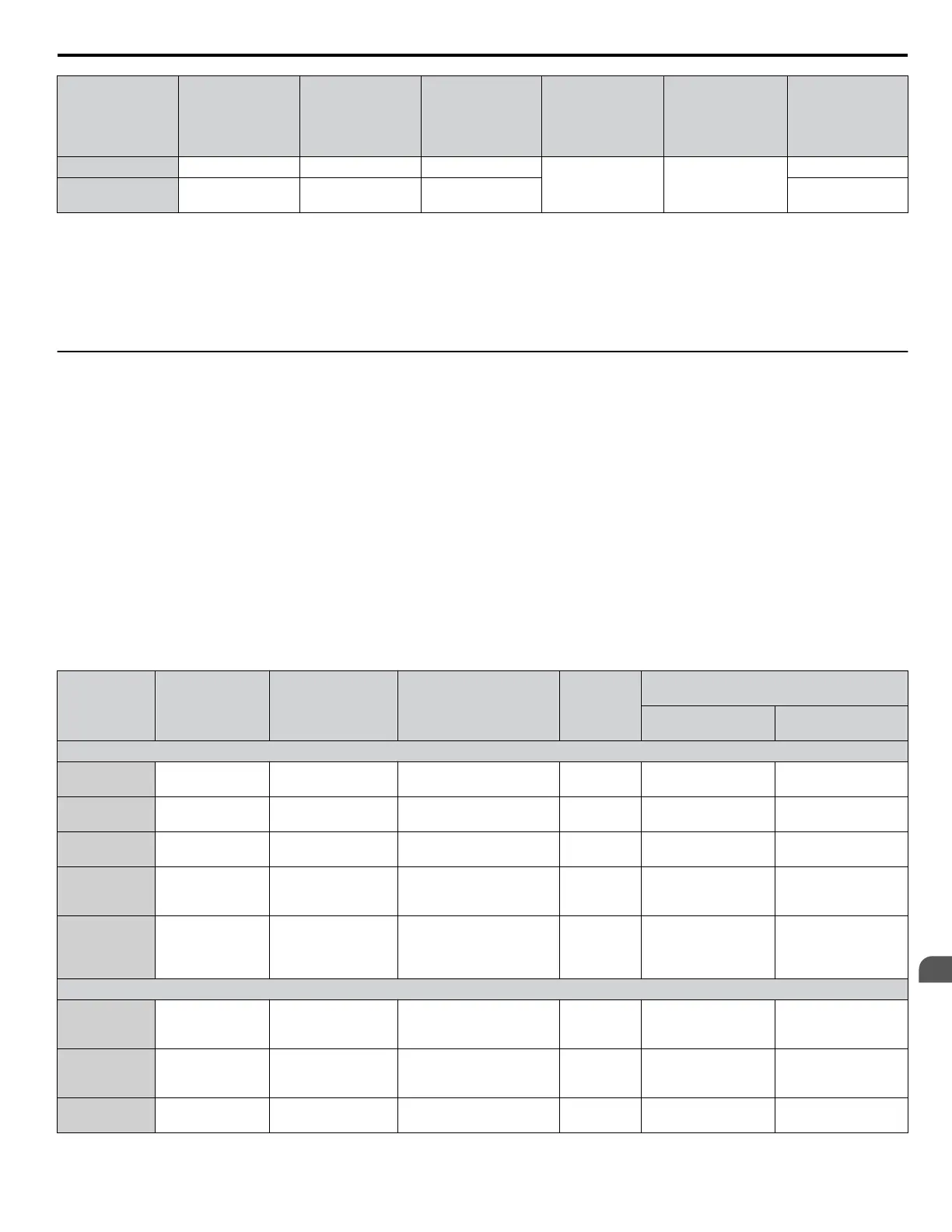

Model

Nominal Output

Power (HP)

AC Drive Input

(A)

MCCB Rating (A)

<1>

Time Delay Fuse

Rating (A)

<2>

Non-time Delay

Fuse Rating (A)

<3>

Bussmann

Semiconductor

Fuse Model

(Fuse Ampere)

<4>

4A0480 400 480 900

<5> <5>

FWH-700A (700)

4A0590 500 590 1100

FWH-1000A

(1000)

<1> Maximum MCCB rating is 15 A, or 200% of drive input current rating, whichever value is larger. MCCB voltage rating must be 600 Vac or greater.

