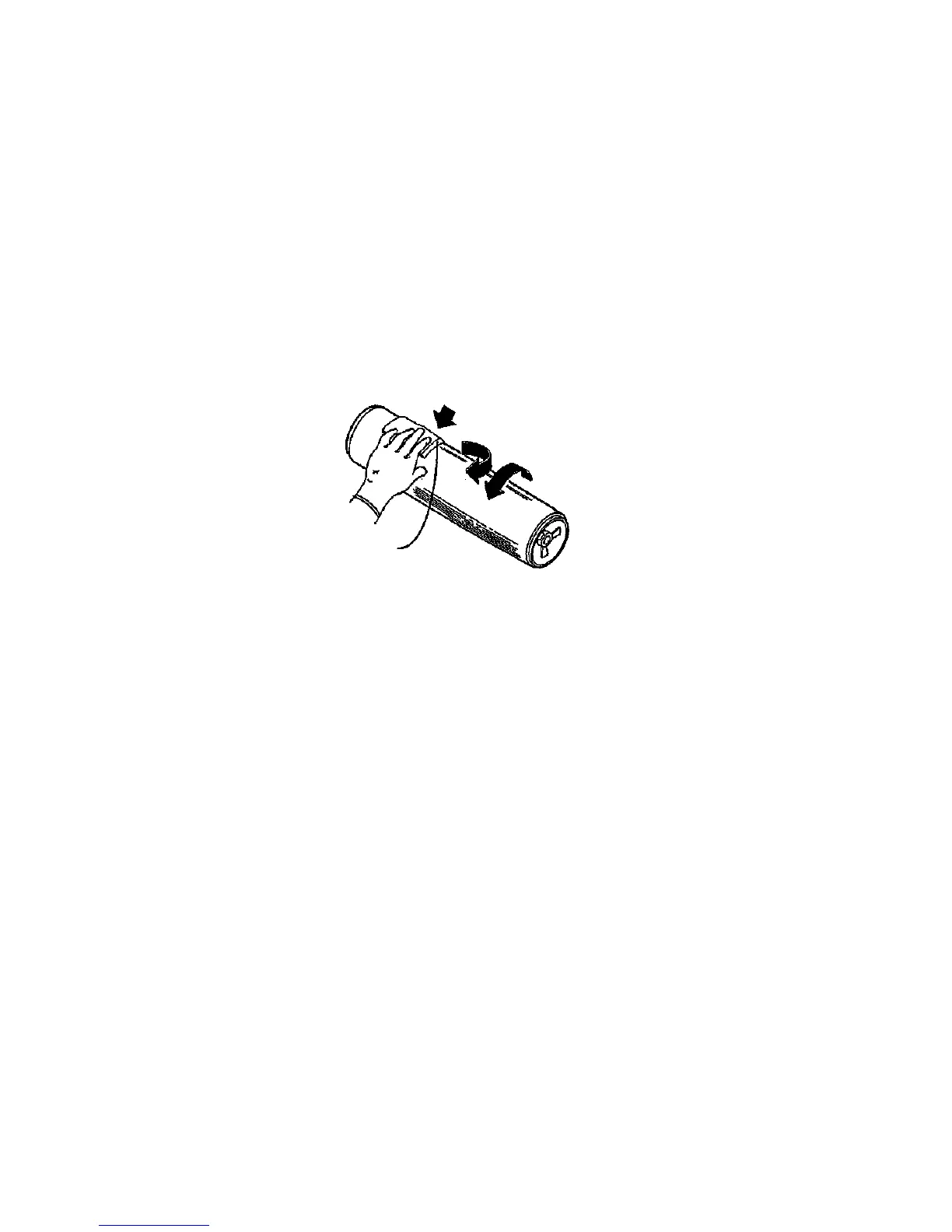

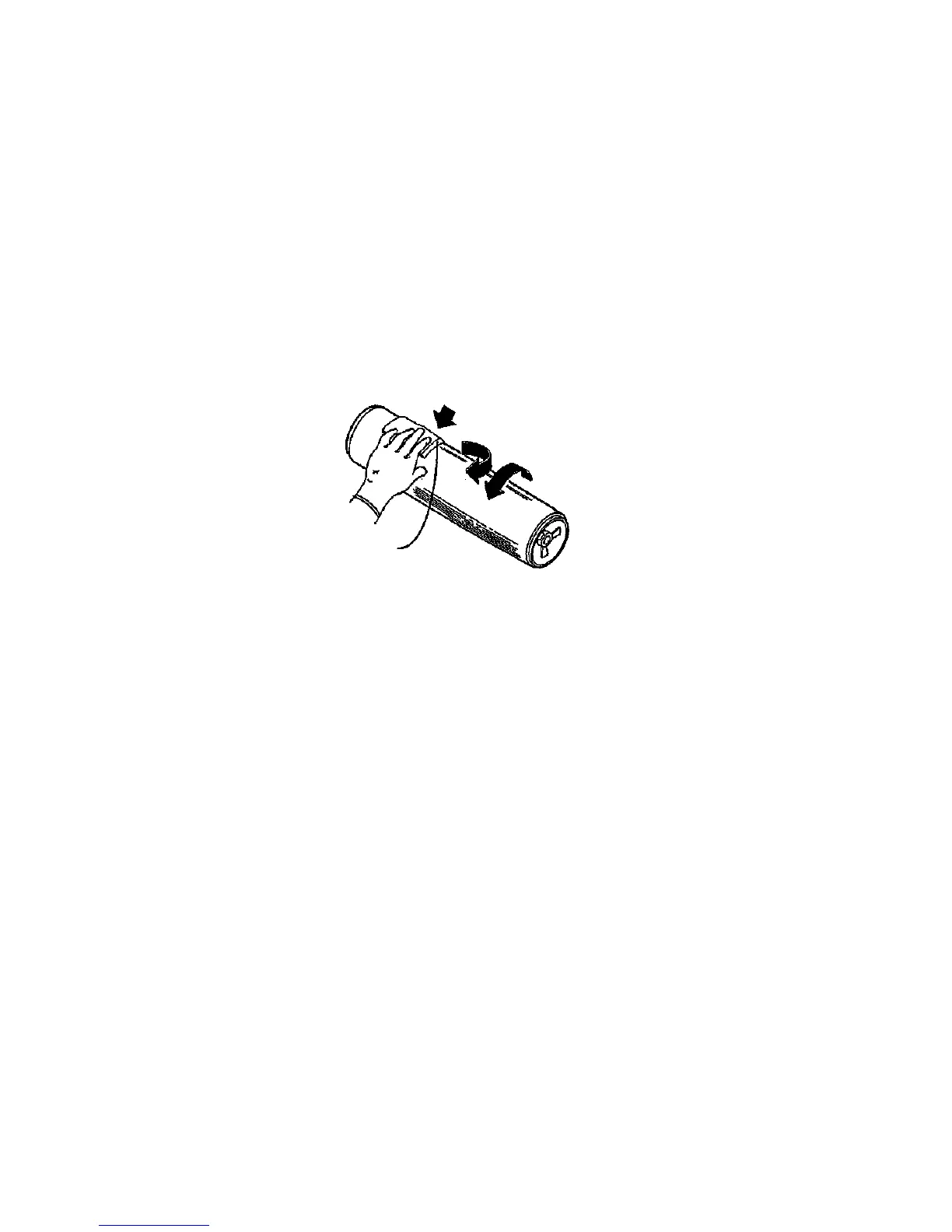

5. (Figure 1): Wash the drum from end to

end, using a circular motion.

NOTE: Ensure that the ends of the drum are

washed.

6.

7.

8.

9.

Minimum

pressure

Polyurethane

pad

Figure 1. Washing the Drum

Using the clean side of the polyurethane

pad, continue washing the drum until the

entire surface of the drum is covered with

film remover.

Allow enough time for the air to dry the

surface of the drum.

Use the dusting pouch to apply a thin layer

of Zinc Stearate (8R181) over the entire

surface of the drum.

Buff the surface of the drum using the

clean side of the dry polyurethane pad.

NOTE: Ensure that the ends of the drum are

buffed as well as the center of the drum.

10. Continue to buff the surface of the drum

for three complete revolutions of the drum.

11. Apply a final thin layer of Zinc Stearate

over the entire surface of the drum.

12. Reinstall the drum.

13. Enter the diagnostic mode. Enter test

[1004} and allow the printer to run for five

more minutes.

14. Place the used washing materials in the

disposal bag.

15. Wash your hands.

GP3 Drum Maintenance

1/98

6-12

8830

Loading...

Loading...