Sensor test routine

stick just reaches full throttle position. If the motor turns at the maximum possible

speed much earlier or only starts to turn at a very high stick deflection, decrease the travel

of throttle channel in the transmitter or repeat the programming of the speed controller.

Thus the Governor of MICROBEAST PLUS can operate correctly, the motor speed should

increase as linear as possible when the stick is moved and there should be no ranges in that

the motor speed does not change.

With a nitro/gas powered helicopter you can simply rotate the clutch or engine crankshaft

by hand until the signal generator (magnet or similar) passes the sensor. Whenever the

signal generator is within the detection range of the sensor the Status-LED should light

up in blue color. In addition to the function control of the sensor, check the throw setting

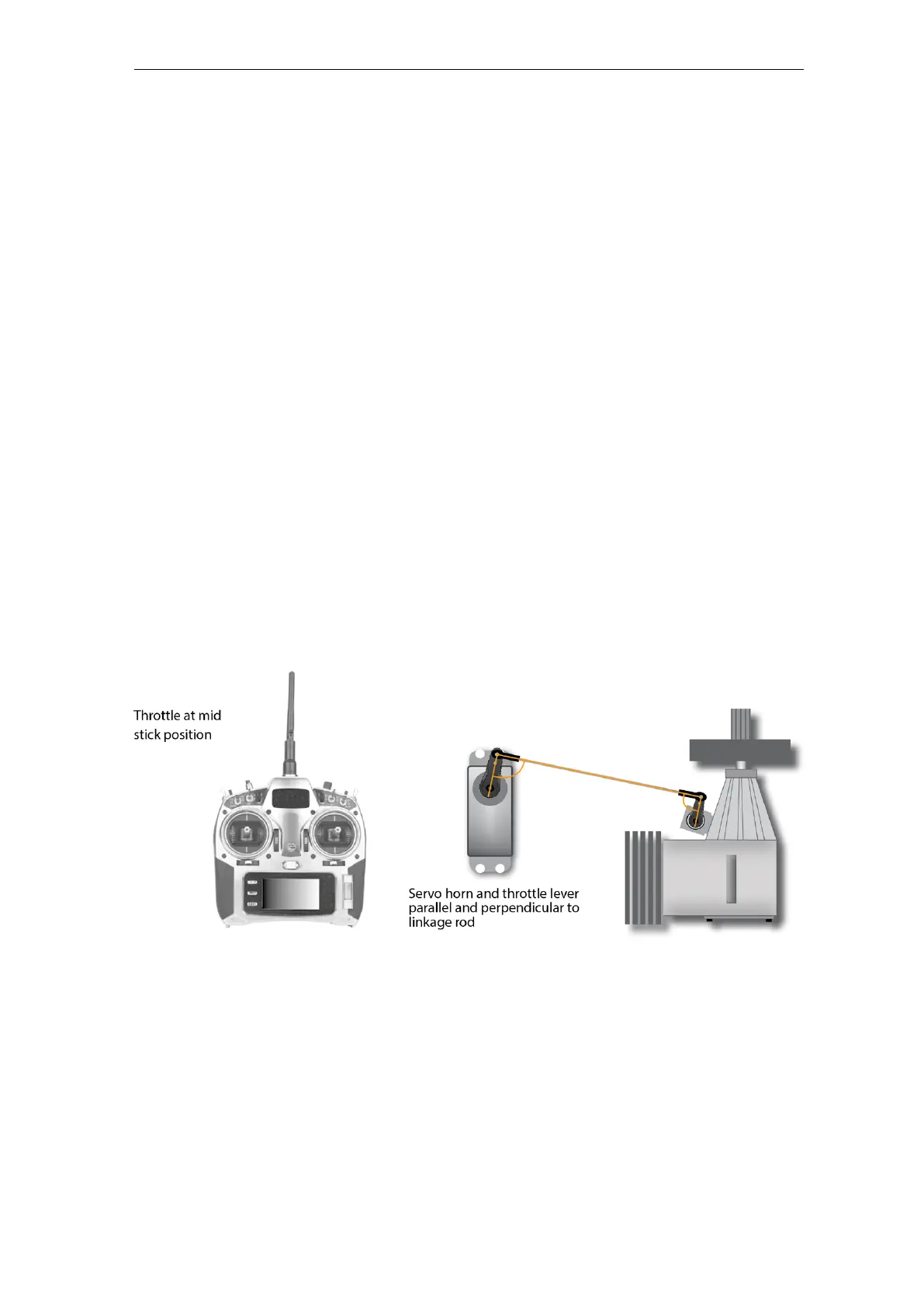

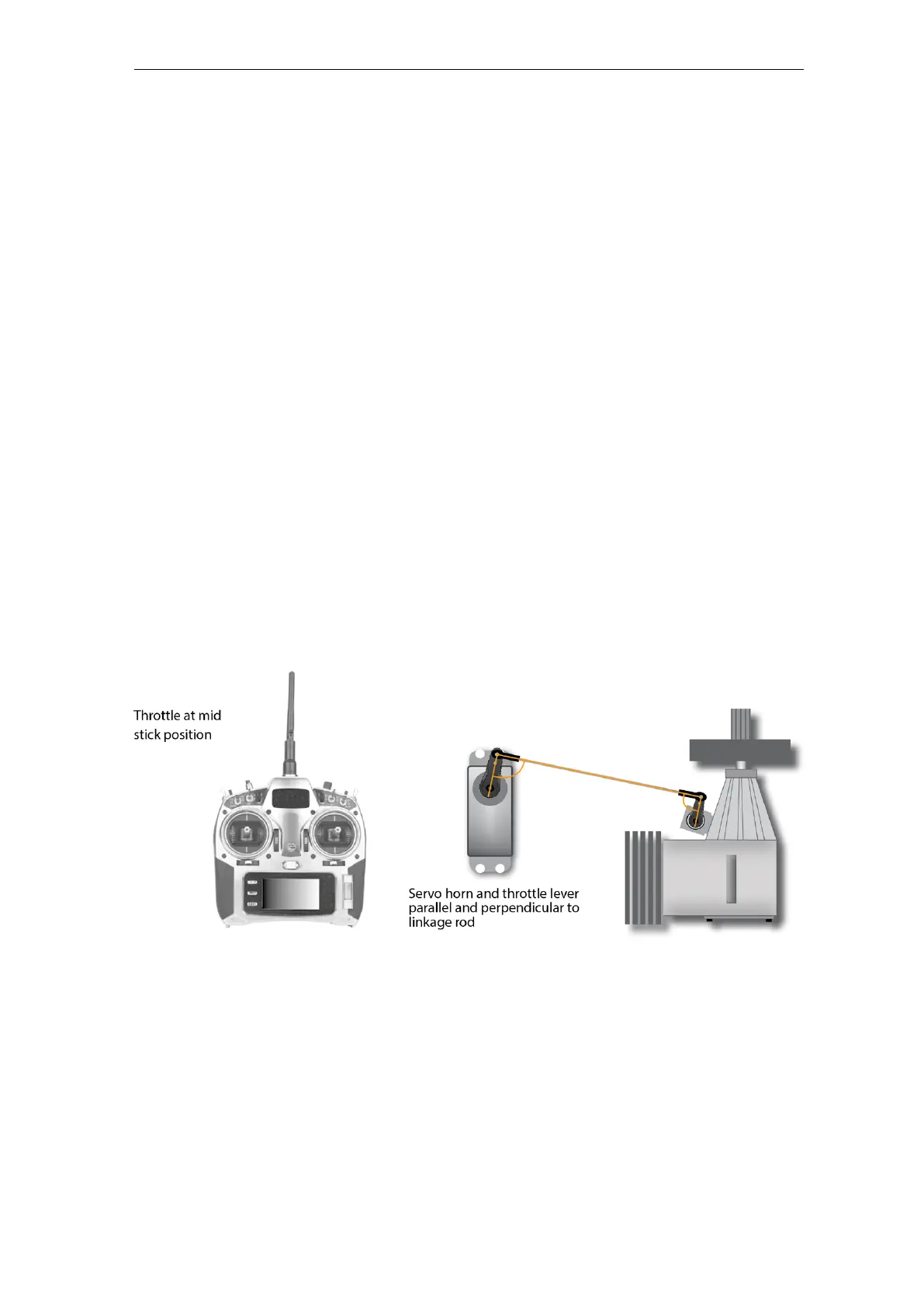

for the throttle servo in the remote control and adjust if necessary: Set the throttle to mid

stick position and attach the servo horn, so that the throttle linkage is at a right angle to

the servo horn. Then adjust the length of the linkage according to the instructions of the

helicopter, so that it also is positioned perpendicular to the linkage lever at the carburetor.

Adjust the lever at the carburetor so that it is opened halfways (note the markings on

the carburetor!). Now move the throttle stick towards full throttle and adjust the servo

travel in the transmitter accordingly, so that the full throttle position is reached without

binding. Lastly move both throttle stick and throttle trim on the transmitter to the „motor

off“ position and also adjust the servo travel in that direction until the carburetor is fully

closed. If the servo travel must be greatly reduced in both directions, it is recommended

that the linkage ball on the servo arm is mounted further in so that the servo can be

moved over a wider range. For more information refer to the instruction manual for your

helicopter.

Figure 111

182

Loading...

Loading...