<2> Maximum Time delay fuse is 175% or drive input current rating. This covers any Class J, T, or CC fuse.

<3> Maximum Non-time delay fuse is 300% of drive input current rating. This covers any Class J, T, or CC fuse.

<4> When using semiconductor fuses, Bussmann FWH fuses are required for UL compliance.

<5> Consult factory.

<6> Class L fuse is also approved for this rating.

u

Attachment for External Heatsink Mounting

An external attachment can be used to project the heatsink outside of an enclosure to ensure that there is sufficient air circulation

around the heatsink.

n

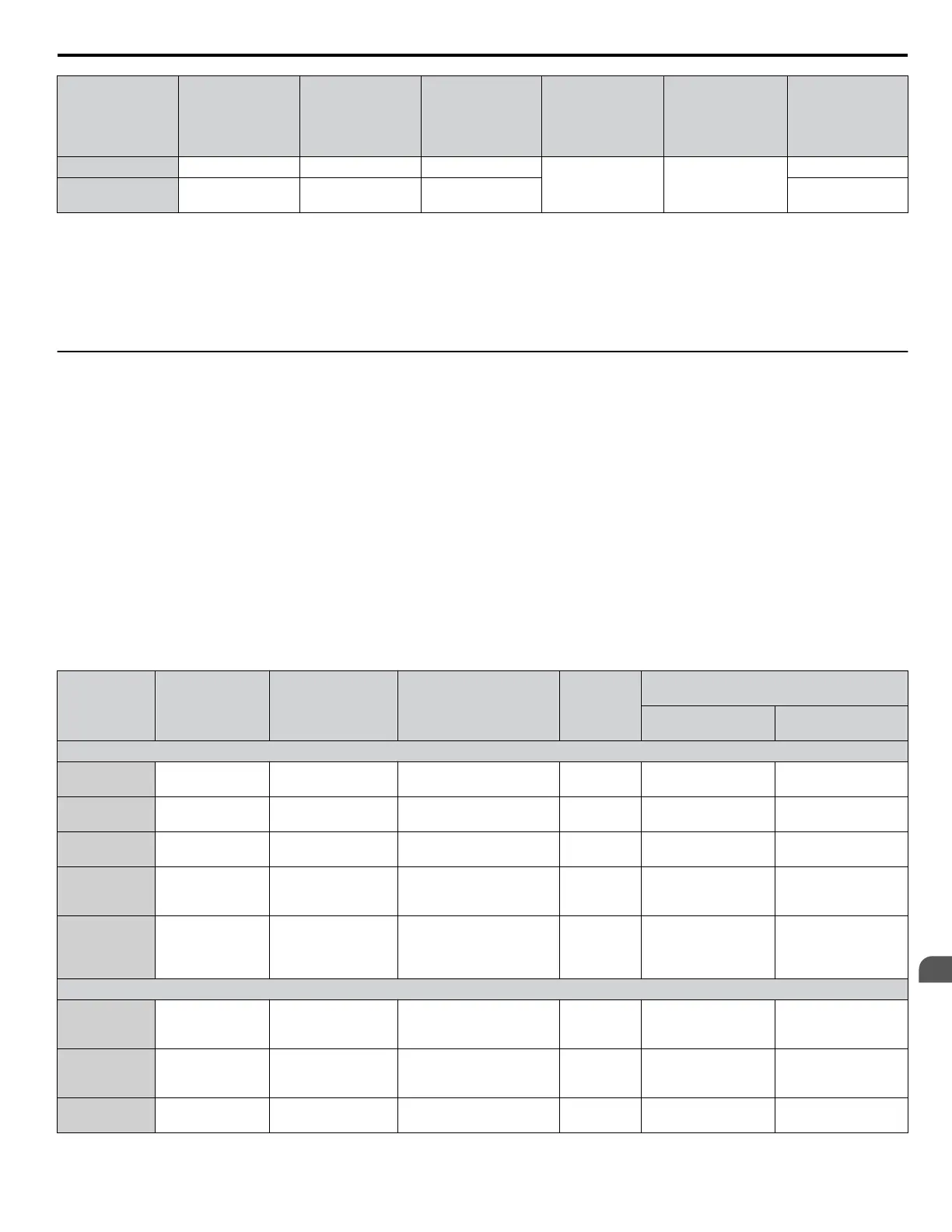

IP20 NEMA 1, UL Type 1 Heatsink-External Mounting Attachment

Table 6.4 shows the heatsink-external mounting attachment for an IP20 NEMA 1, UL Type 1 enclosure.

Order parts according to the corresponding product codes in Table 6.4 and install them according to document EZZ021811.

Refer to Table 6.6 for panel cut-out dimensions.

NOTICE: Tighten the installation screws for the bracket and the attachment to the specified tightening torque. Dust can enter if the screw

is loose, and may cause the drive to break down.

NOTICE: If the environment outside the diecast case is relatively harsh, then use either a sealant or a gasket to ensure that the attachment

is firmly affixed. Refer to Table 6.6 for installation details.

NOTICE: The bracket and attachment must match the direction of the installation. Water and dust can enter when the bracket and attachment

are installed incorrectly, and may cause the drive to break down.

Table 6.4 IP20 NEMA 1, UL Type 1 Attachment Code List

Model

Product Code Product Text Parts List

Weight

kg (lb)

Recommended Mounting Hardware

(Not Provided)

Screw Size

Tightening Torque

N·m (lb. in.)

Three-Phase 200 V Class

2A0011

2A0017

100-067-550 72606 -EZZ021811A

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 8)

0.4 (0.9) Screw M5x14 (Qty. 4)

2.0 to 2.5

(17.7 to 22.1)

2A0024

2A0031

100-067-551 72606 -EZZ021811B

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 8)

0.6 (1.3) Screw M5x14 (Qty. 4)

2.0 to 2.5

(17.7 to 22.1)

2A0046

2A0059

100-067-552 72606 -EZZ021811C

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 4)

0.3 (0.7) Screw M6x14 (Qty. 4)

4.0 to 4.9

(35.4 to 43.3)

2A0075

2A0088

2A0114

100-067-553 72606 -EZZ021811D

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 2)

Screw M6x14+S+W (Qty. 2)

0.4 (0.9) Screw M6x14 (Qty. 4)

4.0 to 4.9

(35.4 to 43.3)

2A0143

2A0169

2A0211

2A0273

– – – – Screw M10x20 (Qty. 4)

17.7 to 22.5

(156.7 to 199.1)

Three-Phase 400 V Class

4A0005

4A0008

4A0011

100-067-550 72606 -EZZ021811A

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 8)

0.4 (0.9) Screw M5x14 (Qty. 4)

2.0 to 2.5

(17.7 to 22.1)

4A0014

4A0021

4A0027

100-067-551 72606 -EZZ021811B

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 8)

0.6 (1.3) Screw M5x14 (Qty. 4)

2.0 to 2.5

(17.7 to 22.1)

4A0034

4A0040

100-067-552 72606 -EZZ021811C

Bracket (Qty. 2)

Screw M5x14+S+W (Qty. 4)

0.3 (0.7) Screw M6x14 (Qty. 4)

4.0 to 4.9

(35.4 to 43.3)

6.5 Installing Peripheral Devices

YASKAWA ELECTRIC TOEP C710616 45F YASKAWA AC Drive – Z1000 User Manual

257

6

Peripheral Devices &

Options

Loading...

Loading...